Sawtooth machining device for hard alloy saw blade and implementation method of hard alloy saw blade

A cemented carbide and processing device technology, applied in metal processing equipment, metal processing mechanical parts, tool manufacturing of sawing machine devices, etc. , Improve the effect of fixing firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

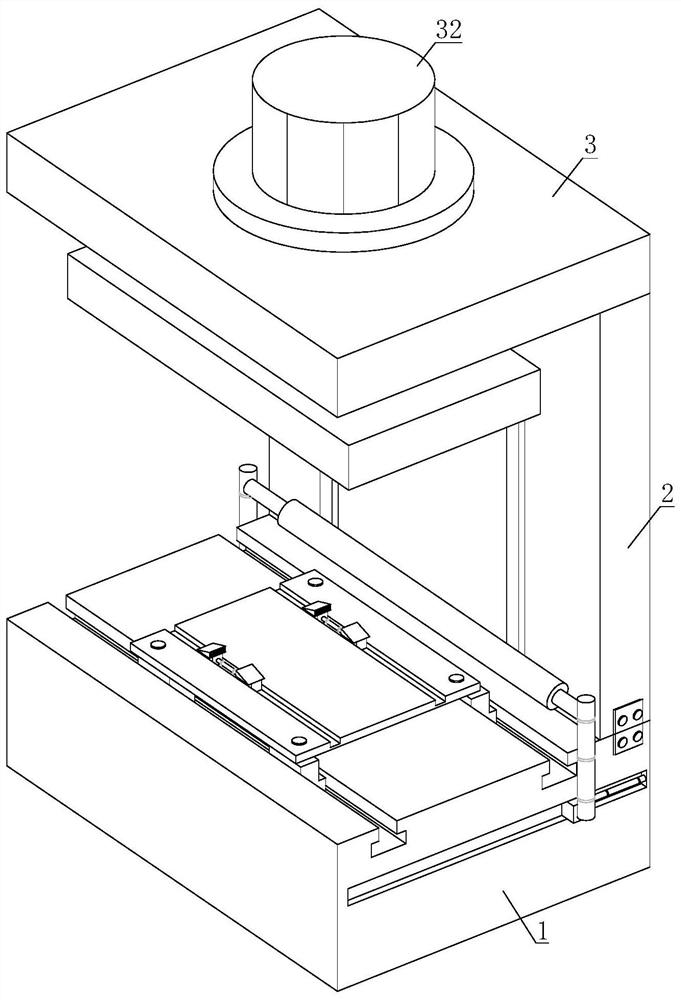

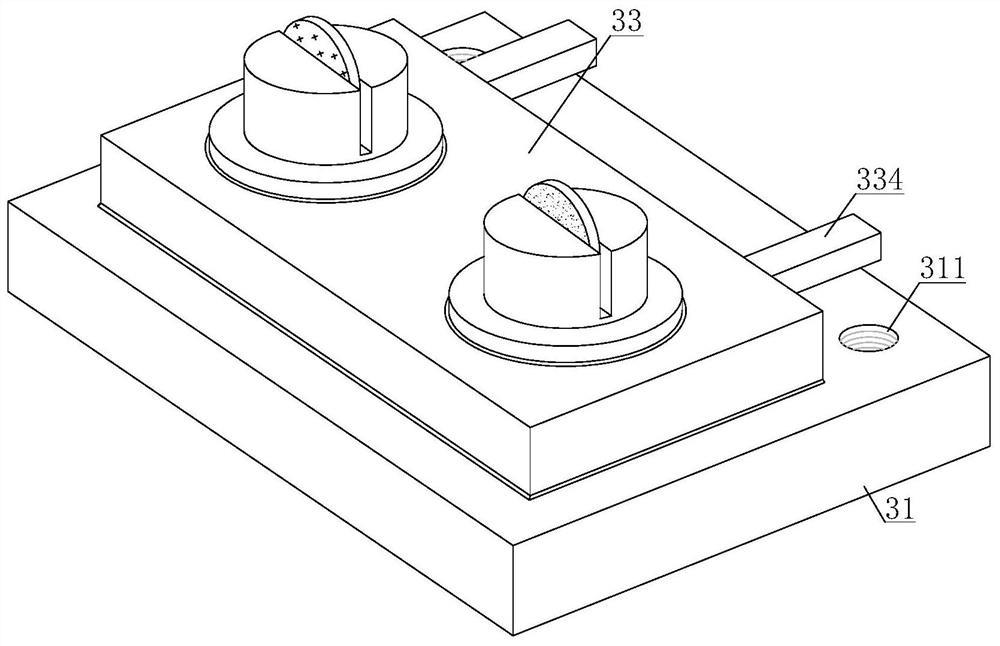

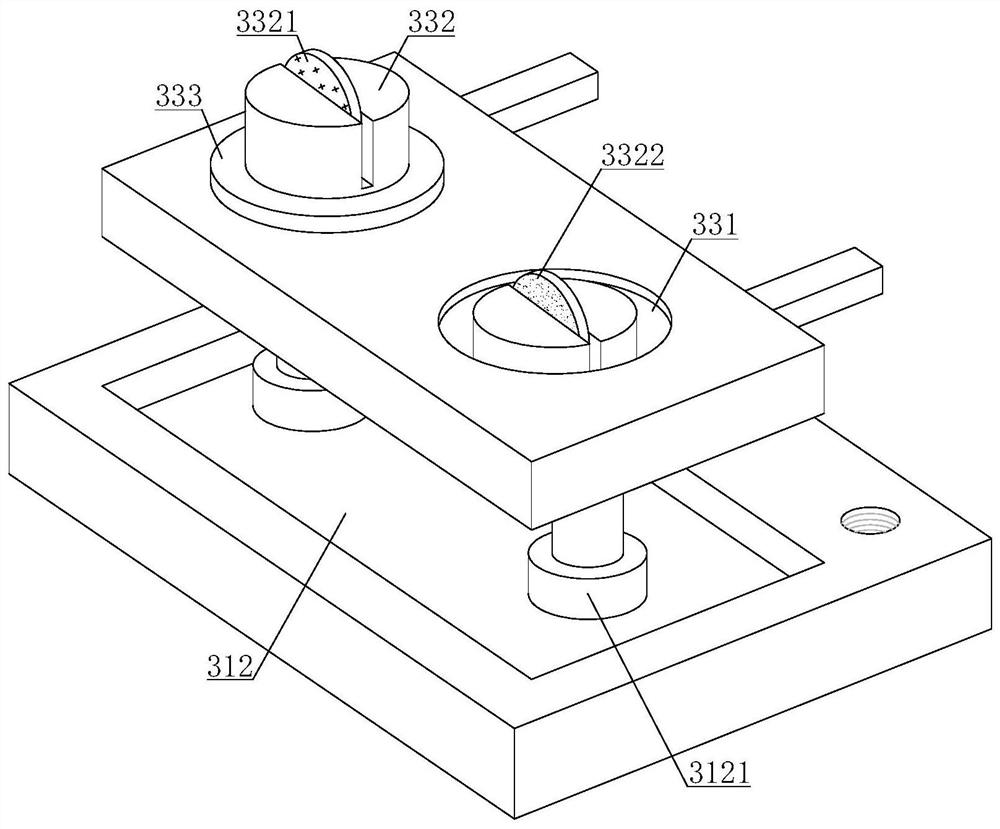

[0034] refer to figure 1 , 2 , 4, 5 and 6, a sawtooth processing device for cemented carbide saw blades, including a support mechanism 1, a connection mechanism 2 and an end body mechanism 3, one end of the connection mechanism 2 is provided with a support mechanism 1, and the other end of the connection mechanism 2 One end is provided with an end body mechanism 3, the support mechanism 1 includes a bottom box 11 and a placement plate 12, the upper end of the bottom box 11 is provided with a placement plate 12, the upper surface of the bottom box 11 is provided with a connecting mechanism 2, and the connecting mechanism 2 includes a backboard 21 , connecting bolt 22 and connecting projection 23, one end of backboard 21 is fixedly installed with connecting bolt 22, the other end of backboard 21 is fixedly installed with connecting projection 23, the upper end of backboard 21 is provided with end body mechanism 3, end body The mechanism 3 includes an end plate 31 , a hydraulic ...

Embodiment approach , 1 Embodiment approach

[0038] In order to further and better explain the above embodiments, the present invention also provides an embodiment, a method for implementing a sawtooth processing device for a cemented carbide saw blade, including the following steps:

[0039] Step 1: Connect the end plate 31 to the back plate 21 through the connecting hole 311, the back plate 21 is movably connected to the bottom box 11 through the connecting protrusion 23, and the back plate 21 is connected to the bottom box 11 through the connecting hinge 212 to complete the overall assembly ;

[0040] Step 2: Put the cemented carbide saw blade into the clamping mechanism 124, and make the sliding blocks 1242 close to each other through the telescopic rod 1241, so that the extrusion block 1243 squeezes the cemented carbide saw blade, and at the same time, the side of the extrusion block 1243 The compression washer 12431 will be deformed, so that the cemented carbide saw blade is trapped in the compression washer 12431;...

Embodiment 3

[0053] refer to figure 1 , 2 , 4, 5 and 6, a sawtooth processing device for cemented carbide saw blades, including a support mechanism 1, a connection mechanism 2 and an end body mechanism 3, one end of the connection mechanism 2 is provided with a support mechanism 1, and the other end of the connection mechanism 2 One end is provided with an end body mechanism 3, the support mechanism 1 includes a bottom box 11 and a placement plate 12, the upper end of the bottom box 11 is provided with a placement plate 12, the upper surface of the bottom box 11 is provided with a connecting mechanism 2, and the connecting mechanism 2 includes a backboard 21 , connecting bolt 22 and connecting projection 23, one end of backboard 21 is fixedly installed with connecting bolt 22, the other end of backboard 21 is fixedly installed with connecting projection 23, the upper end of backboard 21 is provided with end body mechanism 3, end body The mechanism 3 includes an end plate 31 , a hydraulic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com