A screen-type liquid acquisition device for cryogenic propellant on-orbit management

A low-temperature propellant and acquisition device technology, used in jet propulsion devices, rocket engine devices, machines/engines, etc. problems, to achieve the effect of resisting the risk of bubble burst failure, improving the liquid acquisition rate, and improving the liquid acquisition rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

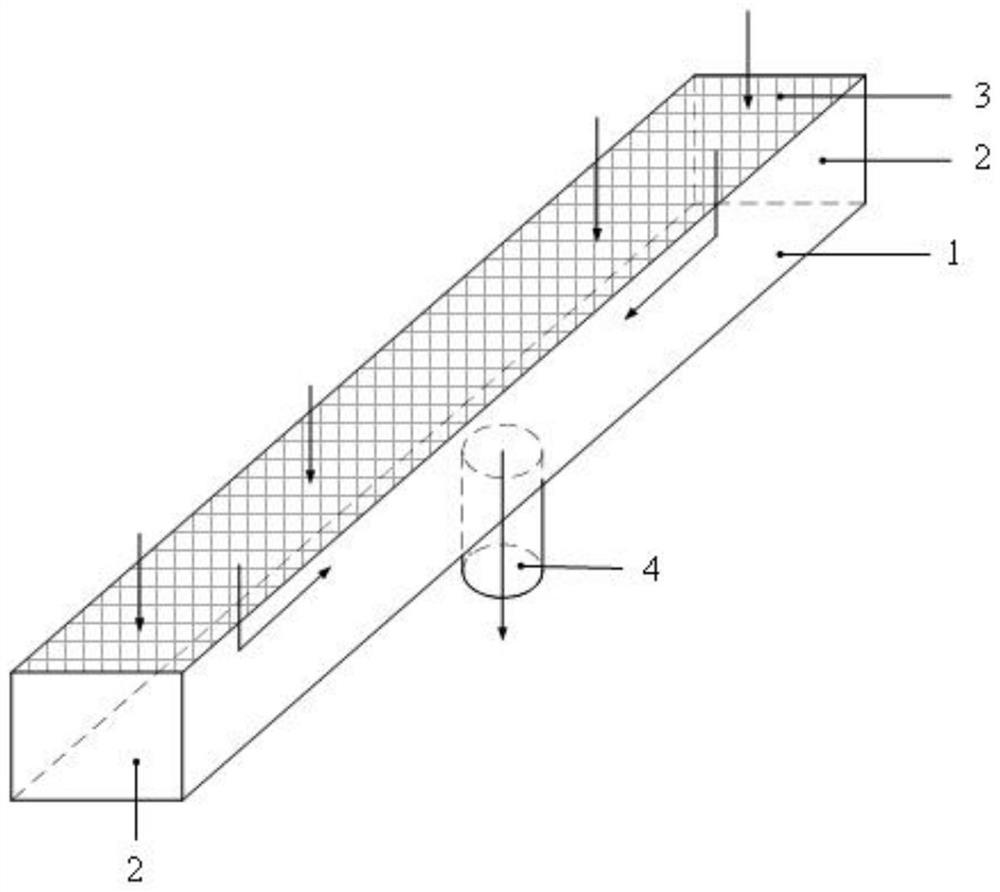

[0022] Embodiment 1: as figure 1 As shown, a screen-type liquid acquisition device for low-temperature propellant on-orbit management includes a hollow channel surrounded by metal walls 1 on three sides and a metal screen 3 on one side. Both ends of the channel are blinded. The end 2 is blocked to form a closed cavity; the center of the metal wall 1 facing the metal mesh curtain 3 is provided with a channel outlet 4, and the arrows in the figure indicate the flow direction of the liquid.

[0023] The working principle of Embodiment 1: Research shows that the total liquid extraction rate of the channel increases with the decrease of the ratio of channel length to depth (length-to-depth ratio). Setting the outlet 4 of the channel in the middle of the channel is equivalent to dividing a long channel into two short sub-channels. The depth of each sub-channel is constant and the length is halved, so the aspect ratio is also halved accordingly, that is, the length of the entire chan...

Embodiment 2

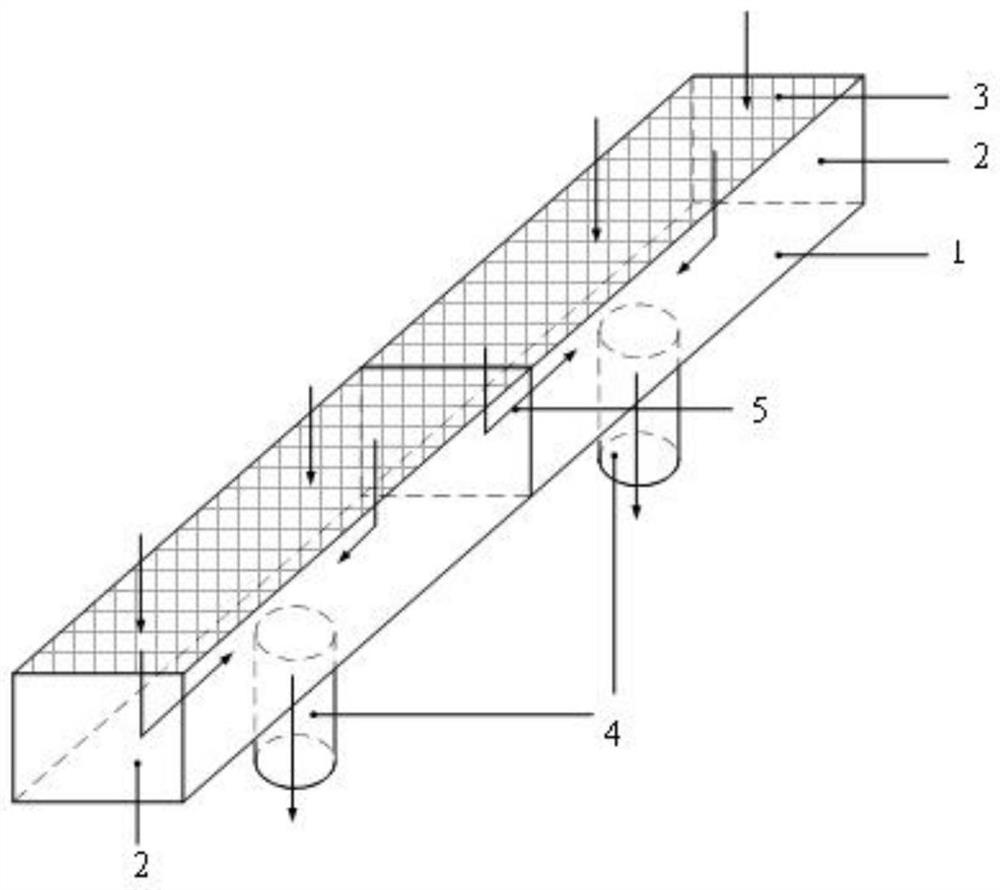

[0024] Embodiment 2: as figure 2 As shown, a screen-type liquid acquisition device for low-temperature propellant on-orbit management includes a hollow channel surrounded by metal walls 1 on three sides and a metal screen 3 on one side. Both ends of the channel are blinded. The end 2 is blocked to form a closed cavity, and the inside of the cavity is divided into two sub-cavities that are not connected to each other through the partition plate 5; the center of the metal wall 1 facing the metal mesh curtain 3 of each sub-cavity A channel outlet 4 is provided, and the arrows in the figure indicate the flow direction of the liquid.

[0025] The working principle of embodiment 2: the total liquid extraction rate of the channel increases with the decrease of the length-depth ratio of the channel. When the liquid acquisition device is used for a particularly large storage tank, its length is also particularly large. At this time, it can be introduced by introducing The partition p...

Embodiment 3

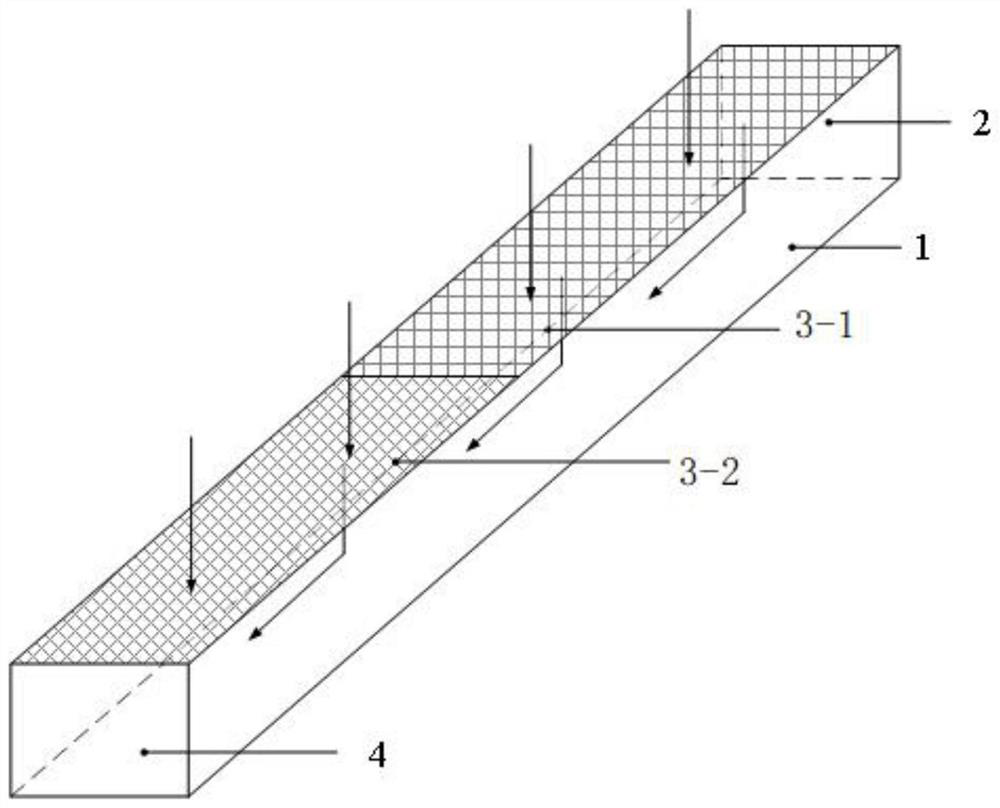

[0026] Embodiment 3: as image 3 As shown, a screen-type liquid acquisition device for low-temperature propellant on-orbit management includes a hollow channel surrounded by metal walls 1 on three sides and a metal screen on one side, and the upstream end of the channel is bounded by a blind end 2 Blocking, the metal mesh curtain in the upstream section of the channel adopts a coarse mesh screen 3-1; the downstream end of the channel is a channel outlet 4, and the metal mesh curtain in the downstream section of the channel adopts a fine mesh screen 3-2, thereby forming a closed The cavity; the transition between the coarse-mesh screen 3-1 and the fine-mesh screen 3-2 is through welding or bonding, and the arrows in the figure indicate the flow direction of the liquid.

[0027] The working principle of embodiment 3: the metal mesh screen has two important parameters, namely the pressure difference of bubble breaking (being the maximum pressure difference that the liquid film bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com