A production system for canned tomato paste and a production process using the same

A production system, tomato paste technology, applied in mixers with rotating stirring devices, packaging, packaging sterilization, etc., can solve problems such as solid-liquid layering, water separation, etc., to increase uniformity, reduce possibility, reduce The effect of water phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

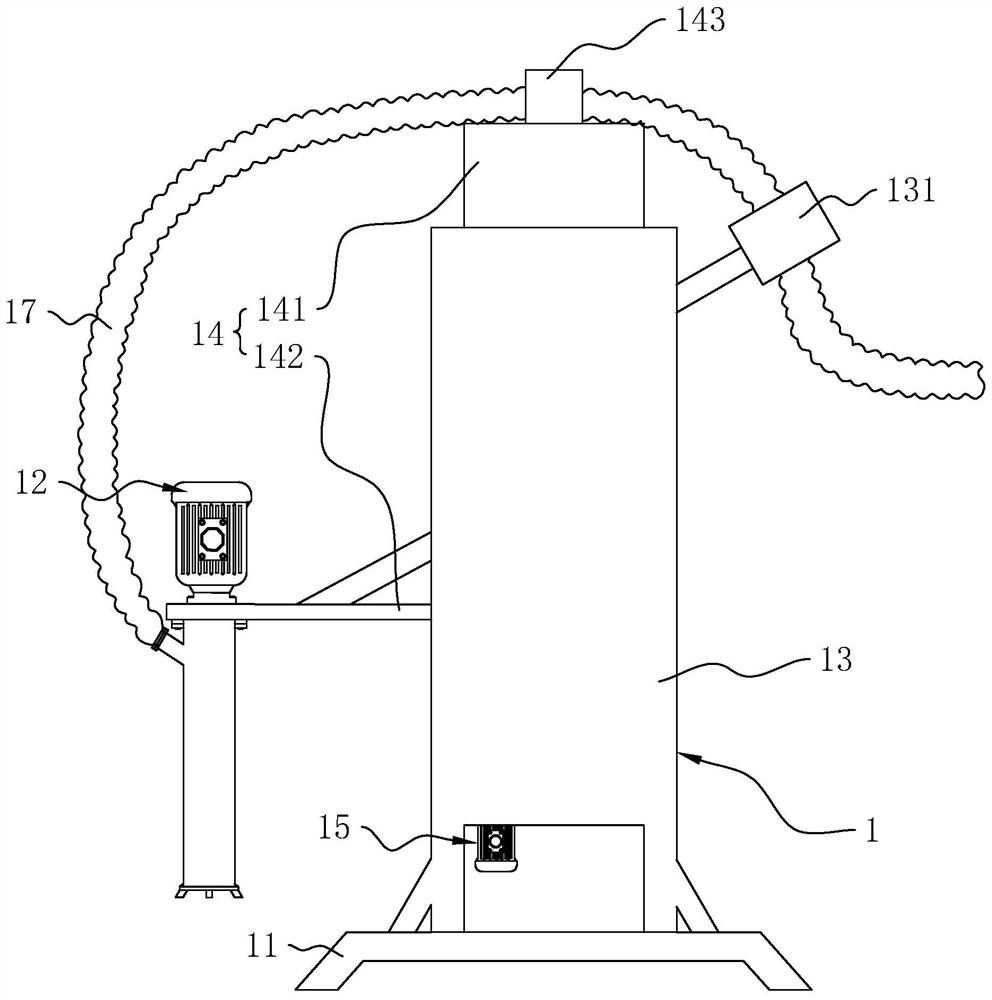

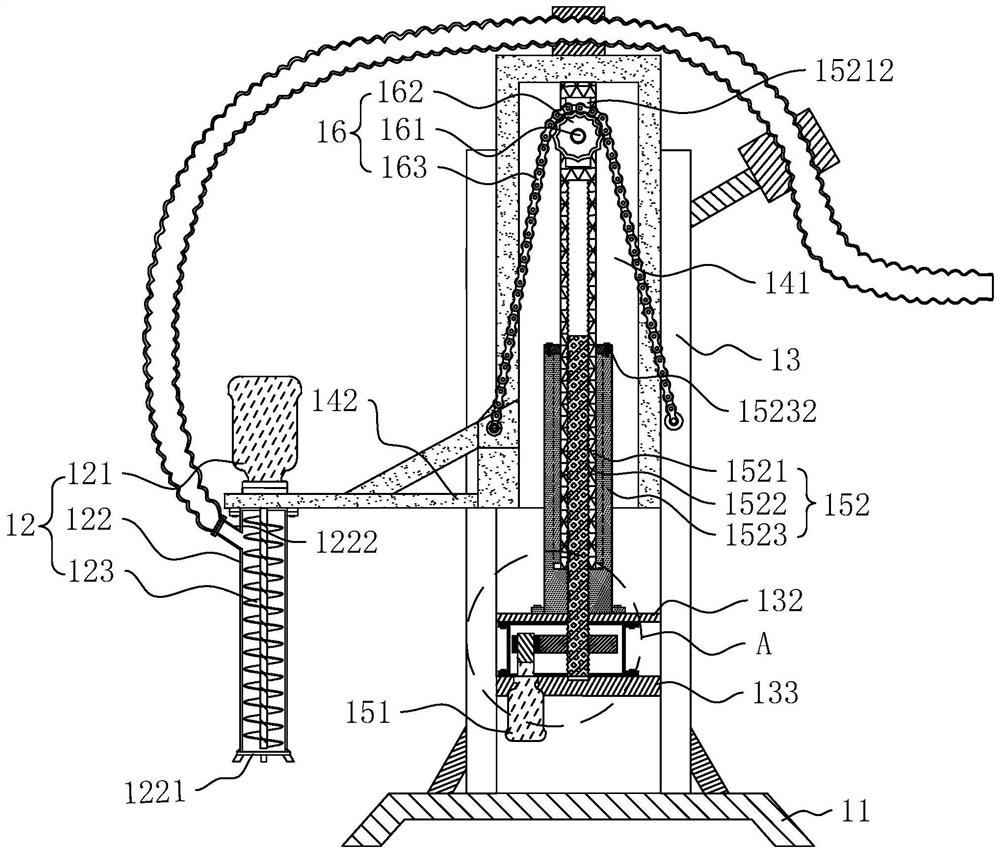

[0054] The following is attached Figure 1-13 The application is described in further detail.

[0055] The present application actually discloses a production system for canned tomato paste.

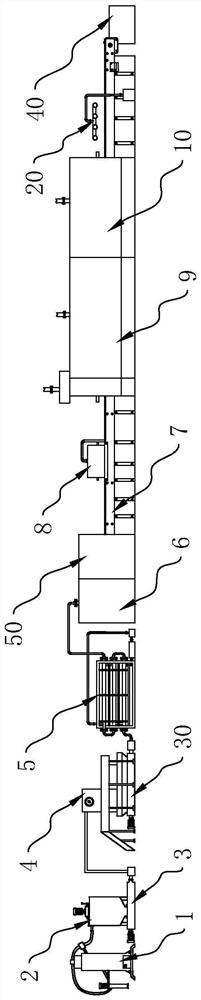

[0056] refer to figure 1 , a production system for canned tomato paste includes a sequentially connected feeding device 1, a pre-stirring device 2 for pre-stirring the tomato puree, and a first screw mixer for transporting the stirred slurry 3. A vacuum decompression concentration tank for concentrating and mixing the tomato puree 4. A second spiral mixer 30 for transporting the concentrated puree, and a tube tube for sterilizing the concentrated puree type heater 5, a filling machine 6 for canning tomato paste, a sealing machine 50 for sealing the canned body, a conveyor belt for conveying canned tomato paste 7, a Cleaning tank cleaning device 8 for cleaning the surface of tomato paste, high temperature sterilization box 9 for high temperature sterilization of canned tomato paste, co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com