Molecular film gas purification method applied to positive pressure respiratory system of closed protective clothing

A respiratory system and gas purification technology, applied in the field of respiratory devices, can solve problems such as wearing troubles, unusable devices, complex structures, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the following will further explain how the present invention is implemented in conjunction with the accompanying drawings and specific implementation methods.

[0020] The invention provides a molecular membrane gas purification method applied to a closed protective clothing positive pressure breathing system, comprising the following steps:

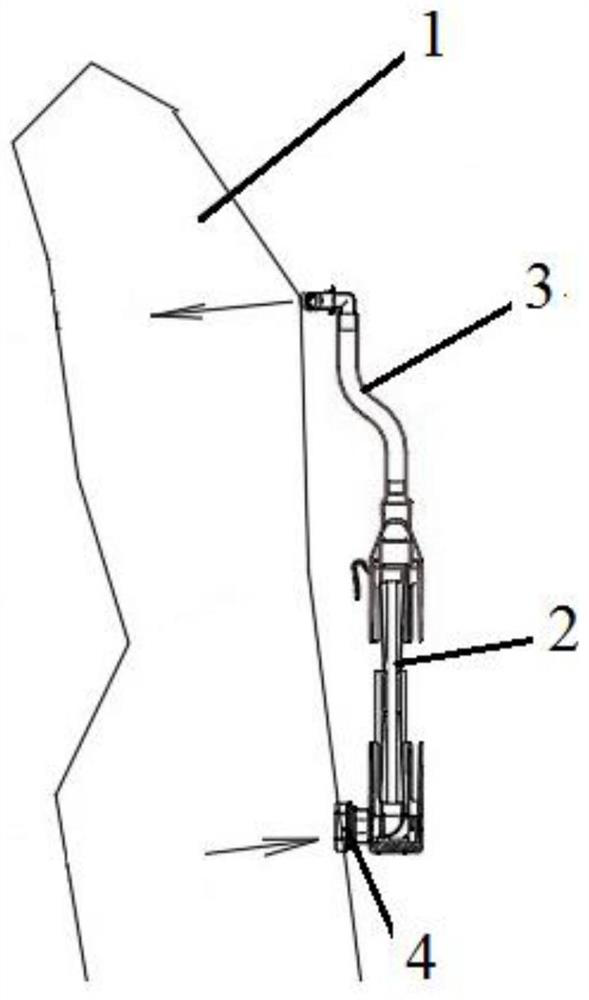

[0021] S1, ensure the internal circulation air pressure of the positive pressure breathing system of the closed protective clothing through the ventilation equipment, and extract the air exhaled by the wearer from the exhaust port of the closed protective clothing 1 and enter the pipeline;

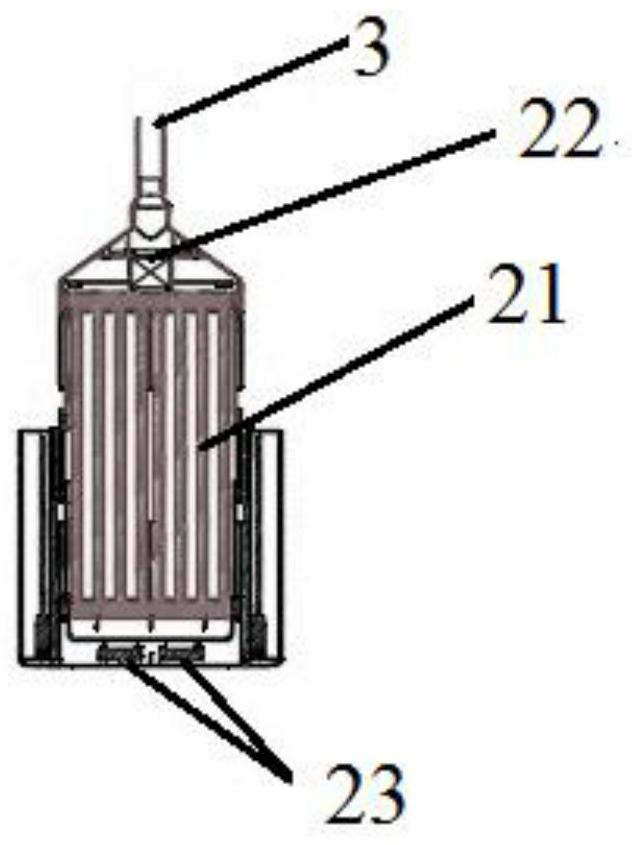

[0022] S2, the air exhaled by the wearer passes through the molecular membrane through the ventilation equipment, and the molecular membrane 21 is a membrane network for gas exchange composed of several hollow fiber m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com