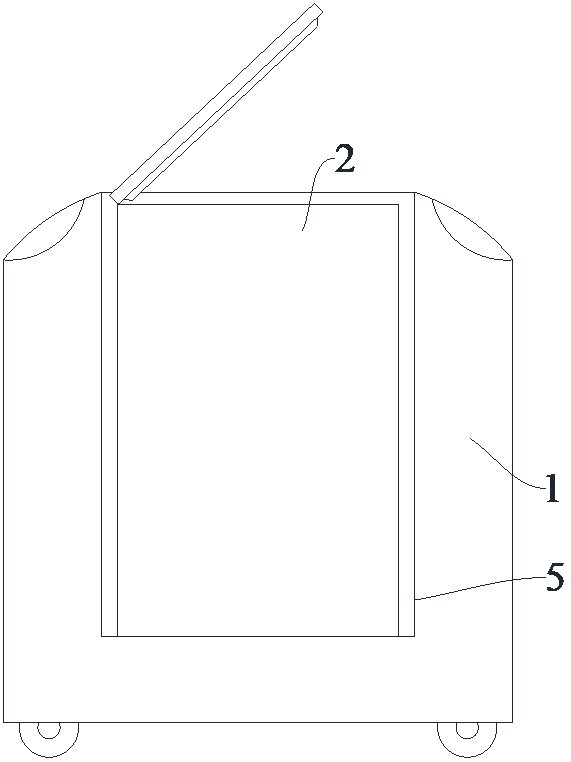

Medical auxiliary material conveying and recycling device with quick release mechanism

A recovery device and auxiliary material technology, which is applied in the field of medical auxiliary material delivery and recovery devices with a quick-release mechanism, can solve the problems of unable to squeeze medical auxiliary materials, affect the work of medical staff, increase medical costs, etc., and achieve convenient transmission and connection Separate from disassembly, convenient for multi-layer extrusion storage, and improve the effect of transmission safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

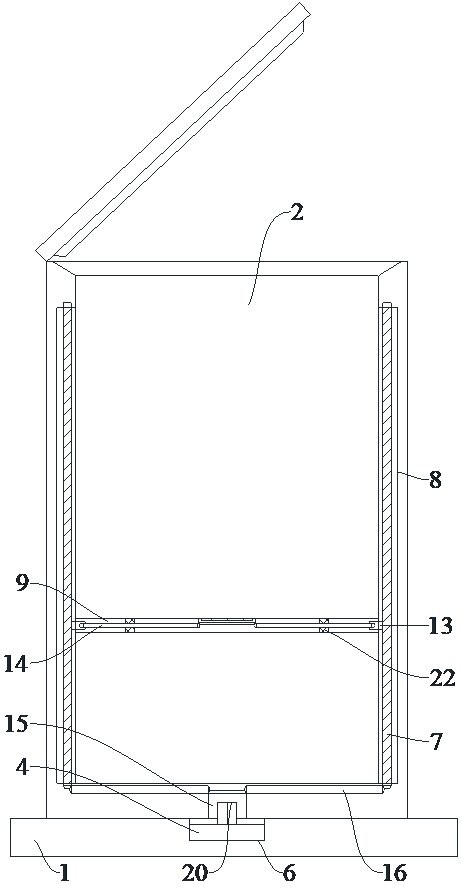

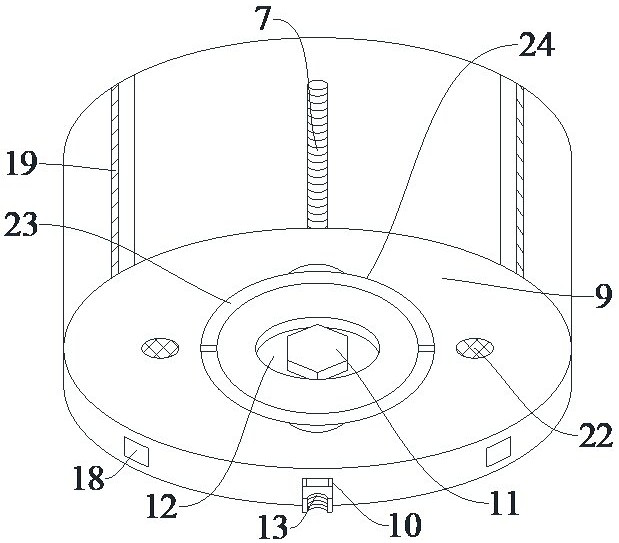

[0036] Embodiment 1: The internal thread telescopic block 13 adopts an arc-shaped extrusion assembly groove sleeve on the outer wall of the longitudinal adjustment screw 7 and engages with the outer wall of the longitudinal adjustment screw 7;

Embodiment 2

[0037] Embodiment 2: It is also possible to set an insert block on the outer top of the inner thread telescopic block 13, and then thread the lifting sleeve on the outside of the longitudinal adjustment screw 7, and assemble it by inserting the insert block into the slot on the outer surface of the lift sleeve.

[0038] Further, in order to cooperate with the electromagnet 3 to control expansion and contraction, a lateral telescopic groove for installing the electromagnet 3 is provided on the outer surface of the internal partition extrusion plate 9, and the outer surface of the electromagnet 3 is located inside the lateral telescopic groove and is elastically stretched by the iron spring 17. A lateral locking block 18 is connected, and a vertical guide groove 19 with a built-in locking surface is provided on the inner surface of the storage tube 2 corresponding to the position of the lateral locking block 18 .

[0039]An electromagnet 3 is also installed on the internally thre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com