Fly ash and preparation method thereof

A technology of fly ash and stone powder, applied in the field of fly ash and its preparation, can solve problems such as environmental pollution, achieve the effects of reducing environmental pollution, reducing preparation costs, and improving the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

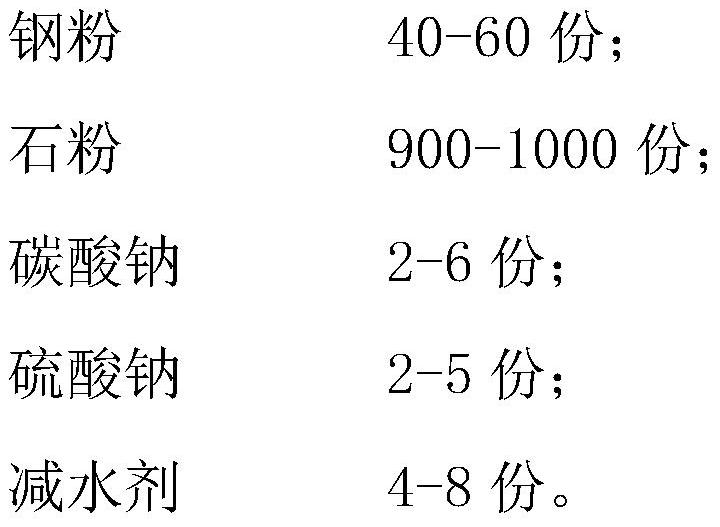

[0030] Step 1, first weigh each component by the following parts by weight:

[0031]

[0032] The mesh number of described steel powder is 325-350 mesh;

[0033] Step 2: Put the stone powder into the grinder to grind, and get the ground stone powder above 325 mesh;

[0034] Step 3: put the steel powder, ground stone powder obtained in step 2, sodium carbonate, sodium sulfate, and water reducer in turn into a powder feeder, stir evenly, and then pack to obtain the fly ash.

Embodiment 2

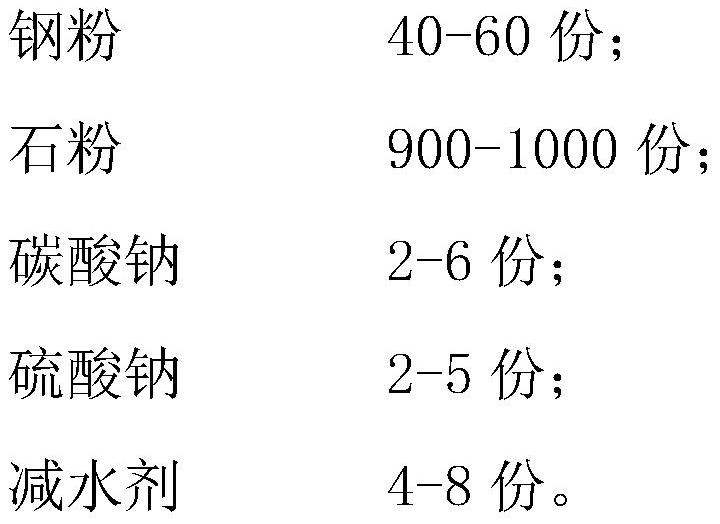

[0036] Step 1, first weigh each component by the following parts by weight:

[0037]

[0038]

[0039] The mesh number of the steel powder is 325-350 mesh.

[0040] Step 2: Put the stone powder into the grinder to grind, and get the ground stone powder above 325 mesh;

[0041] Step 3: put the steel powder, ground stone powder obtained in step 2, sodium carbonate, sodium sulfate, and water reducer in turn into a powder feeder, stir evenly, and then pack to obtain the fly ash.

Embodiment 3

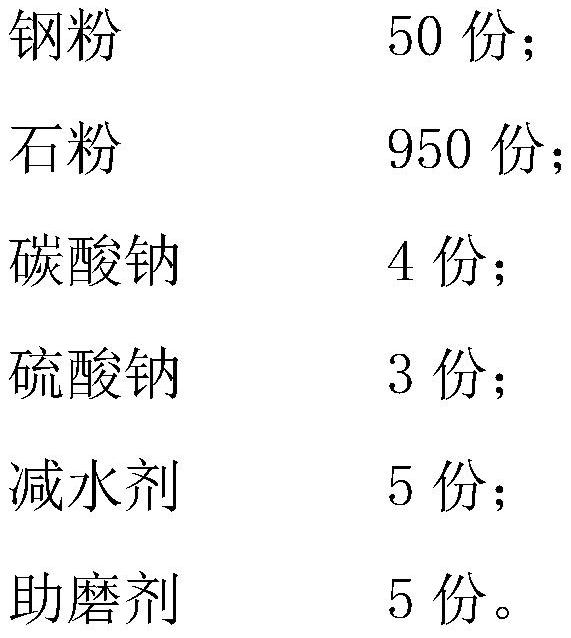

[0043] Step 1, first weigh each component by the following parts by weight:

[0044]

[0045] The mesh number of the steel powder is 325-350 mesh, and the grinding aid is triethanolamine.

[0046] Step 2: Put the stone powder and grinding aid into the grinder to grind, and get the ground stone powder above 325 mesh;

[0047] Step 3: put the steel powder, ground stone powder obtained in step 2, sodium carbonate, sodium sulfate, and water reducer in turn into a powder feeder, stir evenly, and then pack to obtain the fly ash.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesh | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com