Aluminum alloy with high thermal conductivity and preparation method thereof

An aluminum alloy and high thermal conductivity technology, applied in the field of aluminum alloys, can solve the problems of poor thermal conductivity, difficult to meet the rapid heat dissipation of parts, and achieve improved thermal conductivity, excellent casting performance and flow filling performance, and high thermal conductivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

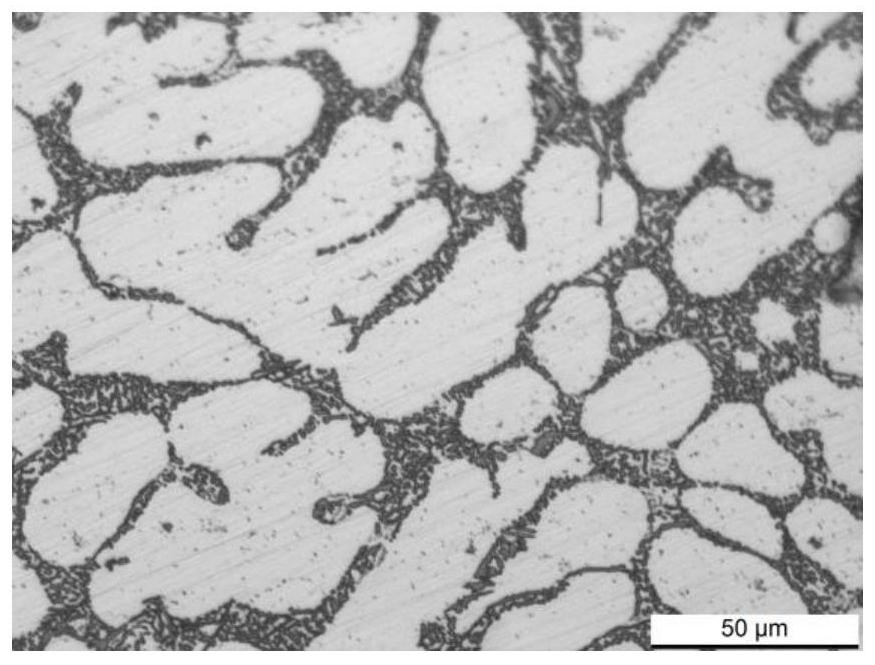

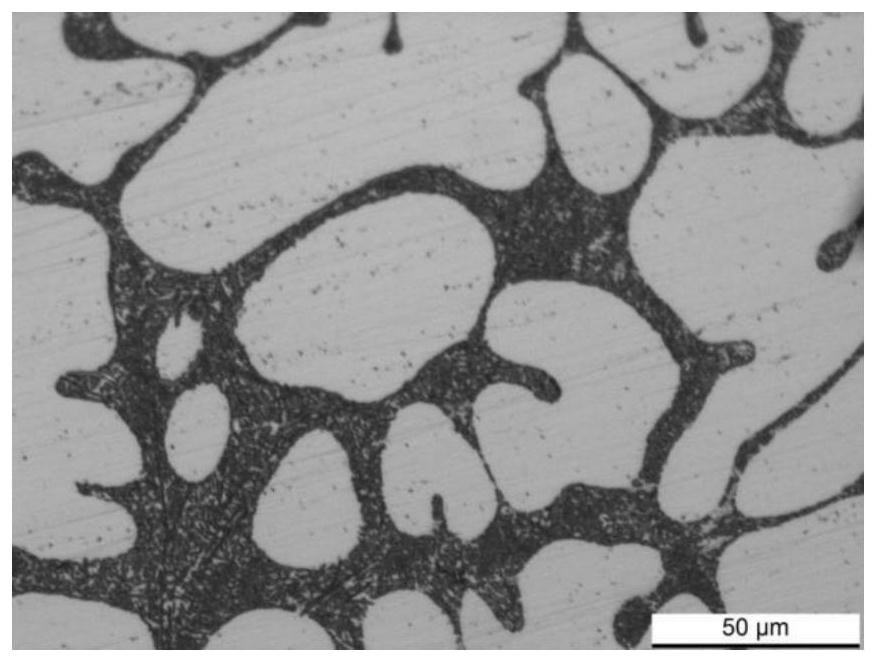

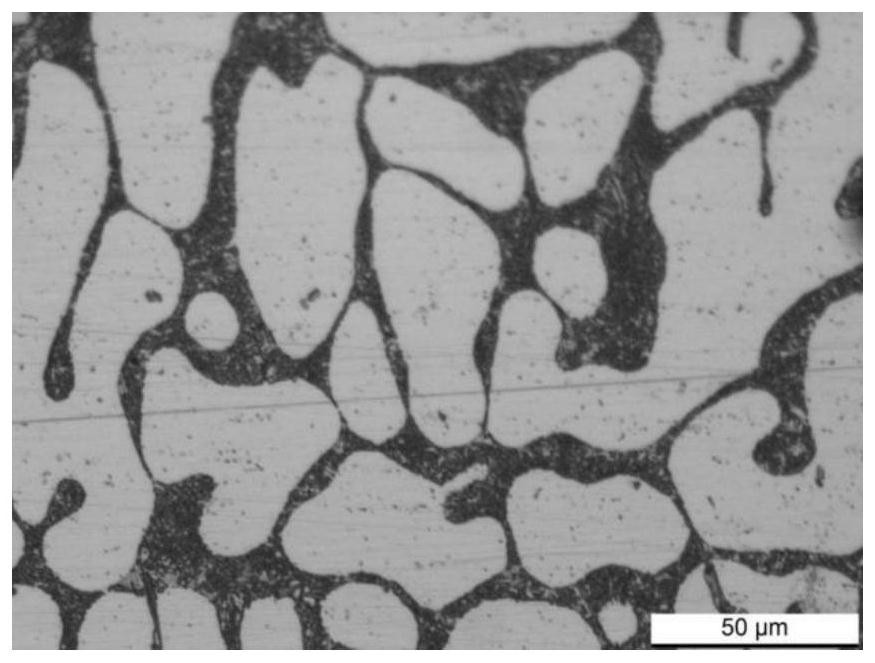

Image

Examples

preparation example Construction

[0066] As an embodiment of the present application, the preparation method of the high thermal conductivity aluminum alloy of the present application includes the following steps:

[0067] S1. Heating the aluminum ingot to melt the aluminum ingot into aluminum liquid, adding Si, Ni, Cu, Sr, Mg and B to the aluminum liquid to melt together into aluminum alloy liquid, refining and removing slag from the aluminum alloy liquid to obtain aluminum alloy to be cast alloy liquid;

[0068] S2. Casting the aluminum alloy liquid to be cast into an aluminum alloy ingot, and heat-treating the aluminum alloy ingot to obtain an aluminum alloy with high thermal conductivity.

[0069] Among them, considering the production cost and controlling the inevitable impurity content, the aluminum ingot selected in this application is an aluminum ingot with an aluminum content ≥ 99.8%.

[0070] In this embodiment, the specific operation of step S1 is: heating the aluminum ingot to heat and melt it int...

Embodiment

[0078] Table 1 shows some examples of the specific content of each component in the high thermal conductivity aluminum alloy of the present invention. It should be pointed out that the specific content of each component of the high thermal conductivity aluminum alloy of the present invention is not limited to the data in Table 1.

[0079] Table 1 Examples of High Thermal Conductivity Aluminum Alloy Content

[0080]

[0081] Table 2 shows some examples of main process parameters in the preparation method of the high thermal conductivity aluminum alloy of the present invention.

[0082] Table 2 Specific examples of production process parameters of high thermal conductivity aluminum alloy

[0083]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com