Plastic empty bottle pressing and packaging production line device

A production line and plastic bottle technology, which is applied to the field of plastic empty bottle pressing and packaging production line devices, can solve the problems of labor waste, space waste, unreasonable installation and placement of equipment, etc., and achieves the effect of saving equipment investment costs and improving space use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

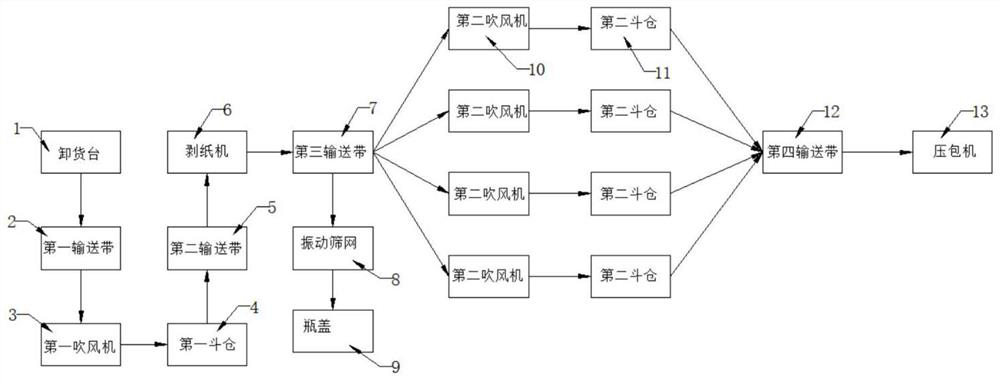

[0017] see figure 1 , the present invention provides a technical solution: plastic empty bottle pressing production line device, including an unloading table 1, the lower end of the unloading table 1 is connected with a first conveyor belt 2, and the lower end of the first conveyor belt 2 is connected with a first blower 3 , the right end of the first blower 3 is connected with a first bucket 4, the upper end of the first bucket 4 is connected with a second conveyor belt 5, and the upper end of the second conveyor 5 is connected with a stripper 6, and the stripper The right end of 6 is connected with the third conveyor belt 7, the lower end of the third conveyor belt 7 is connected with the vibrating screen 8, the lower end of the vibrating screen 8 is connected with the bottle cap 9, and the right end of the third conveyor belt 7 is connected with the Evenly arranged second blowers 10, the right end of the evenly arranged second blowers 10 is connected with a second bucket 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com