Vegetative Porous Concrete Suitable for Plant Growth

A technology of porous concrete and plant growth, applied in botany equipment and methods, fertilizers made of biological waste, planting substrates, etc., can solve problems such as poor plant growth, reduce particle separation and water separation, improve and Workability, effect of reducing heat of hydration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

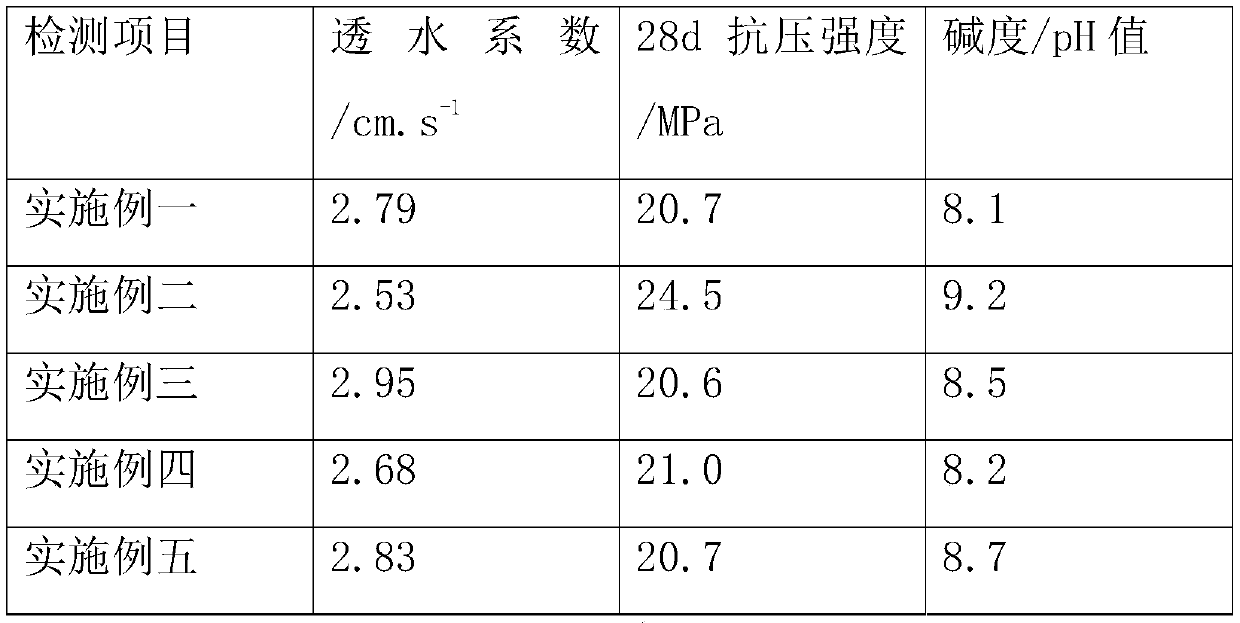

Examples

Embodiment 1

[0030] The plant-growing porous concrete suitable for plant growth provided by this embodiment includes porous concrete with thickness and mixed fine loam covered on the surface of the porous concrete, and the mixed fine loam consists of fine loam and soaked grass seeds in a weight ratio of 1 : The ratio of 2 is uniformly mixed, and the raw materials of the porous concrete include the following components according to the volume density: Portland cement 150kg / m 3 , Ceramsite 1495kg / m 3 , fly ash 86kg / m 3 , limestone powder 10kg / m 3 , fine loam 100kg / m 3 , plant ash 2kg / m 3 , rice husk charcoal 15kg / m 3 , Polycarboxylate superplasticizer 2.5kg / m 3 , EVA latex powder 20kg / m 3 , SBR powder 17kg / m 3 , polyacrylate emulsion 13kg / m 3 , organic compost 20kg / m 3 , vermiculite 15kg / m 3 , seaweed powder 2kg / m 3 , tea meal 0.5kg / m 3 , neem cake 2kg / m 3 , polyacrylamide 0.7kg / m 3 , ferrous sulfate 0.5kg / m 3 , Modified loofah fiber 3kg / m 3 , Silicone defoamer 0.8kg / m 3 , w...

Embodiment 2

[0048] The plant-growing porous concrete suitable for plant growth provided by this embodiment includes porous concrete with thickness and mixed fine loam covered on the surface of the porous concrete, and the mixed fine loam consists of fine loam and soaked grass seeds in a weight ratio of 1 : The ratio of 3 is uniformly mixed, and the raw materials of the porous concrete include the following components according to the volume density: Portland cement 325kg / m 3 , Ceramsite 1550kg / m 3 , fly ash 60kg / m 3 , limestone powder 12kg / m 3 , fine loam 120kg / m 3 , plant ash 3kg / m 3 , rice husk charcoal 30kg / m 3 , Polycarboxylate superplasticizer 4kg / m 3 , EVA latex powder 10kg / m 3 , SBR powder 40kg / m 3 , polyacrylate emulsion 23kg / m 3 , organic compost 30kg / m 3 , Vermiculite 20kg / m 3 , seaweed powder 3kg / m 3 , tea meal 0.7kg / m 3 , neem cake 3kg / m 3 , polyacrylamide 1.2kg / m 3 , ferrous sulfate 1kg / m 3 , modified loofah fiber 4kg / m 3 , Silicone defoamer 1kg / m 3 , water 9...

Embodiment 3

[0066] The plant-growing porous concrete suitable for plant growth provided by this embodiment includes porous concrete with thickness and mixed fine loam covered on the surface of the porous concrete, and the mixed fine loam consists of fine loam and soaked grass seeds in a weight ratio of 1 : The ratio of 2 is uniformly mixed, and the raw materials of the porous concrete include the following components according to the volume density: Portland cement 220kg / m 3 , Ceramsite 1500kg / m 3 , fly ash 58kg / m 3 , limestone powder 11kg / m 3 , fine loam 110kg / m 3 , plant ash 2kg / m 3 , rice husk charcoal 17kg / m 3 , polycarboxylate superplasticizer 2.9kg / m 3 , EVA latex powder 16kg / m 3 , SBR powder 30kg / m 3 , polyacrylate emulsion 16kg / m 3 , organic compost 27kg / m 3 , seaweed powder 2.5kg / m 3 , vermiculite 17kg / m 3 , tea meal 0.6kg / m 3 , neem cake 2.5kg / m 3 , Polyacrylamide 1.0kg / m 3 , ferrous sulfate 0.7kg / m 3 , Modified loofah fiber 3.5kg / m 3 , Silicone defoamer 0.9kg / m ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com