A kind of corrugated cardboard and corrugated box production process

A corrugated cardboard and corrugated box technology, which is applied in paper/cardboard layered products, paper/cardboard containers, papermaking, etc., can solve the problems of poor flame retardancy of corrugated cardboard and limit the application of corrugated boxes, and reduce the risk of burnout Risk, the effect of improving the flame retardant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

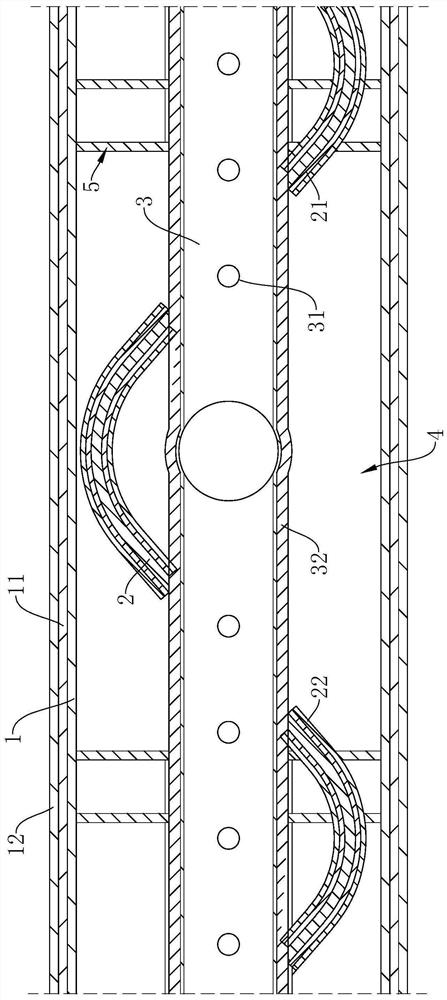

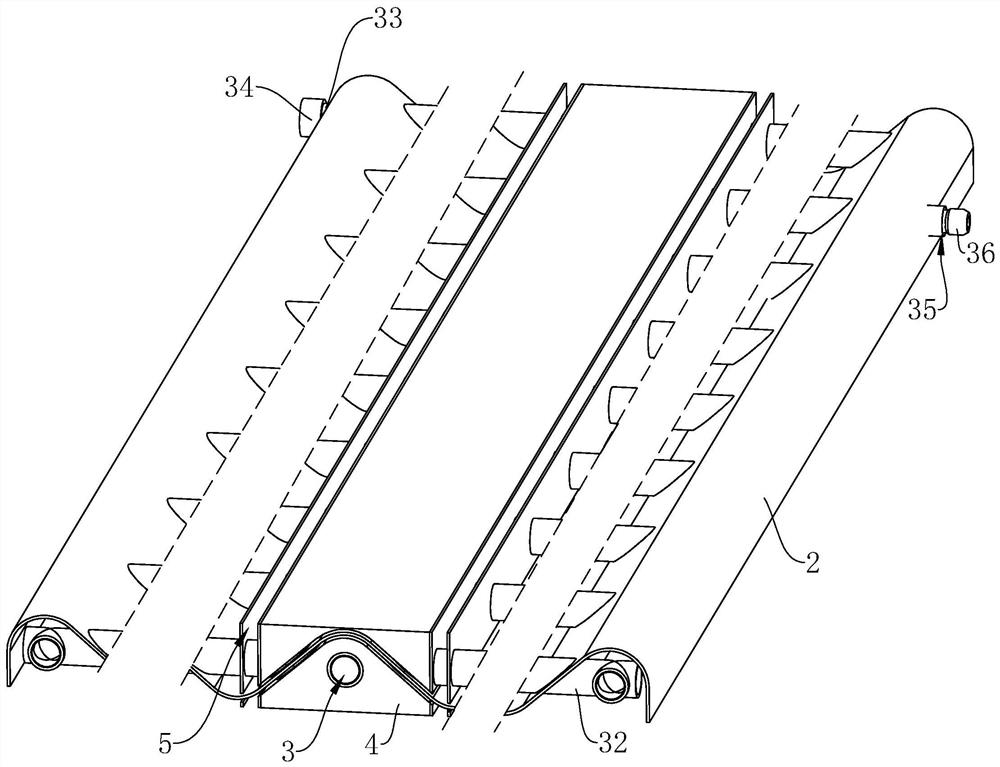

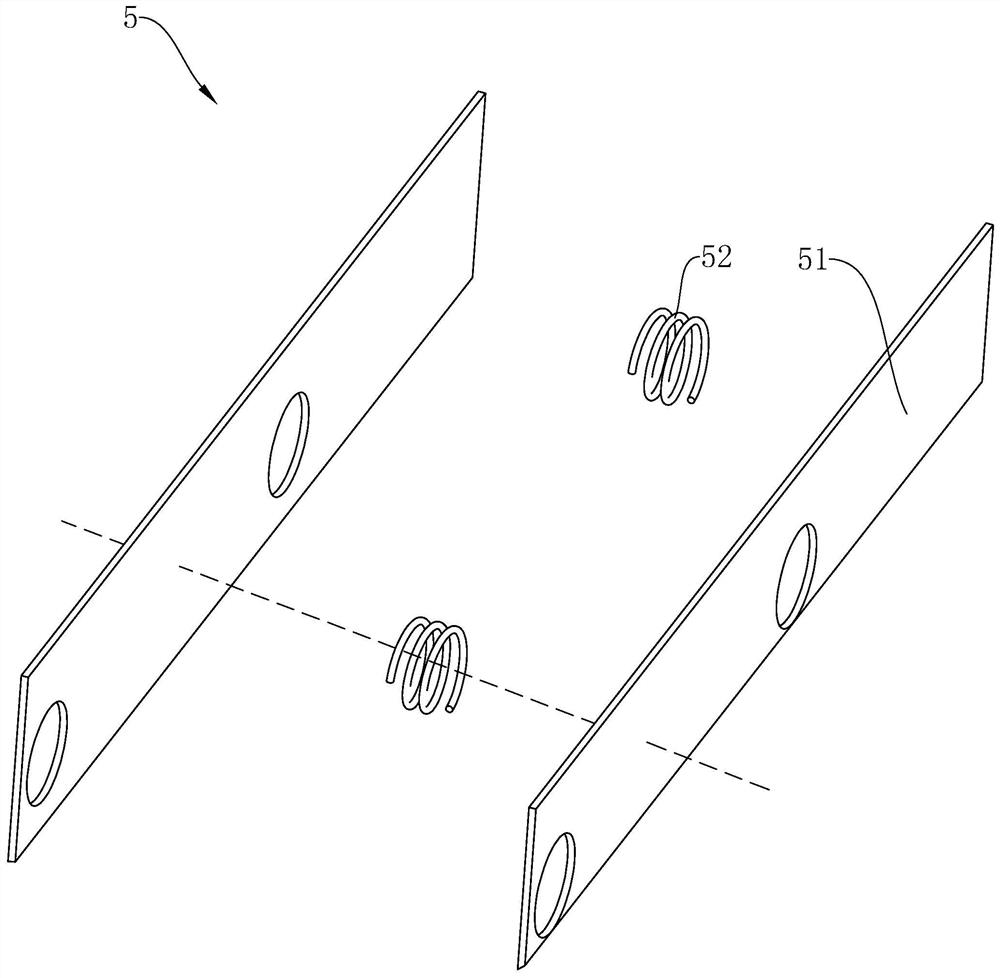

[0041] Attached to the following Figure 1-3 This application will be described in further detail.

[0042] The embodiment of the present application discloses a corrugated cardboard, refer to figure 1 and figure 2, the corrugated cardboard includes corrugated core paper 2 and two outer layers of cardboard 1, the corrugated core paper 2 is wavy, the corrugated core paper 2 is located between the two outer layers of cardboard 1, and the peaks and troughs of the corrugated core paper 2 are respectively related to the outer layers of the two layers. The layers of cardboard 1 are fixedly connected, and a flexible grid-shaped soft water pipe 3 is arranged between the two outer layers of cardboard 1. The soft water pipe 3 runs through the corrugated core paper 2, and the circumferential side wall of the soft water pipe 3 is provided with a plurality of equal distances. Distributed water outlet holes 31, the soft water pipe 3 is filled with fire extinguishing liquid, the outer wal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com