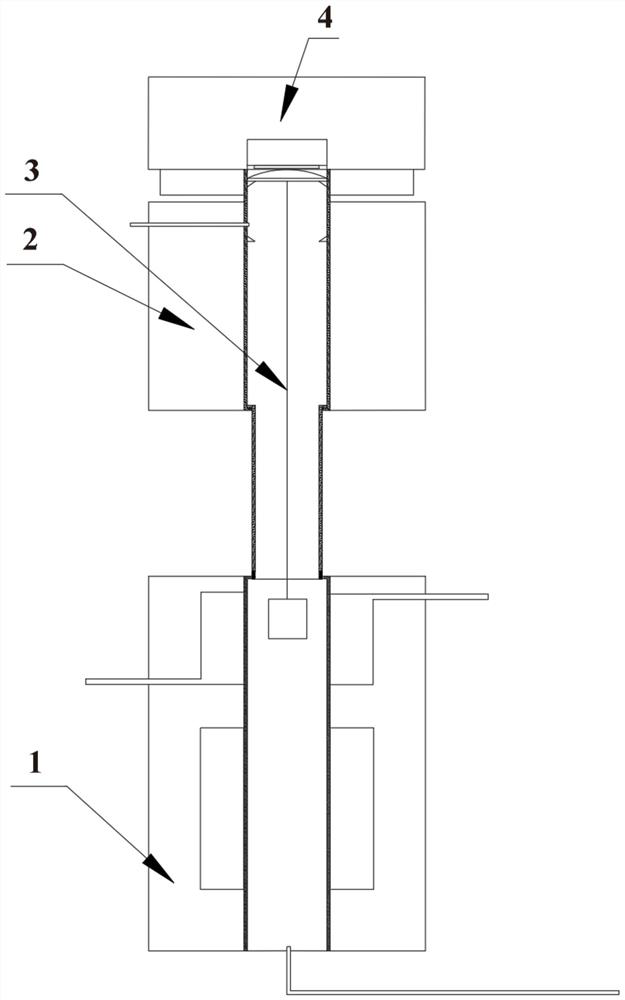

Rapid heating-atmosphere variable-weight real-time thermal analysis device and application

A thermal analysis device and atmosphere technology, applied in the field of heating experiment equipment, can solve problems such as low applicability, quality error, and inability to accurately measure the thermal burst of samples, so as to improve the scope of application and avoid quality errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

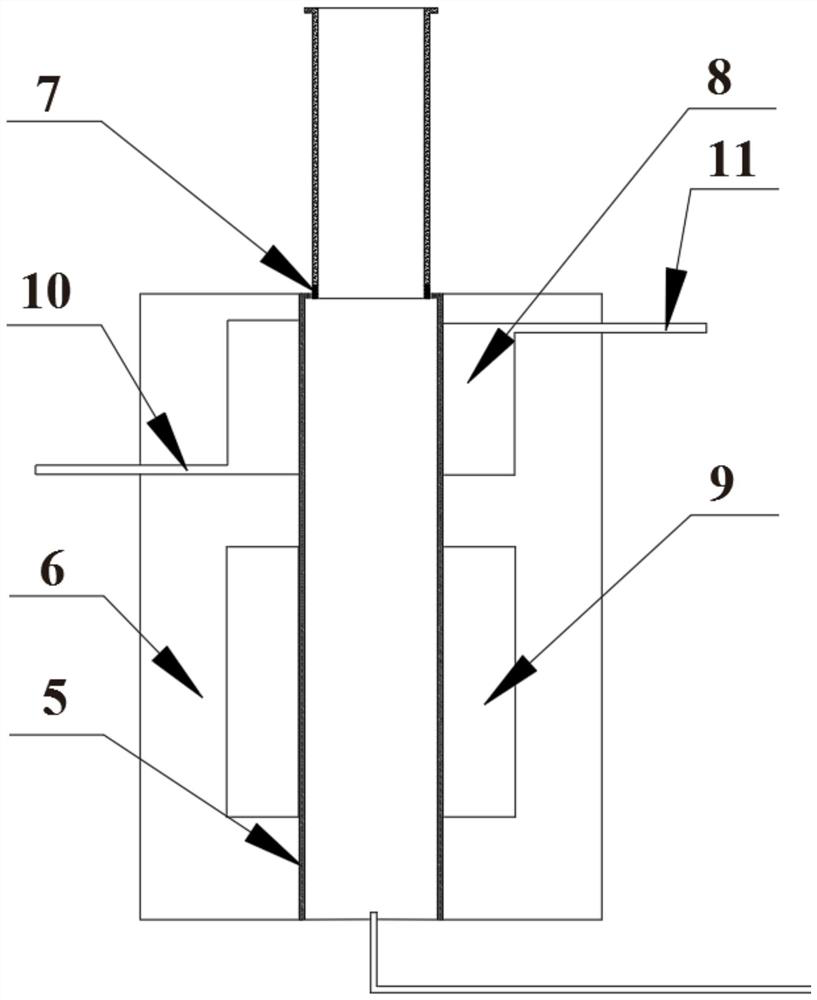

Method used

Image

Examples

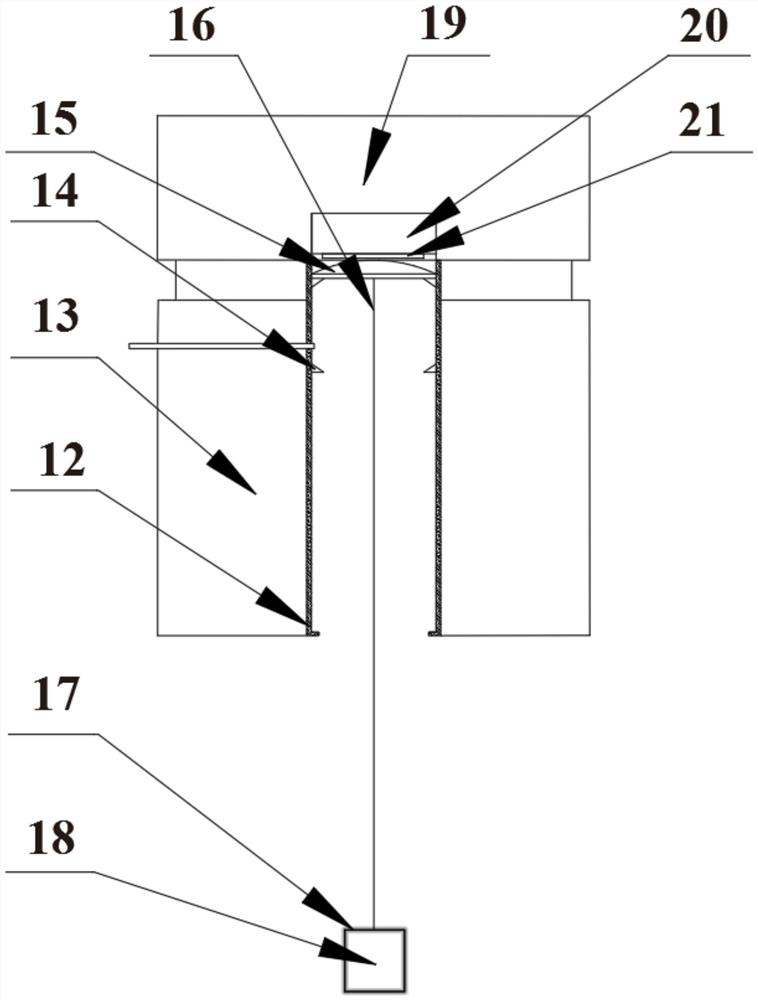

Embodiment 1

[0041] Turn on the power supply of the thermal analyzer, feed air from the air inlet pipe 15, remove the reaction shell 6, expose the reaction crucible 20 to the environment, open the electromagnet 22, and attract the convex type ferromagnetic material 17 due to the effect of magnetic force, making it Press the film pressure sensor 23 on the raised position, and the current pressure can be obtained through the potential difference,

[0042] By formula:

[0043] G=1000mg

[0044] Where G is the pressure (N), m is the mass (g), and g is the acceleration due to gravity (N / kg).

[0045] Calculate the zero mass.

[0046] Carry out real-time counting by computer, to return to zero weight peeling; Put into 200g Changzhi sludge then in reaction crucible 20, this moment because the increase of weight indirectly reduced electromagnet 22 to the suction force of raised type ferromagnetic material 17, thereby The pressure on the thin film pressure sensor 23 is reduced, and the weight re...

Embodiment 2

[0049] Turn on the power supply of the thermal analyzer, feed air from the air inlet pipe 15, remove the reaction shell 6, expose the reaction crucible 20 to the environment, open the electromagnet 22, and attract the convex type ferromagnetic material 17 due to the effect of magnetic force, making it Press the film pressure sensor 23 on the raised position, and the current pressure can be obtained through the potential difference,

[0050] By formula:

[0051] G=1000mg

[0052] Where G is the pressure (N), m is the mass (g), and g is the acceleration due to gravity (N / kg).

[0053] Calculate the zero mass.

[0054] Carry out real-time counting by computer, zero weight is peeled; Then in reaction crucible 20, put into 50g pyrite (FeS 2 ), this moment, because the increase in weight indirectly reduces the attraction of the electromagnet 22 to the raised ferromagnetic material 17, thereby reducing the pressure on the thin film pressure sensor 23, the weight recorded by the co...

Embodiment 3

[0057] Switch on the thermal analyzer power supply, pass into the gas distribution (21%O2) from the intake pipe 15 2 +79%CO 2 ), remove the reaction shell 6, expose the reaction crucible 20 to the environment, open the electromagnet 22, attract the raised ferromagnetic material 17 due to the magnetic force, and press the film pressure sensor 23 at the raised position, and pass the potential difference The current pressure can be obtained,

[0058] By formula:

[0059] G=1000mg

[0060] Where G is the pressure (N), m is the mass (g), and g is the acceleration due to gravity (N / kg).

[0061] Calculate the zero mass.

[0062] Carry out real-time counting by computer, zero weight is peeled; Put into 200g large grain coal gangue then in reaction crucible 20, this moment because the increase of weight has indirectly reduced the suction force of electromagnet 22 to raised type ferromagnetic material 17, Thereby reducing the pressure on the membrane pressure sensor 23, the weight...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com