Needle strip electrode pulse pre-ionization crossflow Co2 laser discharge cavity

A technology of carbon dioxide and needle-strip electrodes, which is applied to lasers, laser components, laser components, etc., can solve problems such as injection power and laser output power difficulties, and achieve the effect of increasing laser power and electric power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

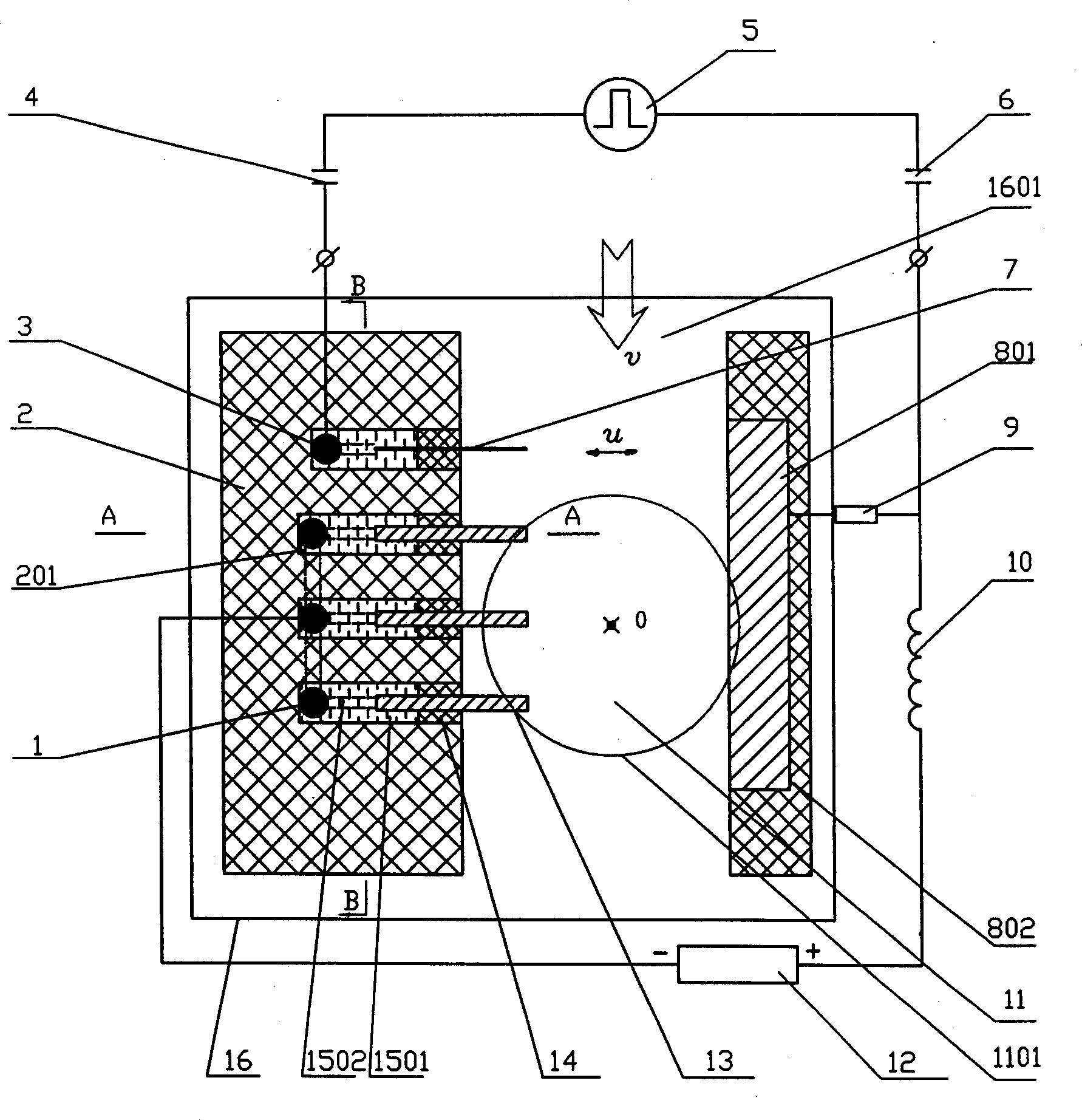

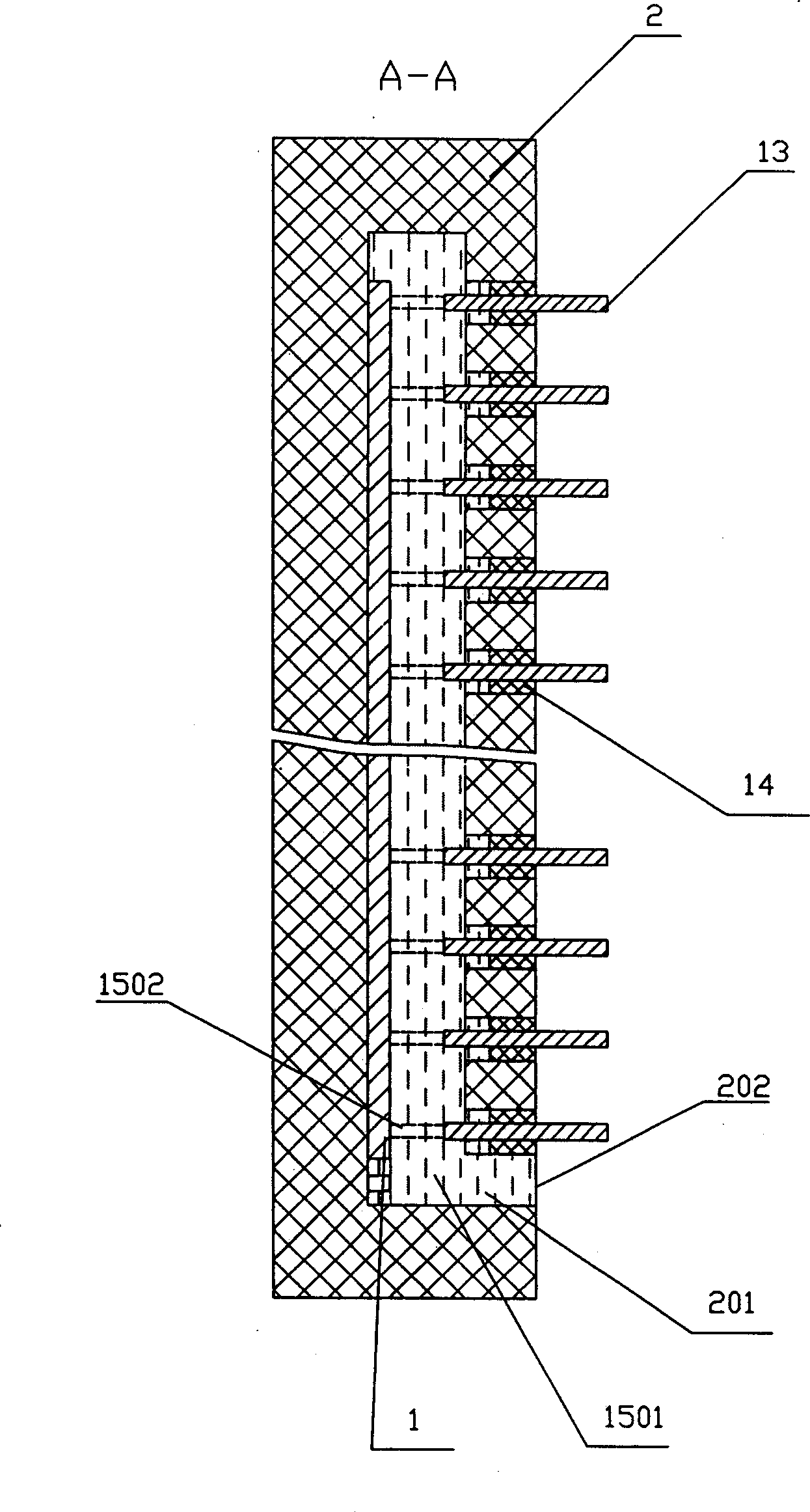

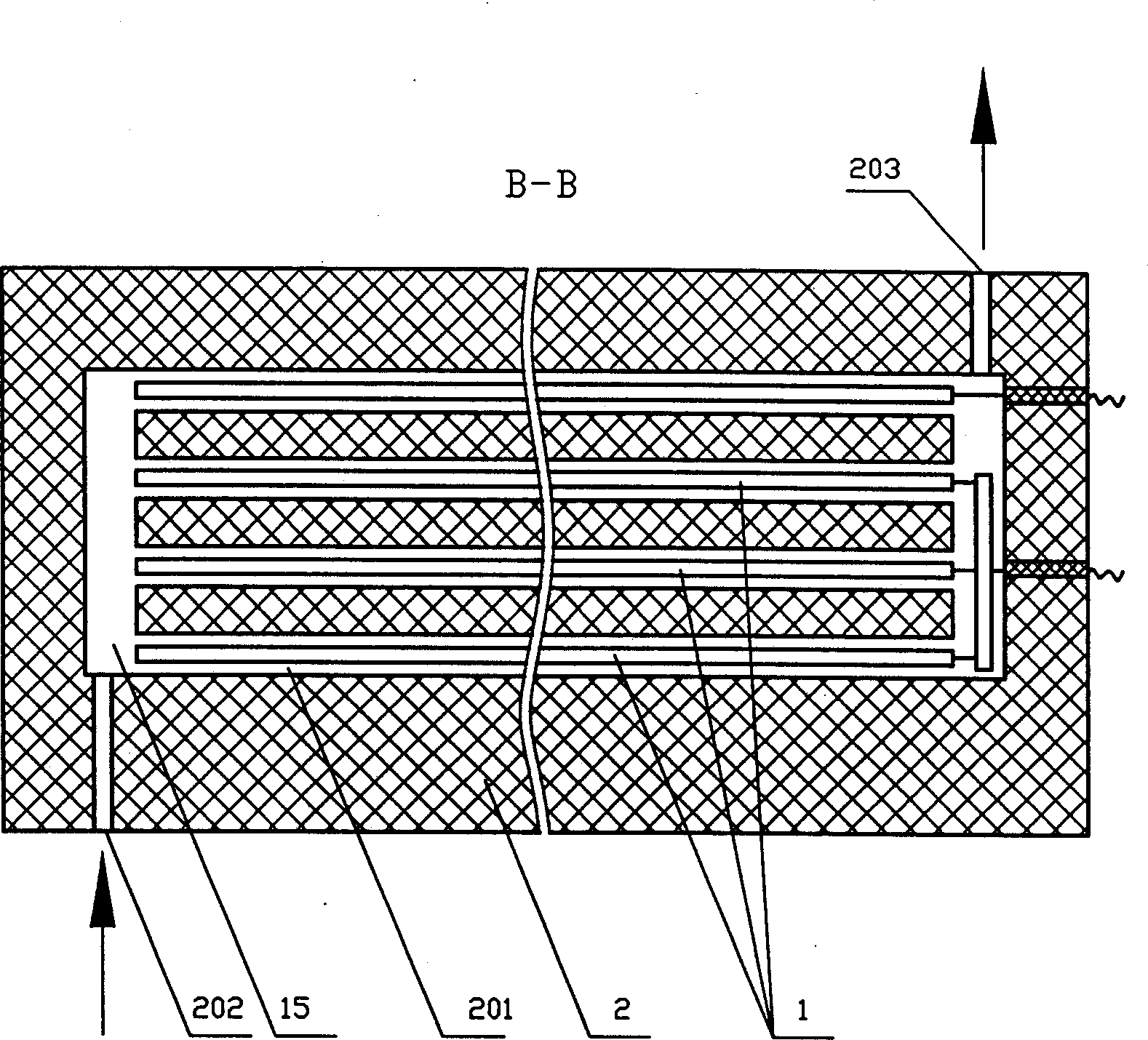

[0018] like figure 1 The structure shown at the Shanghai Institute of Optics and Fine Mechanics, Chinese Academy of Sciences, 5 kW cross-flow CO 2 implemented on the laser. CO in this example 2 The laser adopts dual axial fans (rotational speed 8000 rpm), dual discharge channels, and ∏-shaped folded cavity. like figure 1 The discharge area shown is divided into inner and outer sides. The length of the anode strips 801 is 50mm, the width of the anode strips 801 is 15mm, the distance between the anode strips 801 and the strips is 5mm, the anode strips 801 are embedded in the insulating plate 802 formed by the high temperature resistant insulating material, and are arranged in a row of the same plane . There are 57 anode strips 801 in each discharge area, and the effective discharge length is 1140mm. The one-to-one correspondence with each anode strip 801 is: the pulse pre-ionization needle 7 is made of Φ1mm copper needles, and the number of columns of the cathode needles 1...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap