A production process for injection molds for producing plug parts

A technology of injection mold and production technology, which is applied in the field of injection mold production technology, can solve the problems of mold grinding and scrapping, and achieve the effects of improving clamping effect, not easy to jump, and improving polishing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The following is attached Figure 1-7 The application is described in further detail.

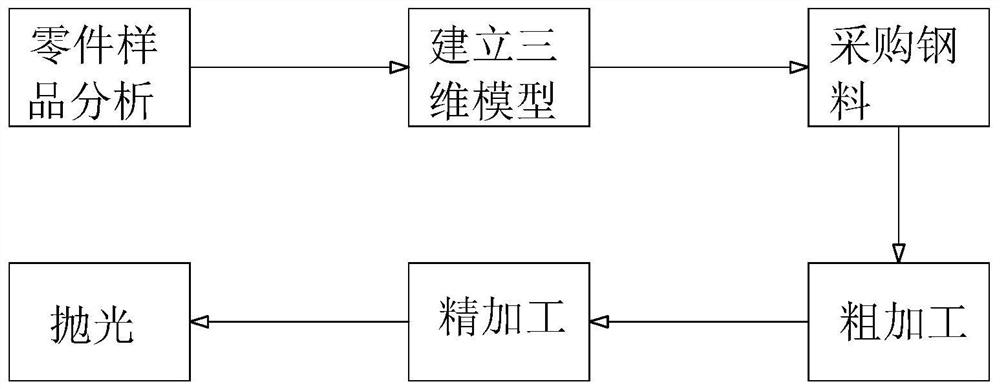

[0048] The embodiment of the present application discloses a production process of an injection mold for producing plug parts, referring to figure 1 , including the following steps:

[0049] S1: Part sample analysis;

[0050] S2: Carry out three-dimensional mold modeling for parts;

[0051] S3: Purchasing suitable steel materials according to customer requirements;

[0052] S4: Rough machining of steel materials by lathes, milling machines and other machine tools;

[0053] S5: Finishing rough blanks with high-precision machine tools such as wire-cut machine tools, electric spark piercers, and high-speed milling machines;

[0054] S6: Polish the mating surface of the mold by polishing equipment 1, and then manually polish the mold cavity.

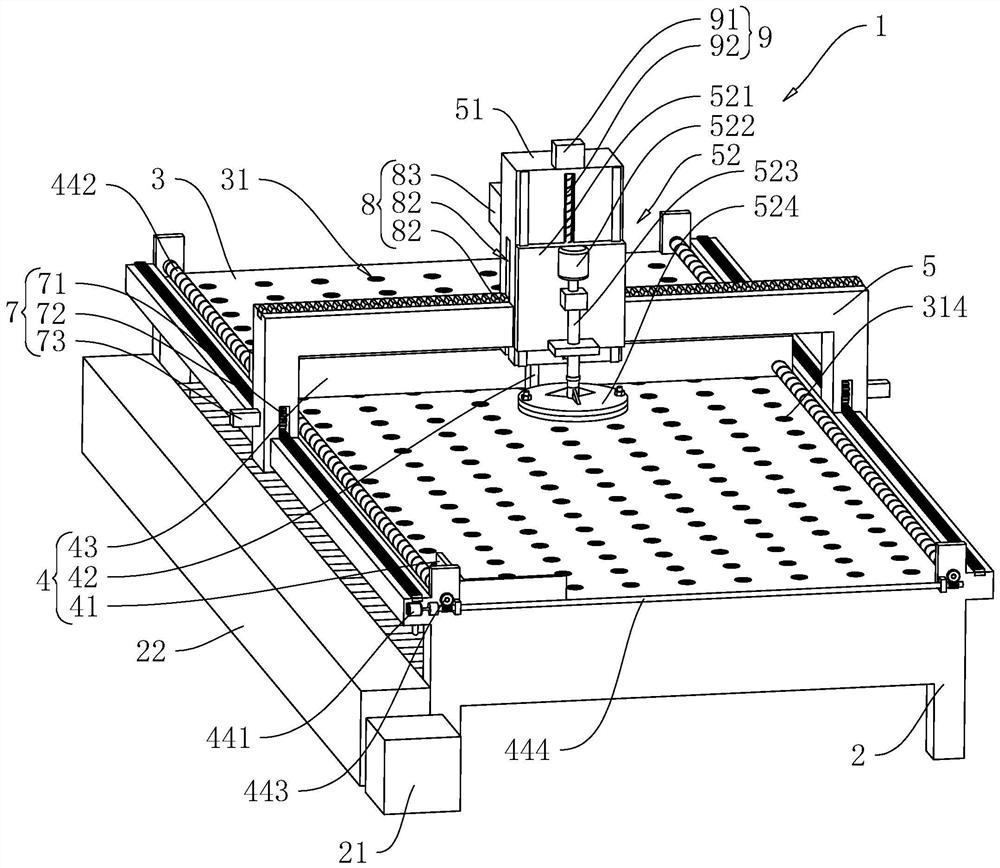

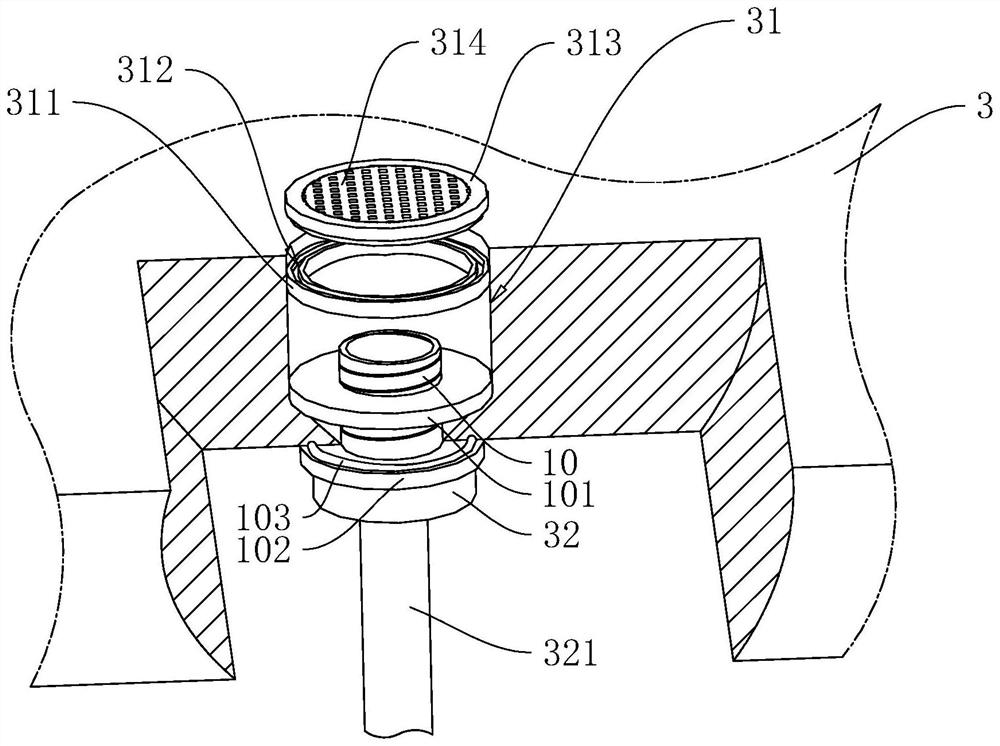

[0055] refer to figure 2 and image 3 , the polishing equipment 1 includes a frame 2 fixedly placed on the ground, a horizontal rectangul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com