Coal mine goaf treatment and collapse backfill slurrying and grouting device

A technology for grouting devices and gobs, applied in safety devices, fillings, mining equipment, etc., can solve the problems of difficulty in sealing grouting holes, high labor intensity of workers, small construction space, etc., and achieve space saving , Reduce labor intensity and save cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

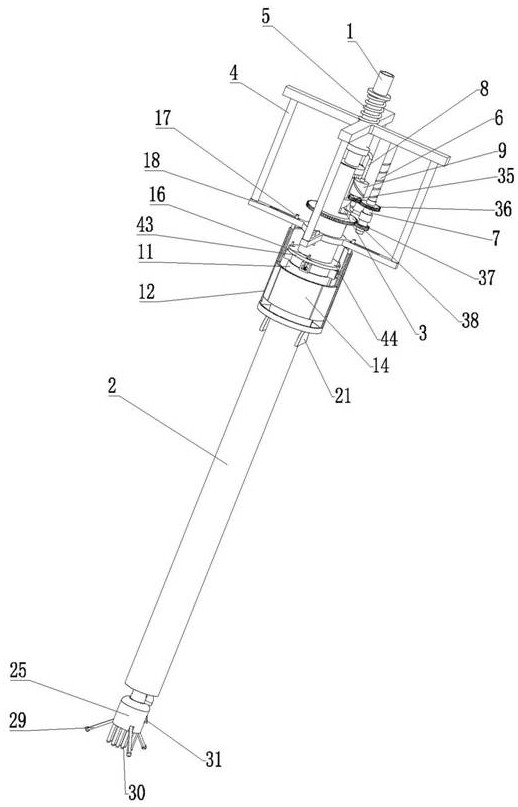

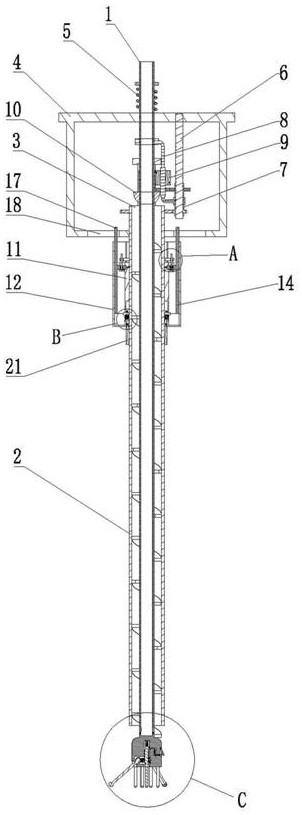

[0025]Embodiment 1, a grouting device for coal mine goaf control and subsidence backfilling, including a screw rod 1 with a vertical axis, the screw rod 1 is a hollow structure, and the upper end of the screw rod 1 is connected with a drilling machine. Take the machine to support and drive the screw rod 1. The upper end of the screw rod 1 is connected with the grouting pump. The grouting pump is used for grouting after drilling. The outer wall of the screw rod 1 is surrounded by spiral blades. The first cylinder 2 is sleeved, the screw blade is placed in the first cylinder 2, the part without the helical blade at the upper end of the screw rod 1 is placed above the first cylinder 2, and the upper end of the first cylinder 2 is connected to the screw rod through the bearing. 1 Rotational connection, the upper end of the outer wall of the first cylinder 2 is provided with a plurality of discharge ports 3, the discharge ports 3 are used to discharge the broken rock drilled during ...

Embodiment 2

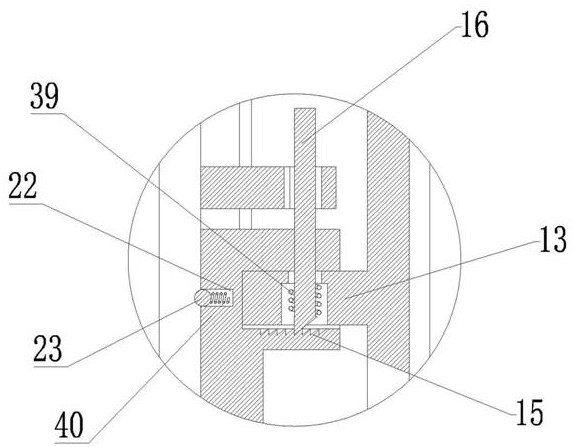

[0027] Embodiment 2, on the basis of Embodiment 1, a plurality of cylindrical grooves 22 are distributed on the inner wall of the second cylinder 11, the axes of the cylindrical grooves 22 are arranged radially along the second cylinder 11, and the cylindrical grooves 22 are slidably connected with The positioning glass bead 23, the fifth spring 41 is connected between the bottom wall of the cylindrical groove 22 and the positioning glass bead 23, and the fifth spring 41 gives the positioning wave bead a thrust toward the axis of the first cylinder 2, and the first cylinder 2 An annular groove is provided on the outer wall, and one end of the positioning glass bead 23 is placed in the annular groove, and the other end of the positioning glass bead 23 is placed in the cylindrical groove 22. When the first cylinder 2 passes through the second cylinder 11 and moves to the second When the outer wall of the first cylinder 2 is in contact with the positioning glass bead 23, the posit...

Embodiment 3

[0028] Embodiment 3, on the basis of Embodiment 1, a plurality of pulp outlets 24 are hinged on the lower end of the outer wall of the screw rod 1, and the plurality of pulp outlets 24 correspond to a plurality of pulp outlets one by one, and the screw rod 1 and the pulp outlet The door 24 is connected by a torsion spring, and the pulp outlet 24 is used in conjunction with the pulp outlet. In the initial state, the pulp outlet 24 is in sealing contact with the pulp outlet under the action of the torsion spring. The slurry opening is blocked by the crushed rocks drilled, and when the high-pressure grouting is performed, the slurry outlet door 24 is opened under the pressure of the high-pressure slurry, and the slurry can flow out from the slurry outlet.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com