A physically catalyzed liquid mixing impeller

A technology of liquid mixing and impeller, which is applied in the direction of fluid mixers, mixers, chemical instruments and methods, etc., can solve the problems of little effect on energy saving and emission reduction, labor cost burden, hidden safety hazards, etc., and achieve novel technology and increase Loss, the effect of improving combustion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

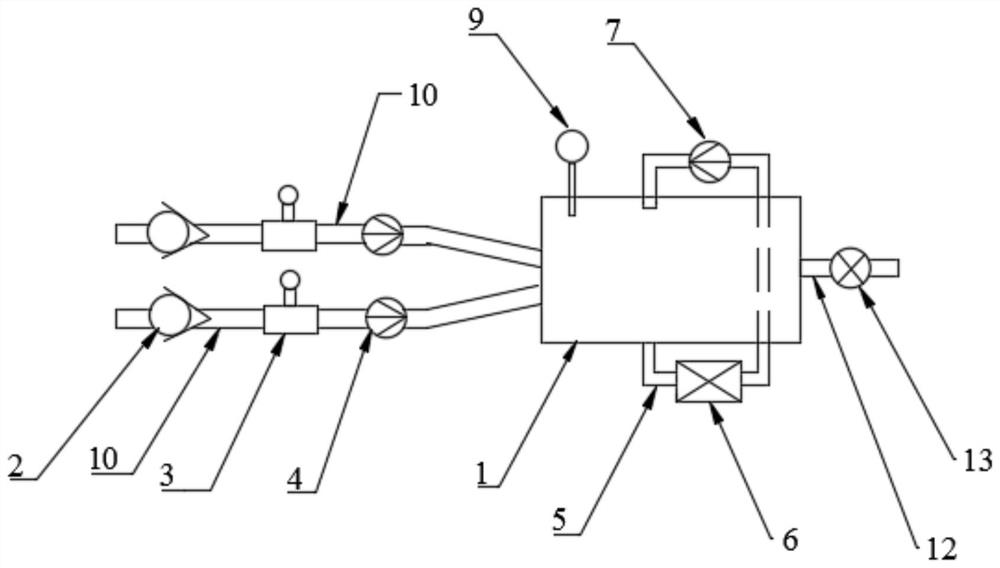

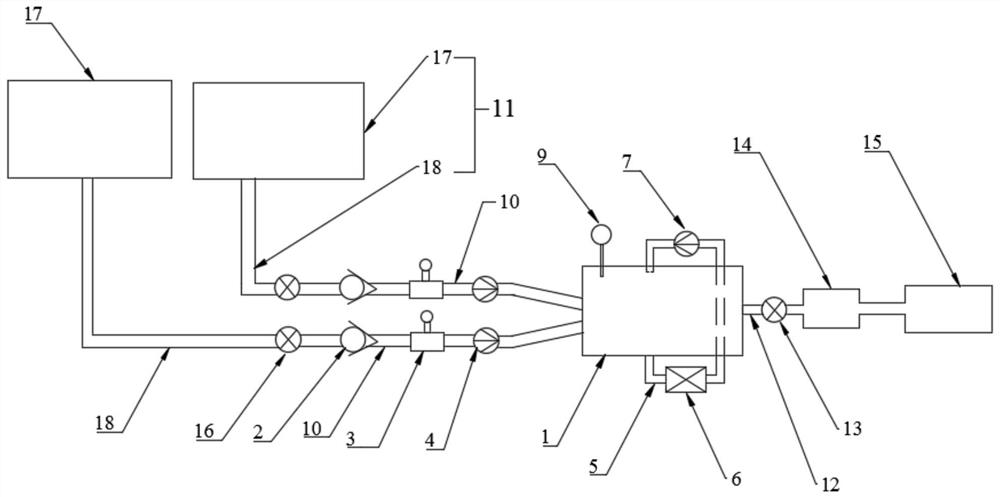

[0031] see Figures 1 to 2 , a physical catalytic liquid mixing propeller, comprising a mixing container 1, one side wall of the mixing container 1 is connected with a plurality of feed pipes 10, in this embodiment, the number of the feed pipes 10 is two One, the other side wall is connected to the burner input pipe 12, the burner input pipe 12 is provided with a first valve 13, and the burner input pipe 12 is used to communicate with the burner 14; One end is used for corresponding connection with a raw material output end 11, the raw material output end 11 includes a raw material storage tank 17 and an output pipeline 18, the output pipeline 18 is provided with a second valve 16, and the raw material output end 11 is used for outputting raw materials; The other end of the pipeline 10 is connected with the mixing container 1; each feeding pipeline 10 is provided with a one-way solenoid valve 2, a flow meter 3 and a first conveying pump 4 in turn; the mixing container 1 is con...

Embodiment 2

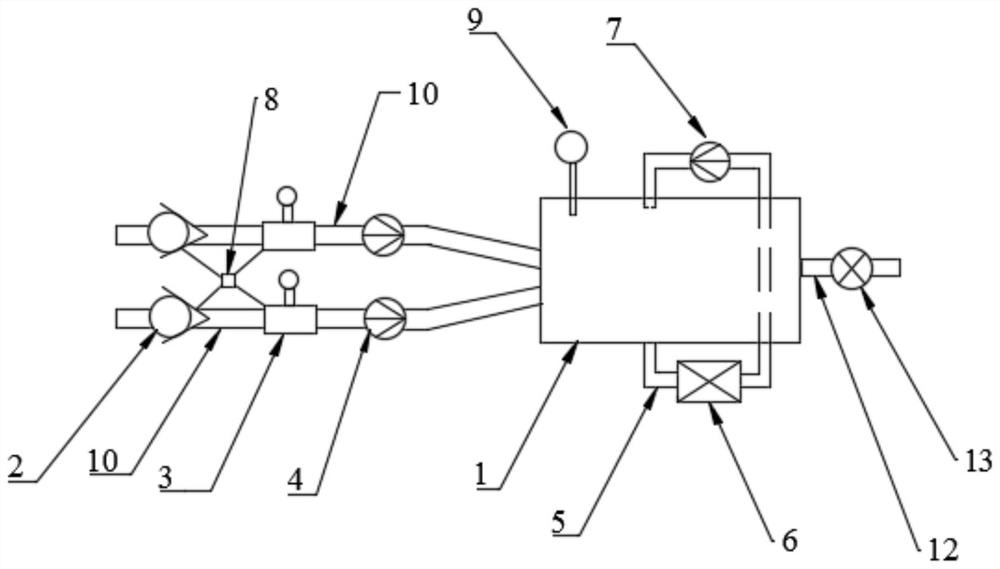

[0035] like Figures 3 to 4 As shown, the difference between this embodiment and Embodiment 1 is that the flow meter 3 is an electronic flow meter 3, and the pusher further includes a PLC controller 8, which is respectively connected with the one-way solenoid valve 2 and the one-way solenoid valve 2 and The electronic flow meter 3 is connected. When in use, the PLC controller 8 presets the target raw material value. When the electronic flow meter 3 detects that the flow reaches the target raw material value, it transmits a signal to the PLC controller 8, and the PLC controller 8 controls the one-way electromagnetic Valve 2 is closed, and the delivery of raw materials is automatically stopped to achieve precise target burning of raw materials.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com