Saccharum officinarum conveying mechanism of Saccharum officinarum harvesting and piling-up machine

A technology for delivering sugarcane and sugarcane, applied in the field of agricultural machinery and equipment, can solve the problems of lack of collection and collection function, easy crushing of sugarcane stalks, production reduction and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings. In the description of the present invention, the orientation words of "front", "rear", "left" and "right" are defined based on the perspective of the driver of the sugarcane harvester.

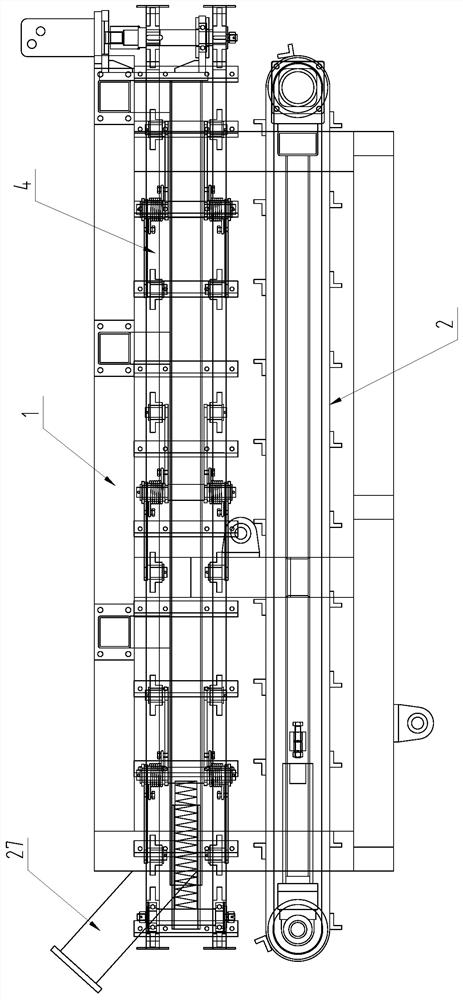

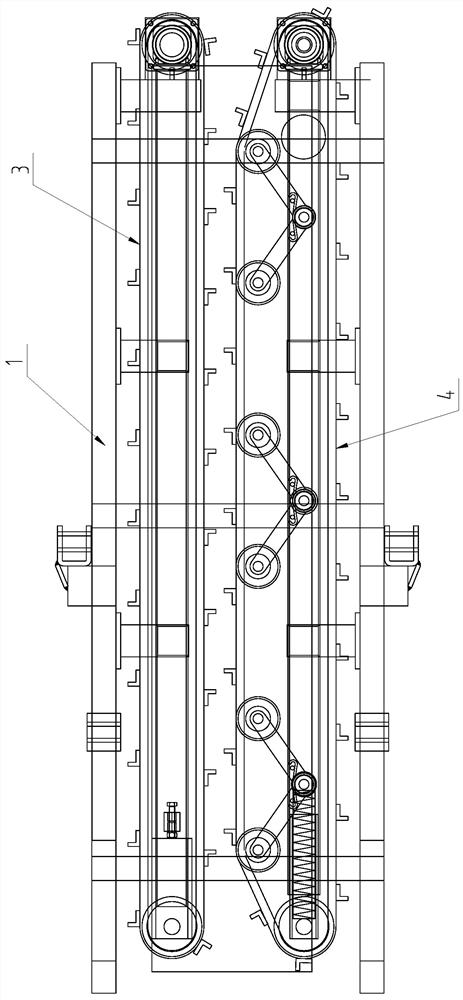

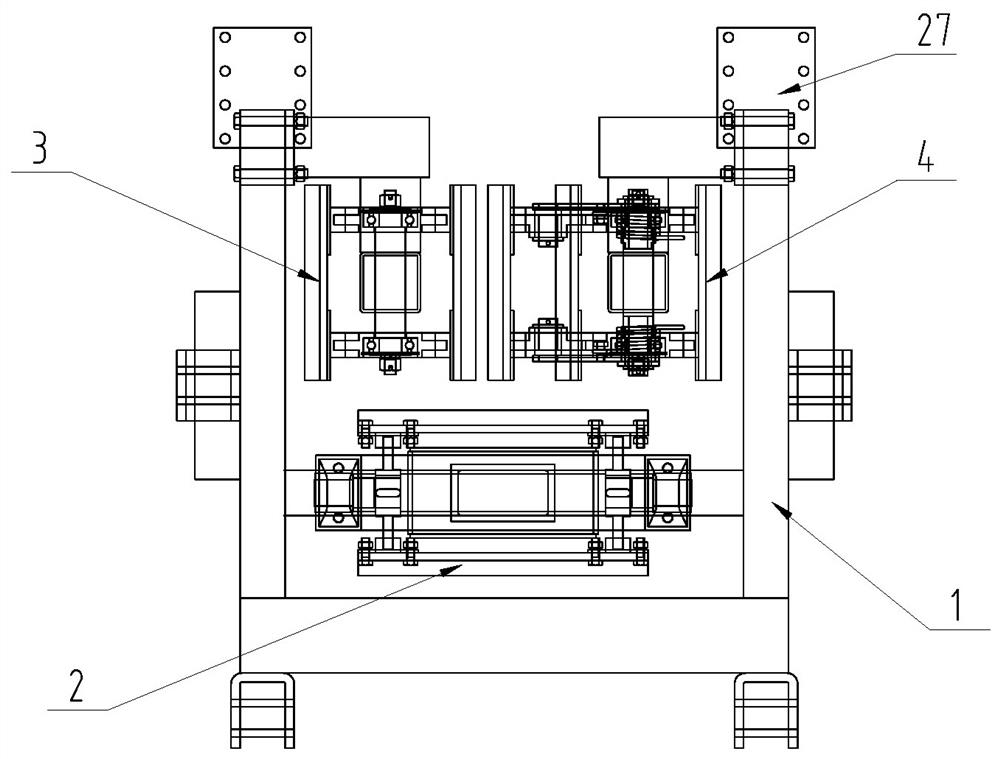

[0034] Such as Figure 1-4 As shown, the outside of the cane feeding mechanism of the sugarcane mower is provided with a U-shaped mounting frame 1, and the lower position of the mounting frame 1 is installed with a horizontal lower conveyor belt 2, and the position of the mounting frame 1 is installed with a vertical conveyor belt. The shape-setting entrainment belt 3 and the deformable entrainment belt 4 opposite to each other at intervals, the opposite sides of the shape-setting entrainment belt 3 and the deformable entrainment belt 4 are used as two clamping surfaces to jointly form a line above the lower conveyor belt 2 to adjust the clamping width adaptively according to the feed. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com