High-performance modified asphalt and preparation method thereof

A modified asphalt, high-performance technology, used in building components, building insulation materials, buildings, etc., can solve the problems of incompatibility, single modification effect, side effects, etc., to reduce the difficulty of modification, slow down delamination and The speed of segregation, the effect of reducing the risk of early cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-18

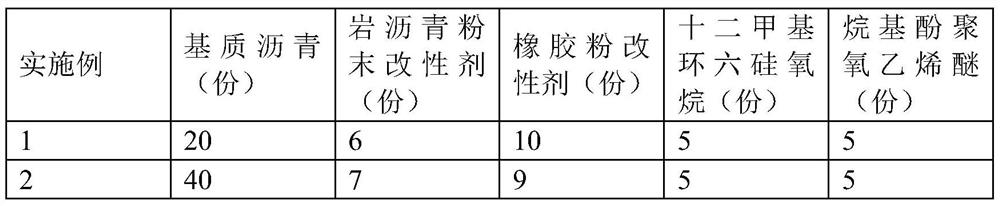

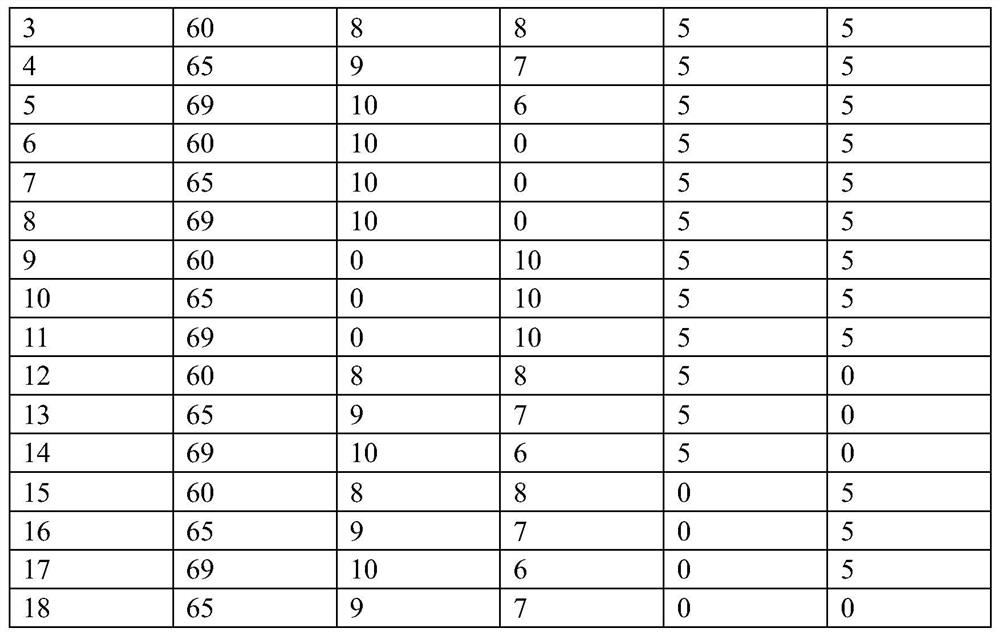

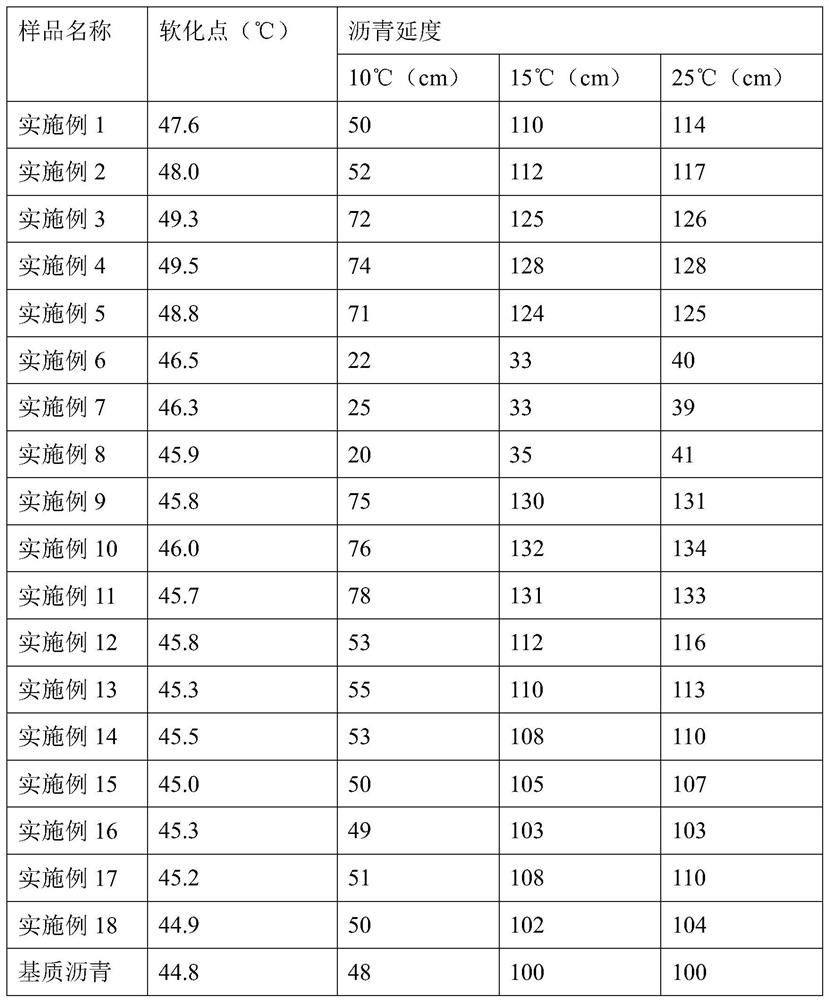

[0046] Examples 1-18, a high performance modified asphalt, its components and their corresponding quality as shown in Table 1, and is prepared by the following steps.

[0047] S1: Natural modification: The matrix asphalt is heated to 150 ° C, and the rock asphalt powder modifier is added while stirring, then continues to heat up to 180 ° C, stirring with a normal high-speed high-speed mixer of 4000 rpm to obtain a rocky selection asphalt;

[0048] S2: Add octylphenol polyoxyethylene ether to the rocky seamant, stirred for 15 min to obtain a rocky-modified asphalt dispersion;

[0049] S3: The temperature of the rock asphalt modified asphalt dispersion is adjusted to 180 ° C, and the rubber powder modifier is added to the dispersion, and the dimethylcycithcytic cyclic silicone is added, and the shearing machine is opened to obtain a mixed modified asphalt. ;

[0050] S4: Place the mixed modified asphalt to a temperature of 180 ° C for 1 h;

[0051] S5: Add a shrinkage agent to the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com