Unidirectional rotation servo turret

A turret, one-way technology, applied in the field of CNC lathes, can solve the problems of cutting fluid or environmental pollution, low reliability of hydraulic components, poor precision, etc., and achieve simple and reliable movements, simple and reliable connections, and no noise control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

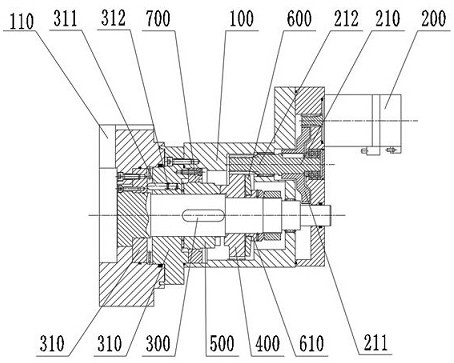

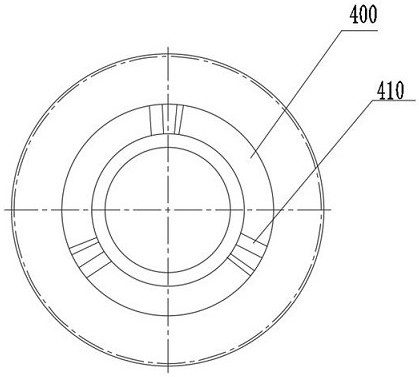

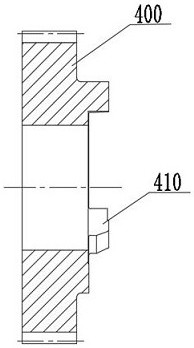

[0020] like Figure 1~5 As shown, a one-way rotary servo turret includes a box body 100, a cutter head 110, a servo motor 200, and a main shaft 300 are installed on the box body 100, and a main gear 400, a cam 500, a disc spring 600 and a one-way The clutch 700, the servo motor 200 drives the main gear 400 through the transmission assembly 210 to drive the main shaft 300 to rotate, the disc spring 600 is offset against one side of the main gear 400, and the other side of the main gear 400 is provided with several bumps 410, and the cam 500 is connected to The bumps are correspondingly provided with grooves 510 , and the grooves 510 include straig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Slope | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com