Intelligent automatic leather rubber product cutting machine

A technology for rubber products and cutting machines, used in welding/cutting auxiliary equipment, welding/welding/cutting items, manufacturing tools, etc., can solve the problems of finger cuts, low scrap rate, low hand protection, etc., to achieve easy cutting Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention is further described in conjunction with the following examples.

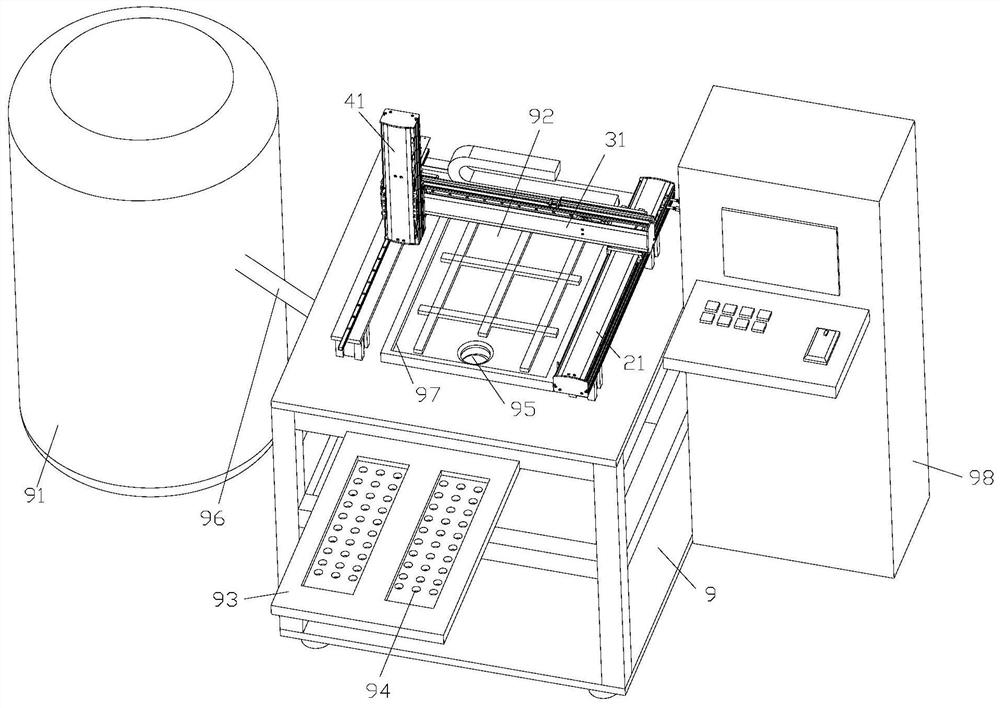

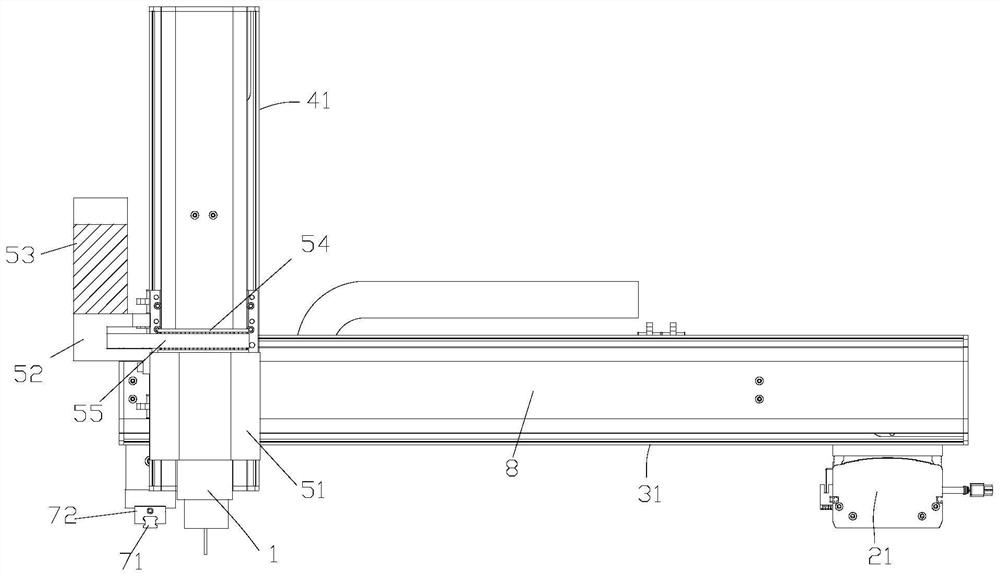

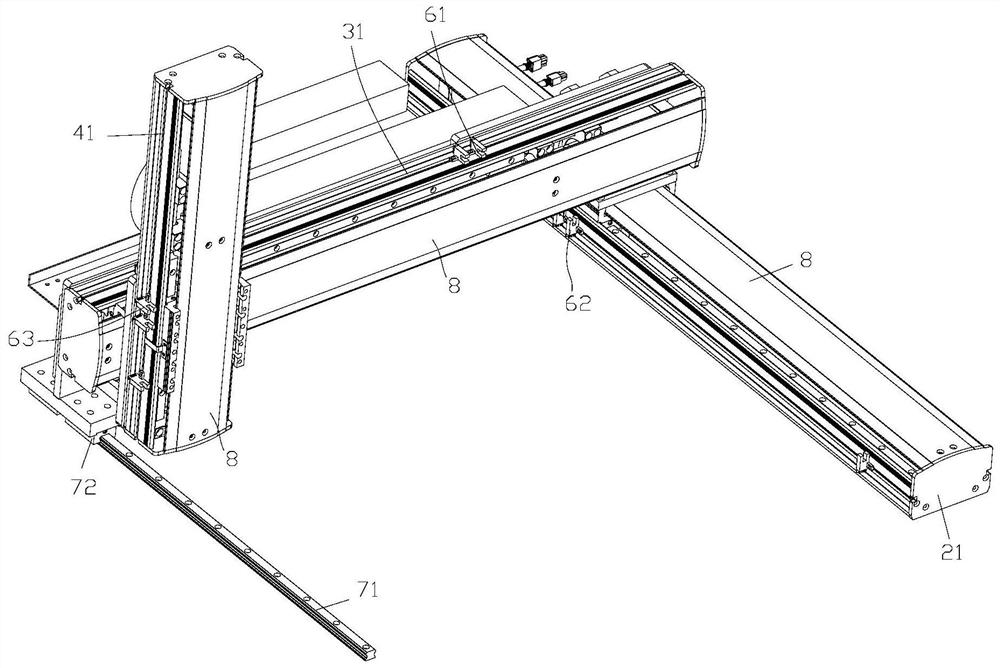

[0029] Depend on Figure 1 to Figure 4 It can be seen that a kind of intelligent automatic leather goods and rubber products cutting machine described in the present embodiment includes a frame 9 and a vacuum device 91; the frame 9 is provided with a workbench 92, a cutting head 1 and is used to drive the cutting head to move. The moving mechanism of described workbench 92 is provided with fixed mold 93; Described cutting head is located at the top of fixed mold 93; Described fixed mold 93 is provided with vacuum hole 94; Described vacuum device 91 communicates with vacuum hole 94 . The moving mechanism includes an X-axis driving mechanism, a Y-axis driving mechanism, a Z-axis driving mechanism and a rotation driving mechanism;

[0030] The rotary driving mechanism is used to drive the cutting head 1 to rotate; the Z-axis driving mechanism is used to drive the cutting head 1 to mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com