Copper foil roll vacuum storage box facilitating batched taking and placing

A technology for vacuum storage and copper foil rolls, applied in packaging under vacuum/special atmosphere, containers to prevent mechanical damage, packaging objects under special gas conditions, etc., can solve problems such as copper foil roll oxidation and affect product quality, and achieve The effect of reducing losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

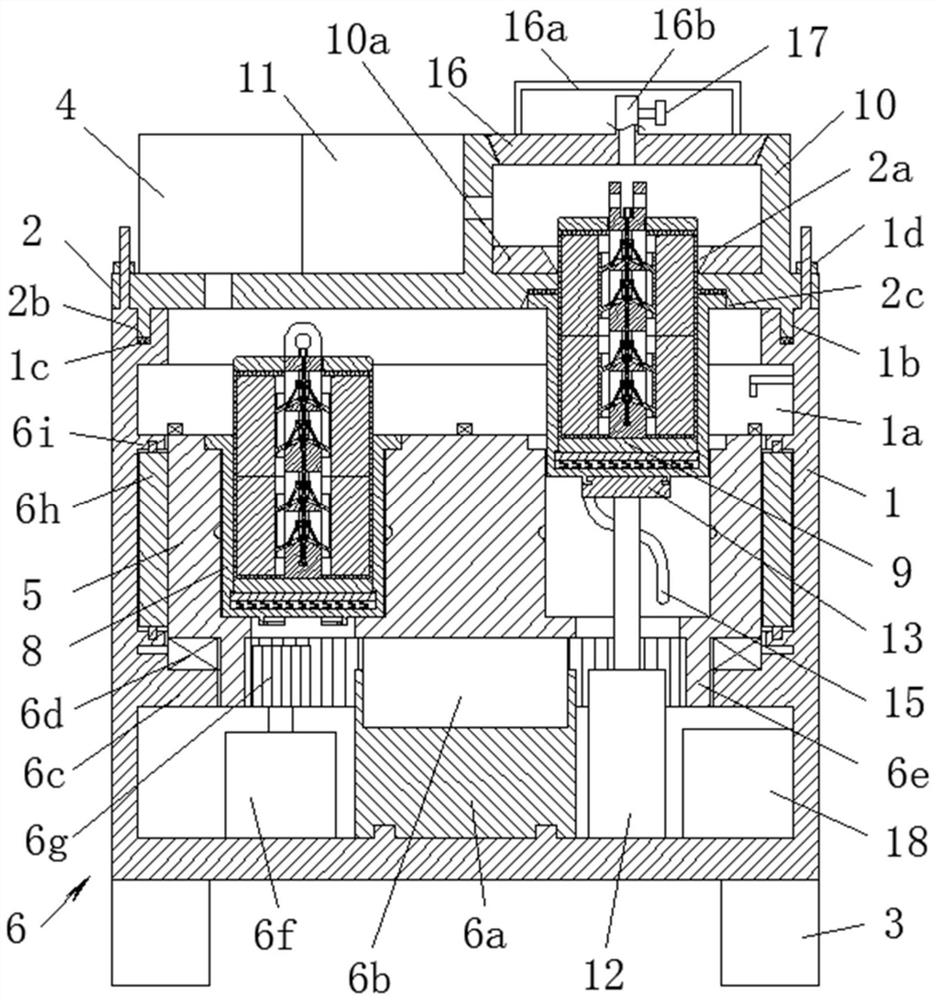

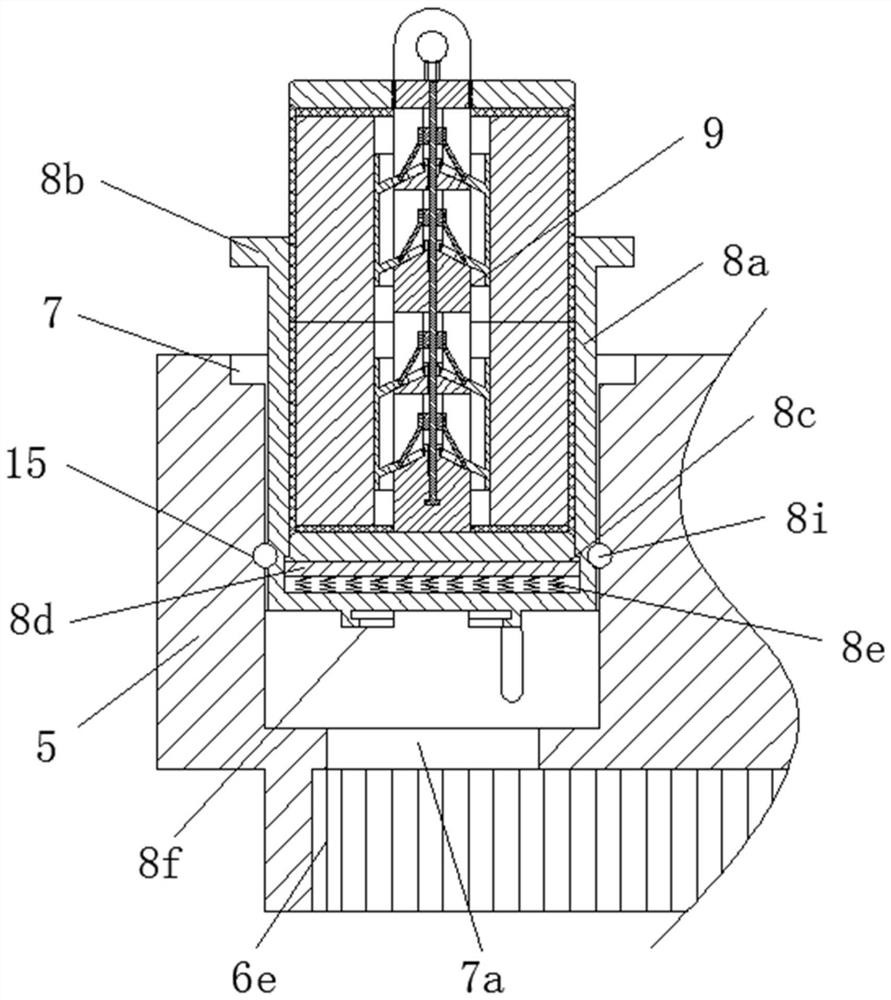

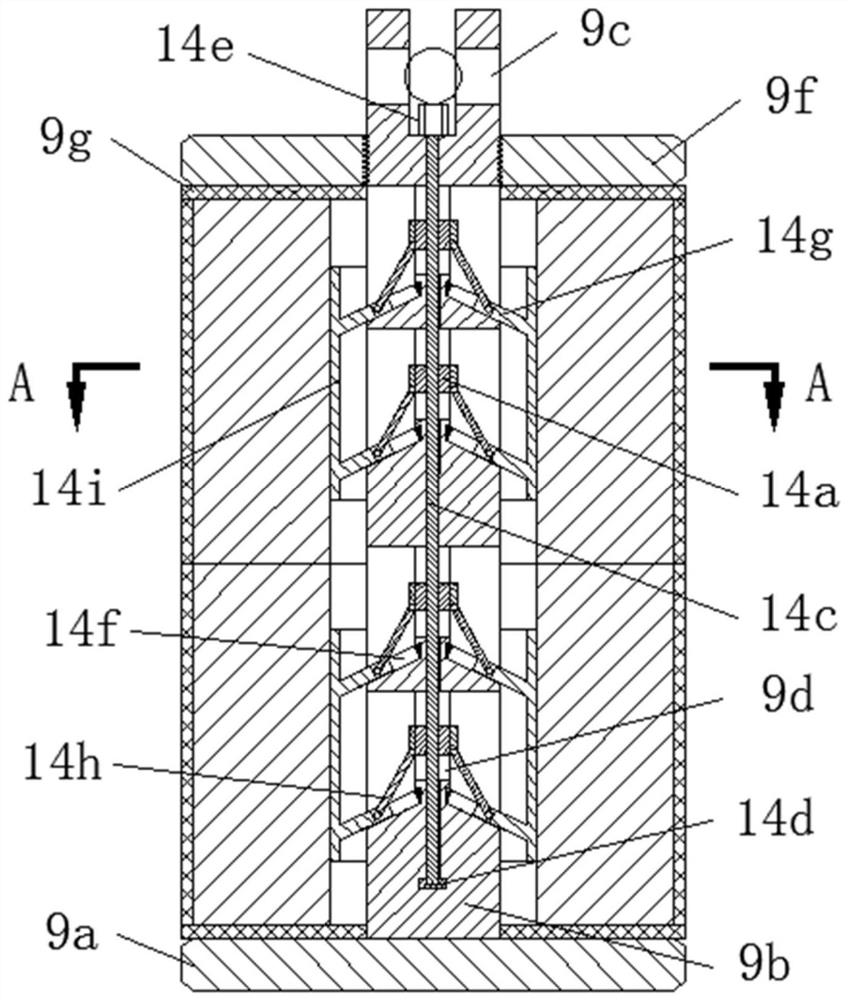

[0038] refer to Figure 1 to Figure 8 As shown, a vacuum storage box for copper foil rolls that is convenient to be taken and placed in batches according to the present invention includes a box body 1 and a box cover 2 detachably connected to the top of the box body 1, and a support 3 is provided at the bottom of the box body 1. The box body 1 and the box cover 2 cooperate to form a vacuum placement chamber 1a, and the vacuum placement chamber 1a is conductively connected with a first vacuum pump 4; a rotating placement disk 5 is arranged in the vacuum placement chamber 1a; The corresponding box body 1 is provided with a rotary drive mechanism 6 connected to the rotating placing tray 5; on the rotating placing tray 5, a number of placing grooves 7 are distributed at intervals along the circumferential direction, and in the placing grooves 7 are provided with copper foil coils. The sealed storage bucket 8 is provided with a copper foil roll fixing frame 9 for fixing the copper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com