Overhauling device for high-pressure oil pump of diesel engine of nuclear power station and overhauling method of overhauling device for high-pressure oil pump of diesel engine of nuclear power station

A technology of high-pressure oil pump and maintenance device, which is applied to workpiece clamping devices, manufacturing tools, etc., can solve the problems of easy damage to the cover of diesel engine, difficult installation of gaskets, and difficulty in removing gaskets. Operation, easy to carry effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] A nuclear power plant diesel engine high-pressure oil pump overhaul device and its overhaul method according to the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

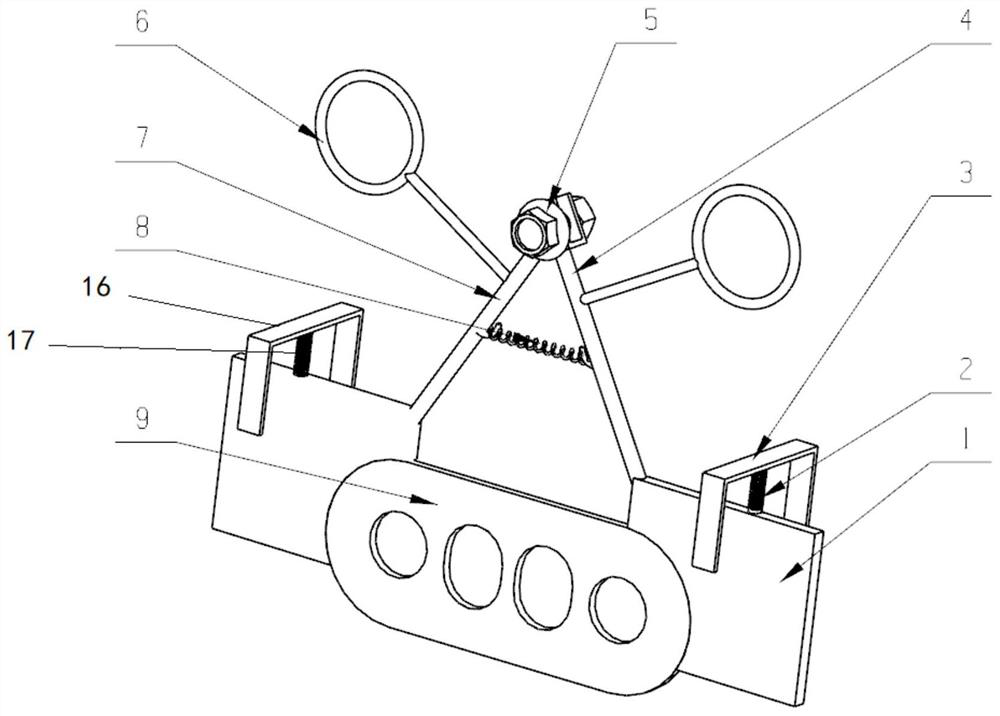

[0035] A kind of nuclear power plant diesel engine high-pressure oil pump overhaul device designed by the present invention is as follows: figure 1 As shown, it includes: left clamping part, right clamping part, gasket 9, spring B8 and bolt and nut assembly 5;

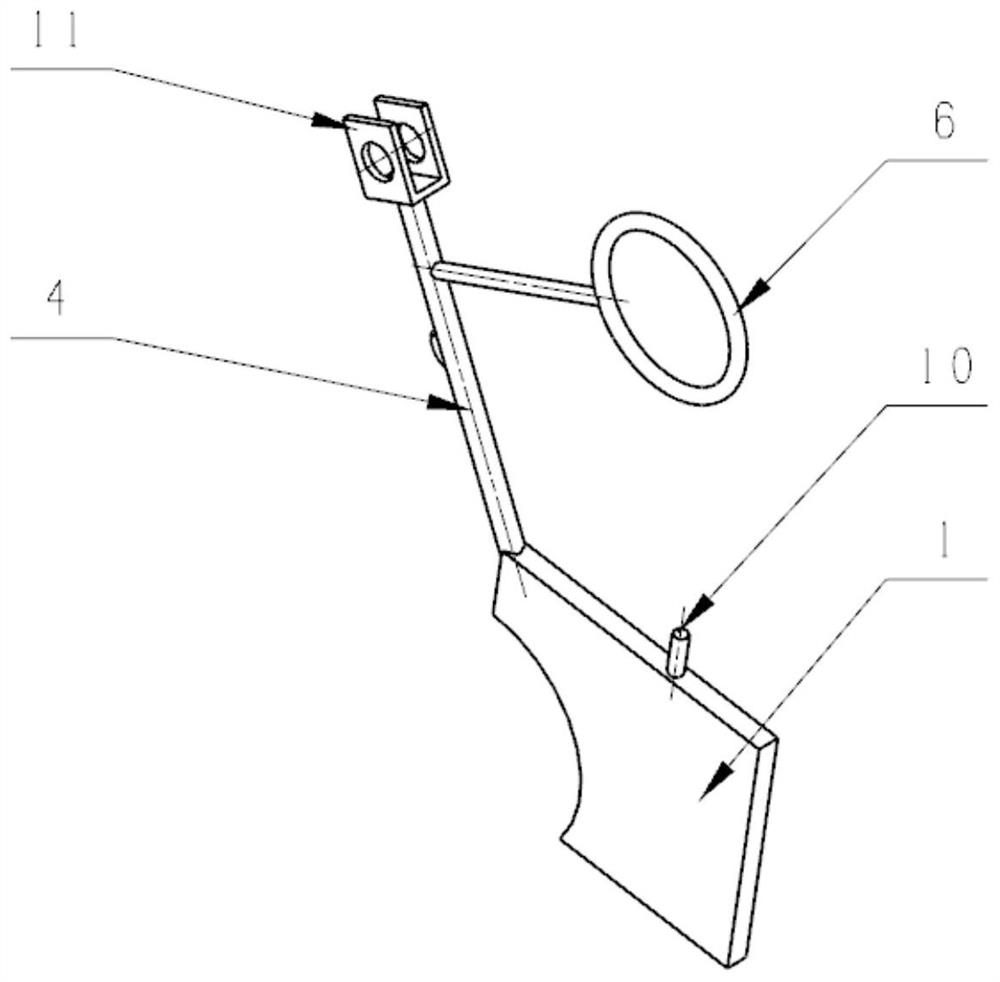

[0036] The right clamping part includes: a clamping block A1, a right clamping rod 4, a right pull ring 6 and a right fork connector 11; the clamping block A1 is welded to the right fork connector 11 There is a right clamping rod 4; a right pull ring 6 is welded on the right clamping rod 4;

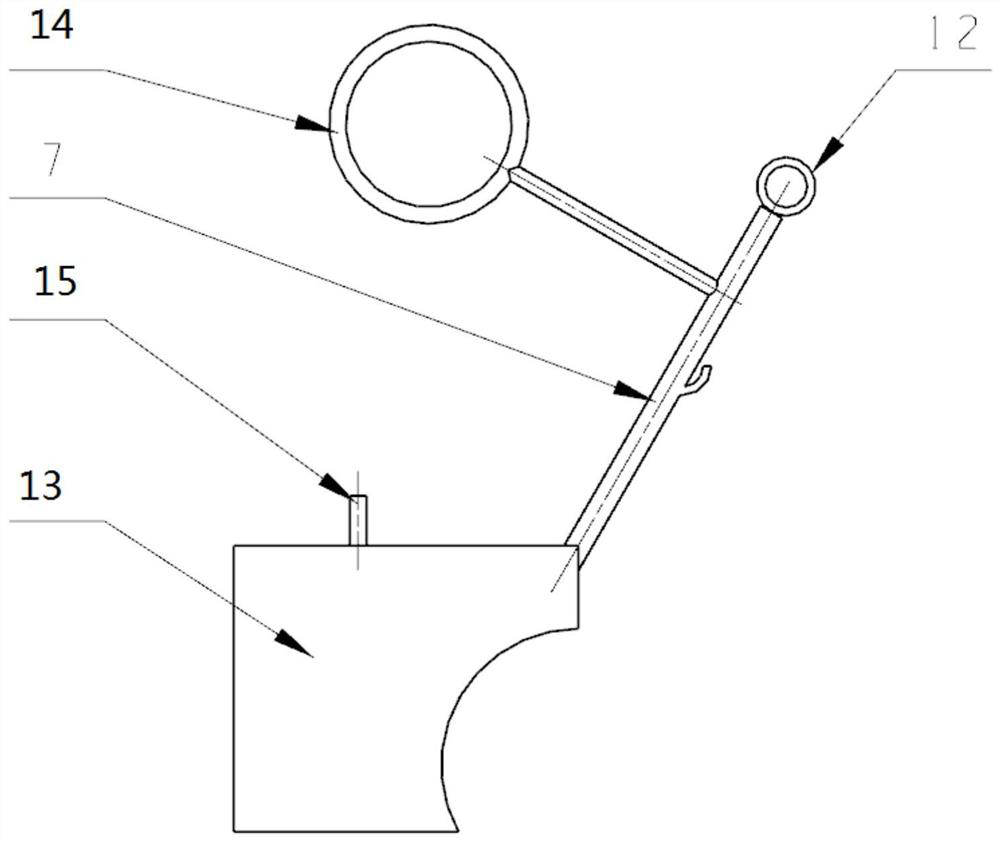

[0037] The left clamping part includes: a clamping block B13, a left clamping rod 7, a left pull ring 14 and a left connecting ring 12; a left clamp is welded between the clamping block B13 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com