Basement construction method based on socket type steel plate water stop belt

A technology of steel plate waterstop and construction method, applied in water conservancy projects, underwater structures, infrastructure engineering, etc., can solve the problems of complex installation and dismantling process, affecting the construction period, cumbersome construction process, etc., so as to avoid welding The quality is not easy to control, the effect of improving construction efficiency and improving waterproof quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

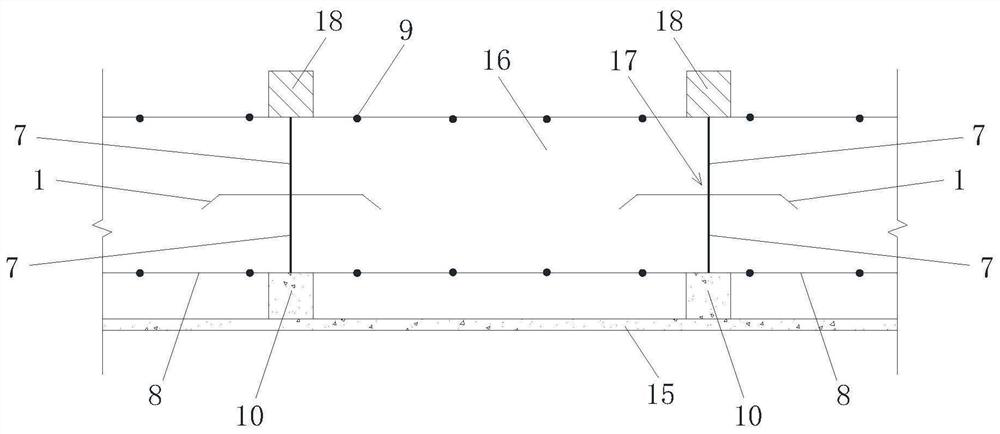

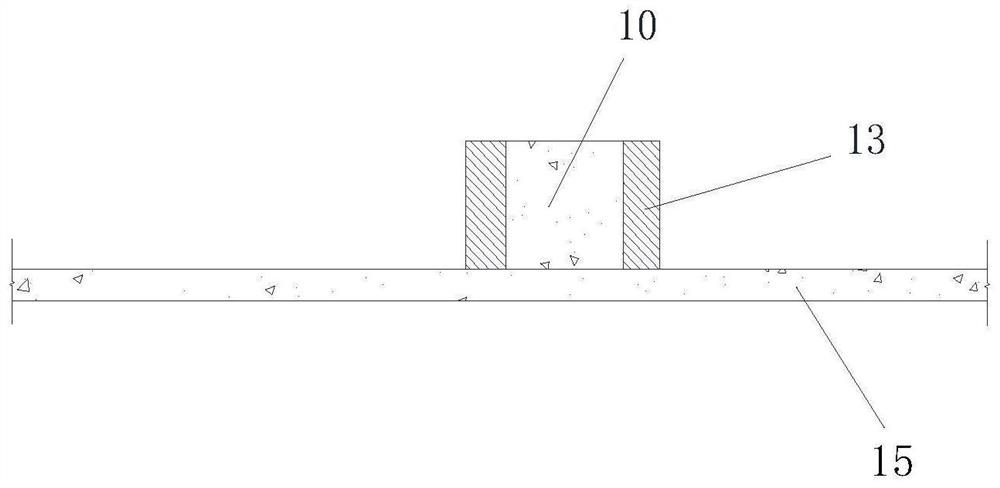

[0087] Such as Figure 11 Shown is a basement construction method based on a socket-type steel plate waterstop. The basement to be constructed includes a basement floor, a basement roof directly above the basement floor, and a basement roof supported between the basement floor and the basement roof. Load-bearing structure, the basement floor and the basement roof are cast-in-place reinforced concrete slabs arranged horizontally, and the load-bearing structure is a cast-in-place reinforced concrete structure; figure 1 , the said cast-in-place reinforced concrete slab is provided with a bottom steel mesh 8 and a surface layer steel mesh 9 directly above the bottom layer steel mesh 8, and the bottom layer steel mesh 8 and the surface layer steel mesh 9 are all arranged horizontally; the basement The bottom plate is laid on the foundation cushion 15, and the foundation cushion 15 is a concrete cushion arranged horizontally;

[0088] When constructing the basement, the process is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com