Full-automatic remote control multi-station servo hydraulic machine

A servo-hydraulic machine, multi-station technology, applied in the field of stamping equipment, can solve problems such as the operator's inability to observe the transposition, the number of control buttons, and the stamping action error, and achieve the effect of solving industrial accidents, convenient carrying, and reducing the number of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

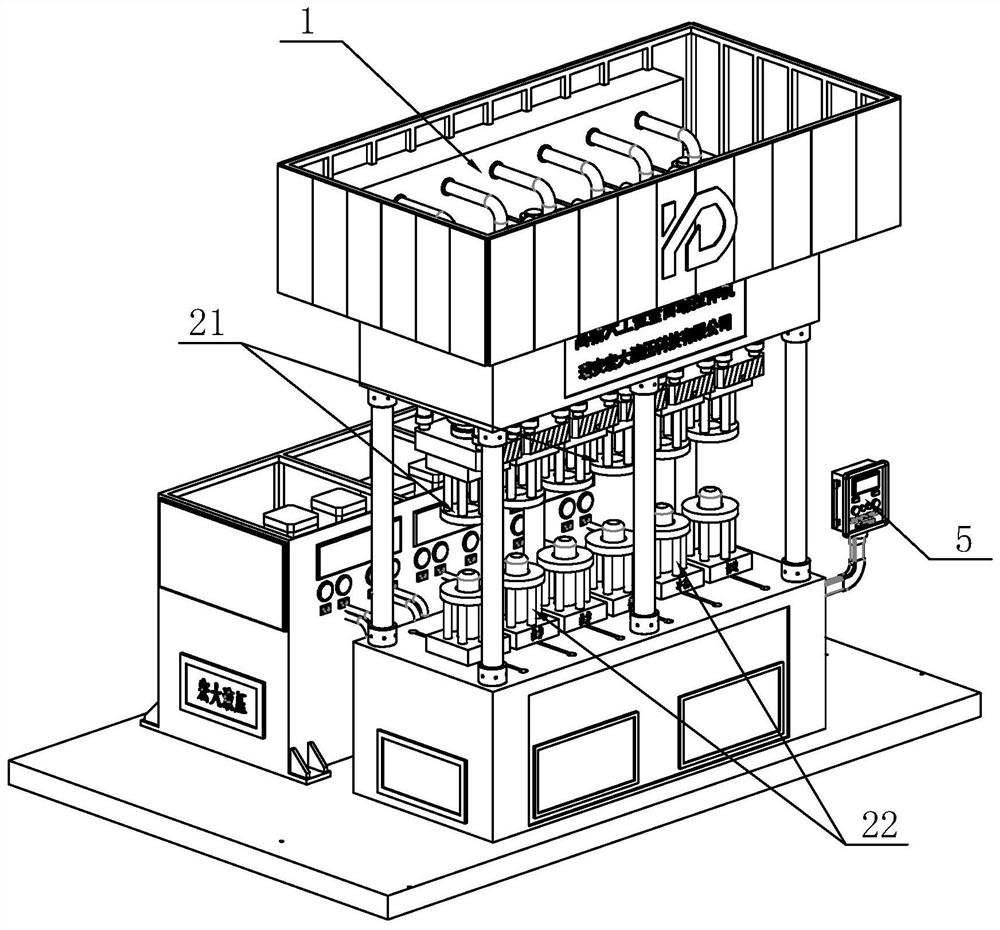

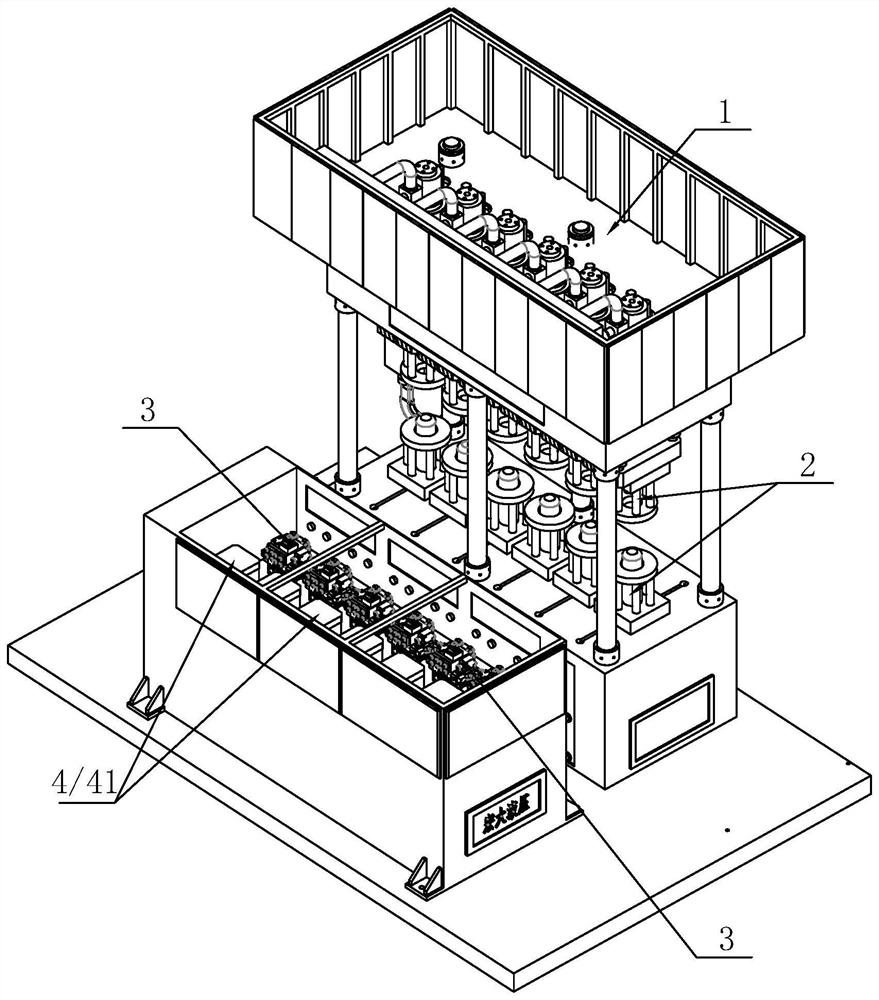

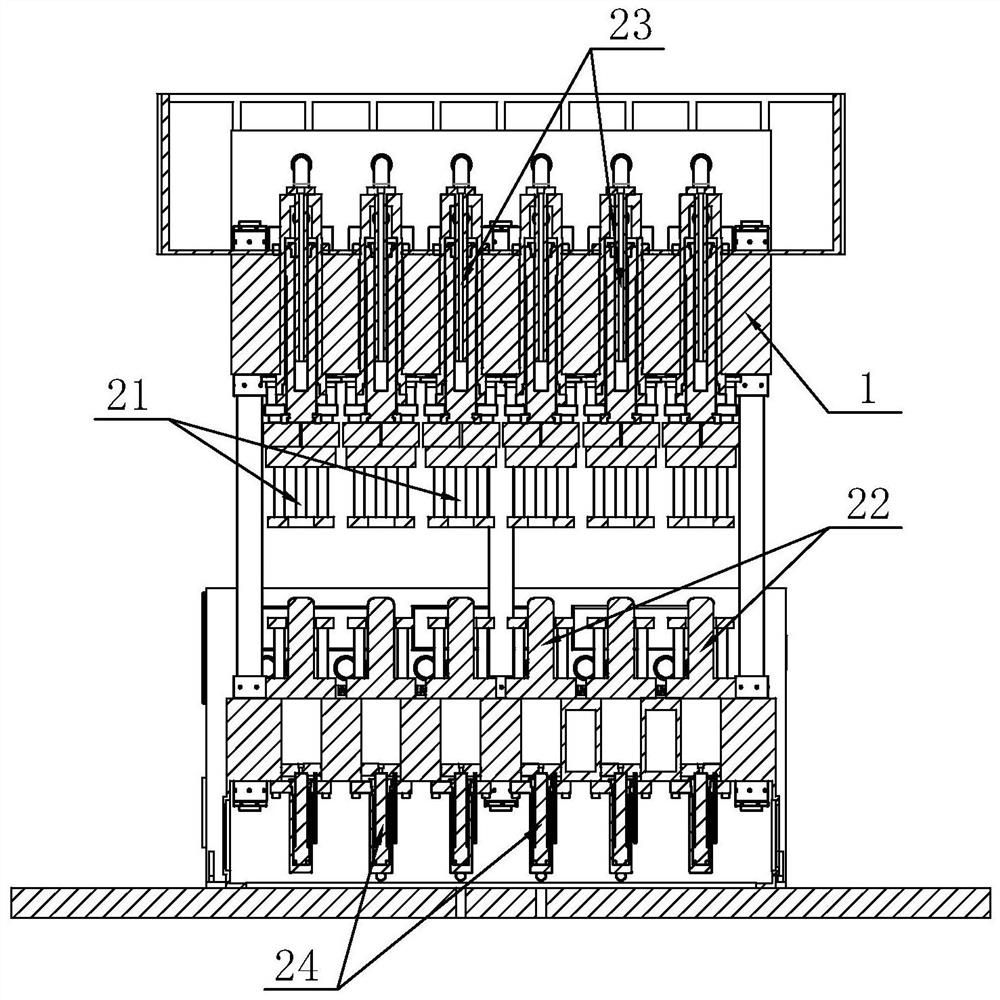

[0031] Such as Figure 1-Figure 4 As shown, the present invention discloses a fully automatic remote control multi-station servo hydraulic press, which includes a frame 1 on which 6 groups of stamping components 2 are arranged from left to right (the actual number of groups can be increased or decreased according to the production process) Each group of stamping assemblies 2 includes an upper stamping seat 21, a lower stamping seat 22, a stamping cylinder 23 and an ejection cylinder 24, and the stamping cylinder 23 is installed above the corresponding upper stamping seat 21 for controlling the upper stamping seat 21 to move up and down, and The ejection cylinder 24 is arranged under the corresponding lower stamping seat 22, and is used for demoulding after the wor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com