Vacuum thermal forming system and forming method thereof

A technology of vacuum heating and forming mechanism, applied in the field of thermoforming, can solve the problems of affecting the forming quality of thermoforming effect products, reducing the processing efficiency of sheet thermoforming, and being difficult to disassemble and install the sheet, so as to ensure the quality of thermoforming and reduce the Thermal and physical waste, structurally novel effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] In order to better understand the present invention, the present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

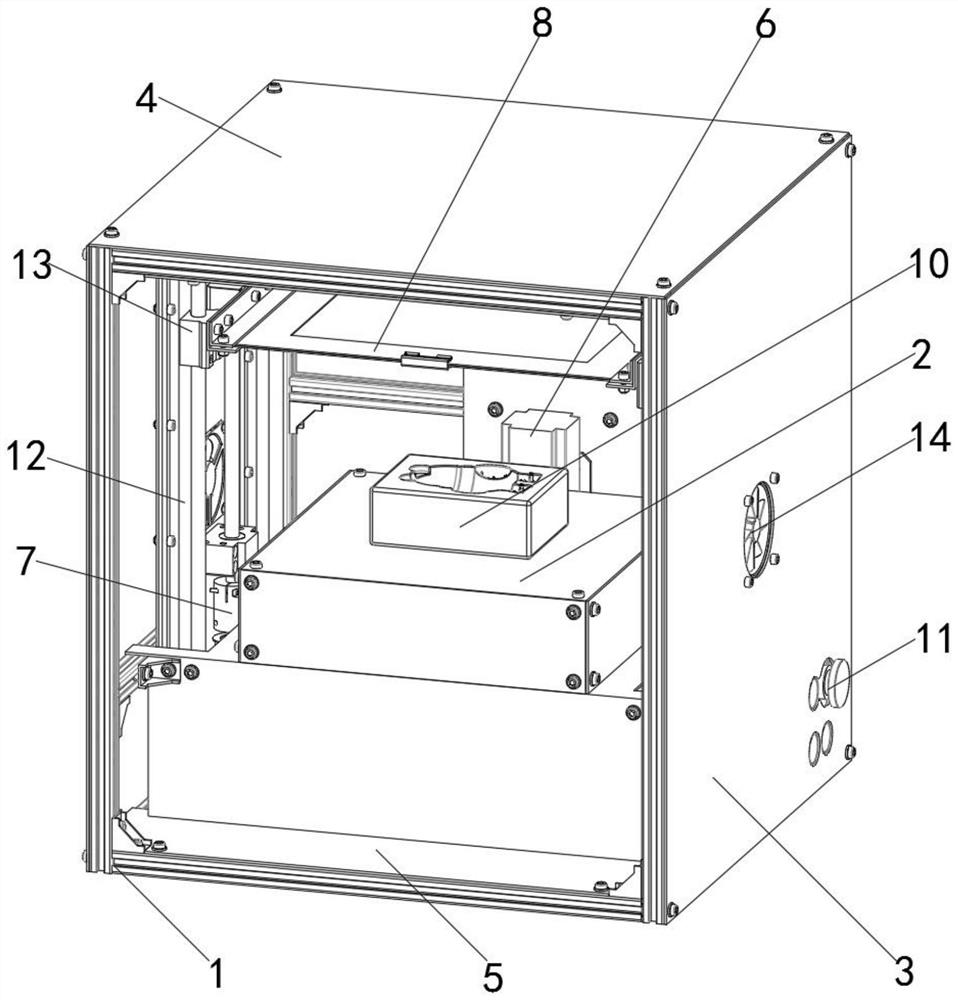

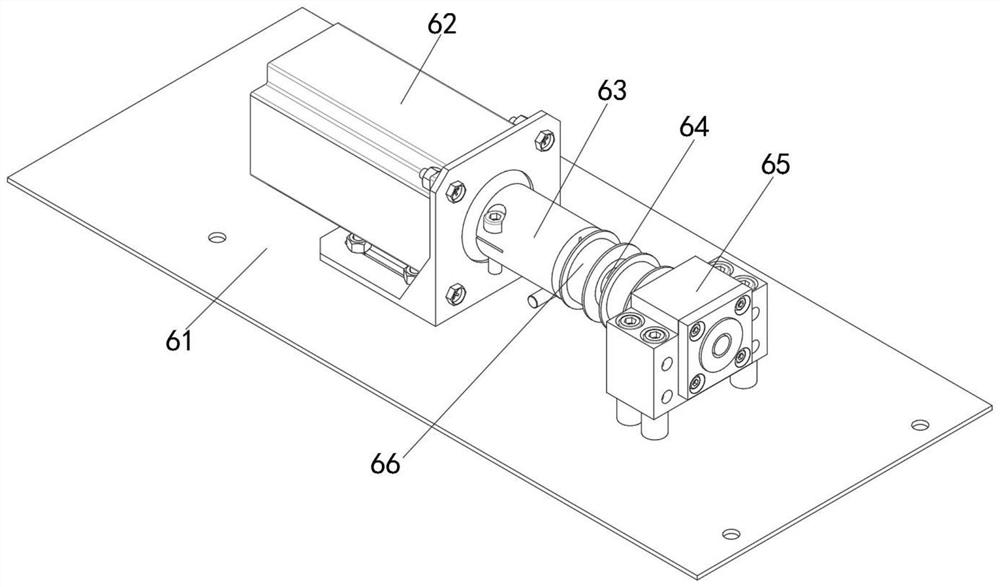

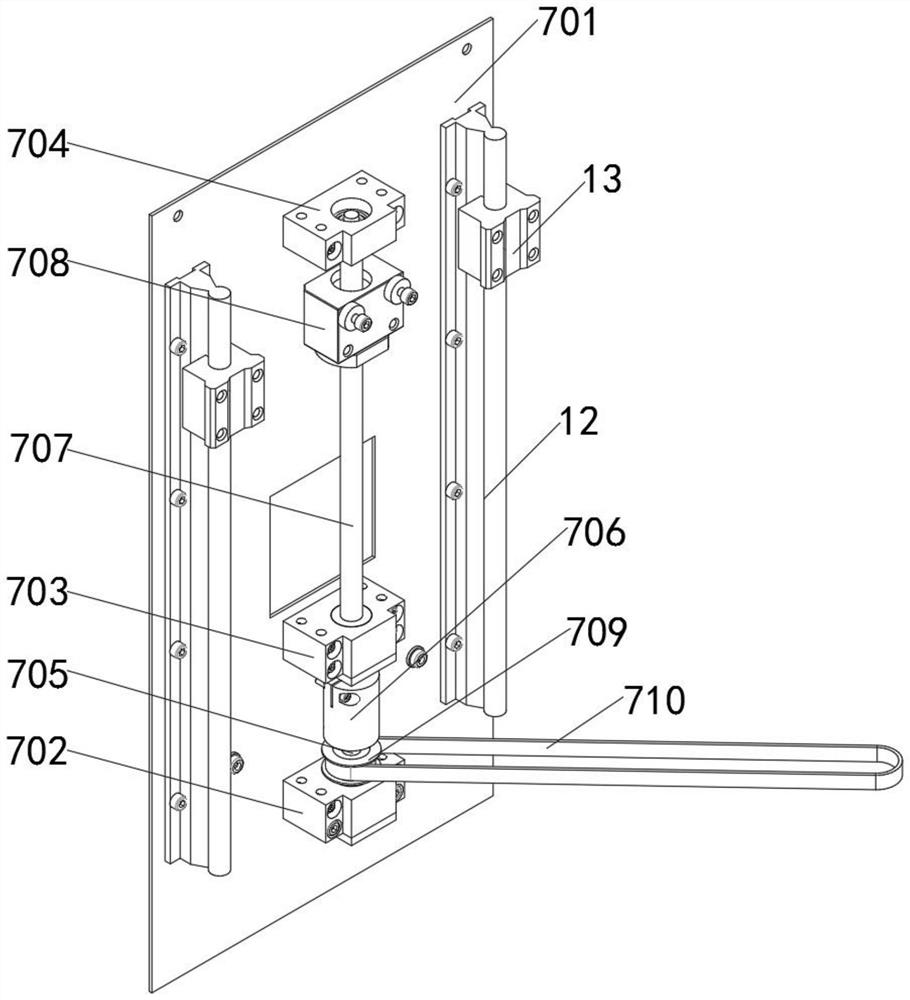

[0050] Such as figure 1 As shown, a vacuum thermoforming system consists of a frame 1, a workbench 2 arranged inside the frame 1, a side plate 3 connected to the side of the frame 1, a top plate 4 connected to the top of the frame 1, and a bottom plate connected to the bottom of the frame 1 Composed of 5, the frame 1 is provided with a drive mechanism 6 and a transmission mechanism 7, the output end of the drive mechanism 6 is connected to the input end of the transmission mechanism 7, and the transmission mechanism 7 is connected with a lamination mechanism 8, and the drive mechanism 6 passes through the transmission mechanism 7 Drive the lamination mechanism 8 to descend or rise, so that the lamination mechanism 8 carries out lamination or ejection along the vertical direction. The top and bott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com