Composition, polymer for capacitor and capacitor

A composition and capacitor technology, applied in the direction of capacitors, capacitor electrolytes/absorbents, electrolytic capacitors, etc., can solve problems such as increased leakage current and decreased withstand voltage, and achieve the goals of preventing corrosion, reducing oxide film damage, and slowing down polymerization speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] This embodiment is used to illustrate a method for preparing a composition, a capacitor polymer and a capacitor disclosed in the present invention, including the following steps:

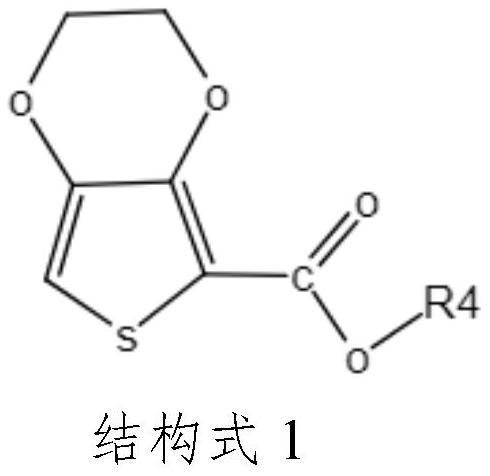

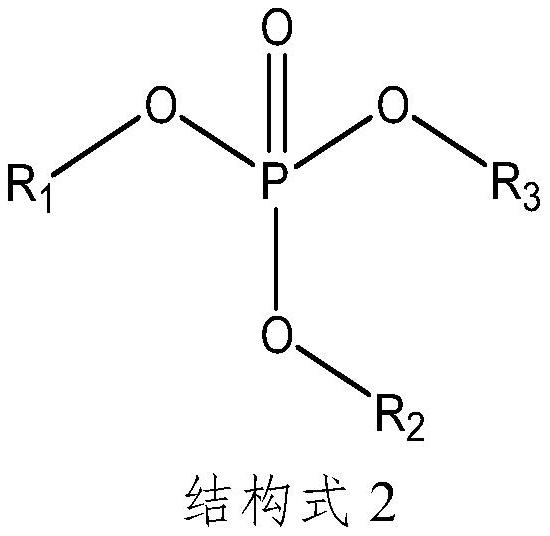

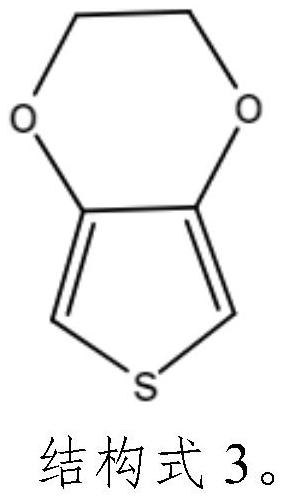

[0056] With 0.07% by weight of tributyl phosphate, 0.01% by weight of 3,4-ethylenedioxythiophene-2-methyl carboxylate, and 99.92% by weight of 3,4-ethylenedioxythiophene, the above three substances Mix well to prepare a composition containing polymerized monomers, phosphoric acid ester compounds and end-capping agents.

[0057] The above composition is used as a polymerization raw material to prepare an aqueous polymer dispersion by free radical polymerization. The specific implementation process is: get 1753g water and 90.32g sodium polystyrene sulfonate, mix them uniformly at high speed in the disperser, under the protection of nitrogen atmosphere, control the temperature in the reactor to be 22°C, add 17.54g ferric sulfate aqueous solution (1.3 % concentration) and 7.25g of the above-ment...

Embodiment 2

[0060] This example is used to illustrate a composition disclosed by the present invention, a capacitor polymer and a method for preparing a capacitor, including most of the operating steps in Example 1, the difference being:

[0061] The above-mentioned The three substances are mixed evenly to prepare a composition containing polymerized monomers, phosphoric acid ester compounds and end-capping agents.

Embodiment 3

[0063] This example is used to illustrate a composition disclosed by the present invention, a capacitor polymer and a method for preparing a capacitor, including most of the operating steps in Example 1, the difference being:

[0064] The above-mentioned The three substances are mixed evenly to prepare a composition containing polymerized monomers, phosphoric acid ester compounds and end-capping agents.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com