Method for improving dust collection efficiency of electrostatic dust collector of converter

An electrostatic precipitator and efficiency technology, which is applied in the field of improving the dust removal efficiency of an electrostatic precipitator for converter dry dust removal, can solve problems such as inability to distribute evenly, and achieve the effects of avoiding high dust removal pressure, improving efficiency, and reducing smoke generation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0024] A kind of method of improving dust removal efficiency of converter electrostatic precipitator described in the present invention comprises:

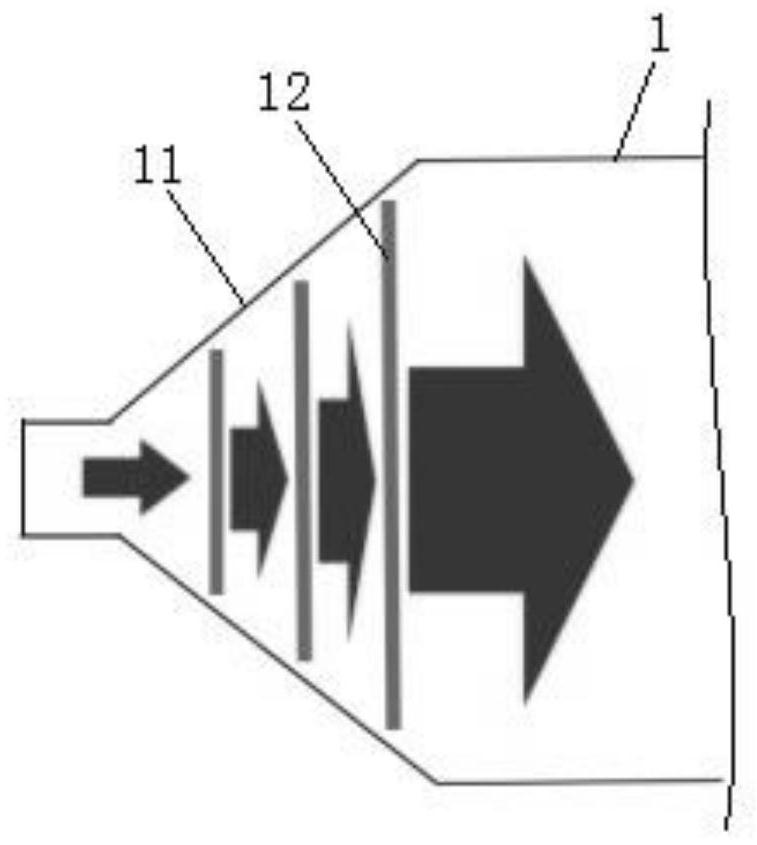

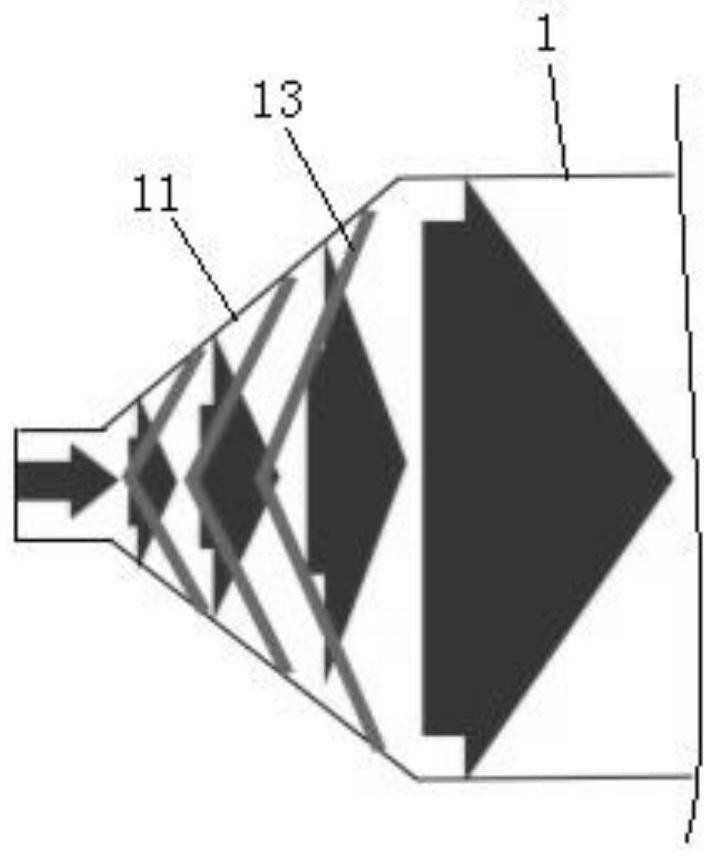

[0025] 1) Structural improvement of the inlet flue gas distribution plate of the electrostatic precipitator;

[0026] a, a plurality of flue gas distribution plates 12 located at the enlarged diameter section 11 at the flue gas inlet of the electrostatic precipitator 1 adopt conical flue gas distribution plates 13 (such as figure 2 As shown), the large end of the conical flue gas distribution plate 13 is facing the inside of the electrostatic precipitator 1, and is fixedly connected with the cylinder wall of the enlarged diameter section 11;

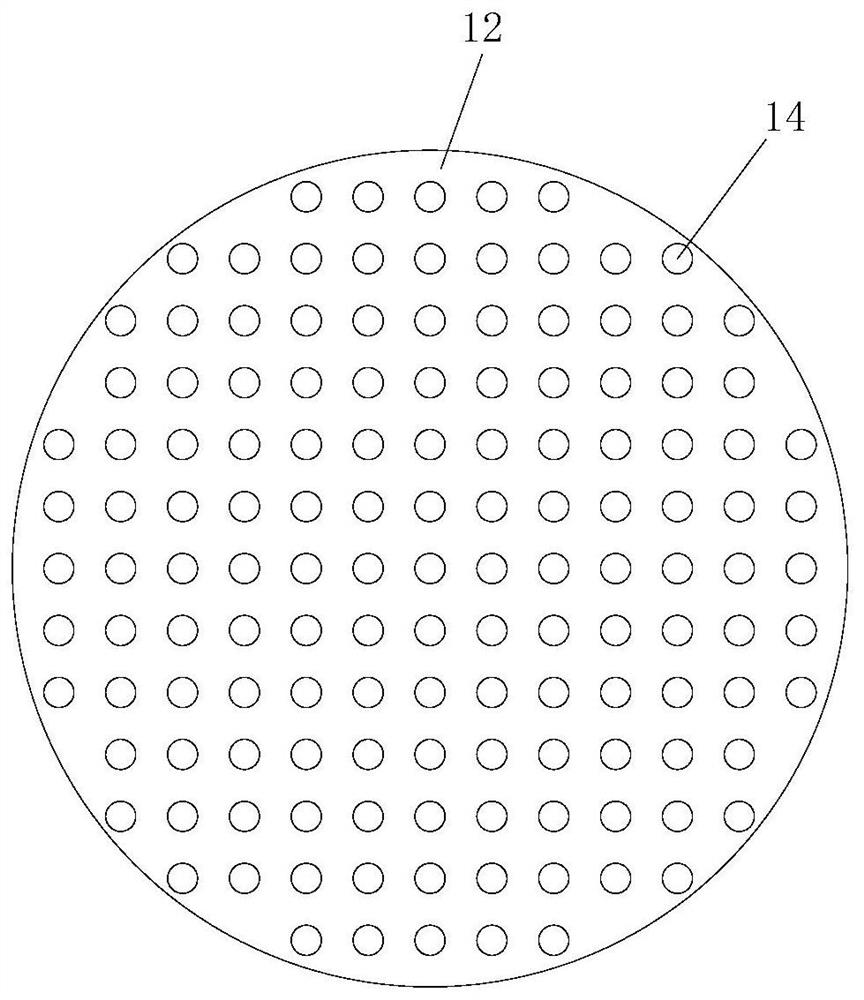

[0027] b, the opening ratio of the smoke guide hole 14 on the conical smoke distribution plate 13 gradually increases from the center to the periphery (such a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com