Automatic pretreatment system and pretreatment method for food detection sample

A food testing and pretreatment technology, which is applied in the preparation, sampling, and measuring devices of test samples, can solve the problems of time-consuming and labor-intensive work, increase the labor intensity of testing personnel, etc., achieve accurate detection, and promote the effect of shaking operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

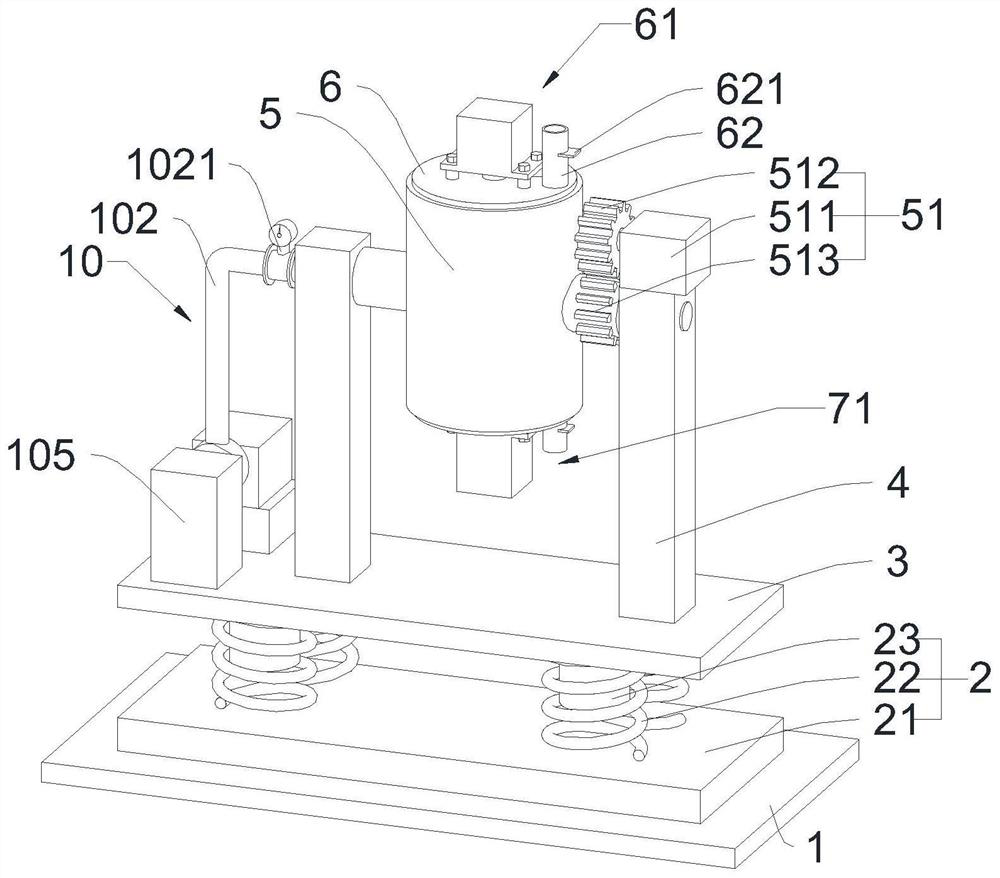

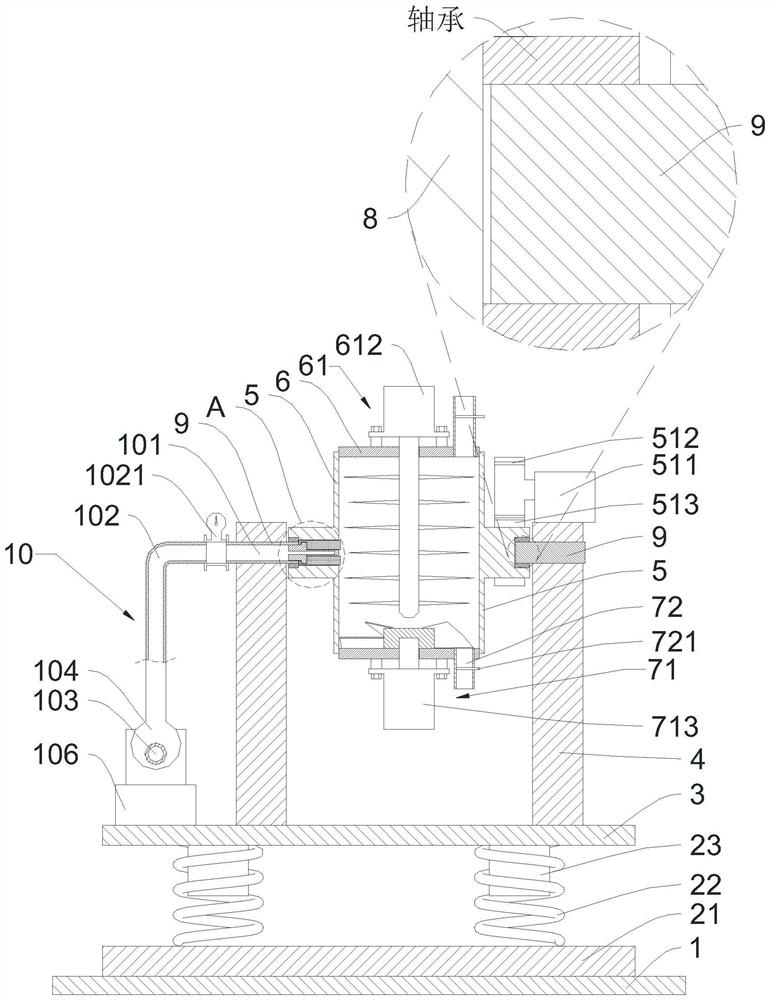

[0032] The following is attached Figure 1-6 The present invention is described in further detail.

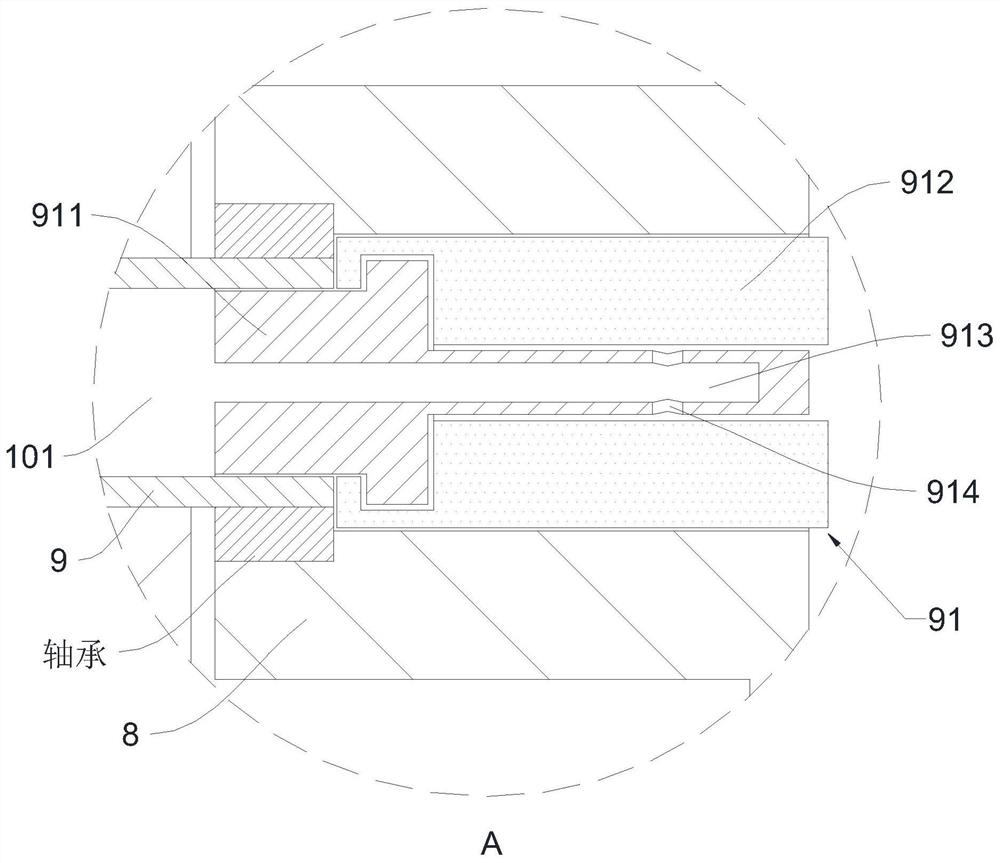

[0033] An automatic pretreatment system for food testing samples of the present invention includes a working platform 1 for support, a shaking mechanism 2 and a mounting plate 3 are sequentially arranged above the working platform 1, and the mounting plate 3 is symmetrically provided with an upwardly extending mounting column 4, A working cylinder 5 is arranged between the two installation columns 4, and the upper and lower ends of the working cylinder 5 are respectively threaded with an upper sealing disk 6 and a lower sealing disk 7. The sealing disc 7 is located below the upper sealing disc 6, and the working cylinder 5 is provided with an extension column 8 near the side of the installation column 4, and the extension column 8 is integrally formed with the work cylinder 5, and the extension column 8 is rotated to be provided with an installation shaft 9, and The installati...

Embodiment 2

[0041] On the basis of Embodiment 1, the difference is that the crushing blade 613 is composed of a blade body 6131 and a blade blade 6132. The crushing blade 613 is provided with several along the circumference of the crushing shaft 611, and the blade body 6131 and the crushing shaft 611 are welded. Fixedly connected, the blade blade 6132 is a fan-shaped structure, and the blade blade 6132 is welded to the edge of the blade body 6131 by welding to cut and pulverize the food sample put into the working cylinder 5 . During specific work, when the food sample is crushed, the blade blade 6132 continuously cuts and pulverizes the food sample; effect, thereby accelerating the dissolution of food samples in water.

[0042] In addition, the present invention also provides a pretreatment method of an automatic pretreatment system for food testing samples, the steps of which are as follows:

[0043] S1, feeding: open the feeding valve 621, put the food sample to be pulverized into the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com