Air suction silencing cavity with buffer device

The technology of a buffer device and silencing cavity, which is applied to liquid variable volume machinery, variable volume pump components, machines/engines, etc., can solve the problems such as the need to improve the sound silencing section, the limited noise reduction ability, and the large suction pulsation noise, etc. Achieve good noise reduction, improve frequency characteristics, and reduce inspiratory fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

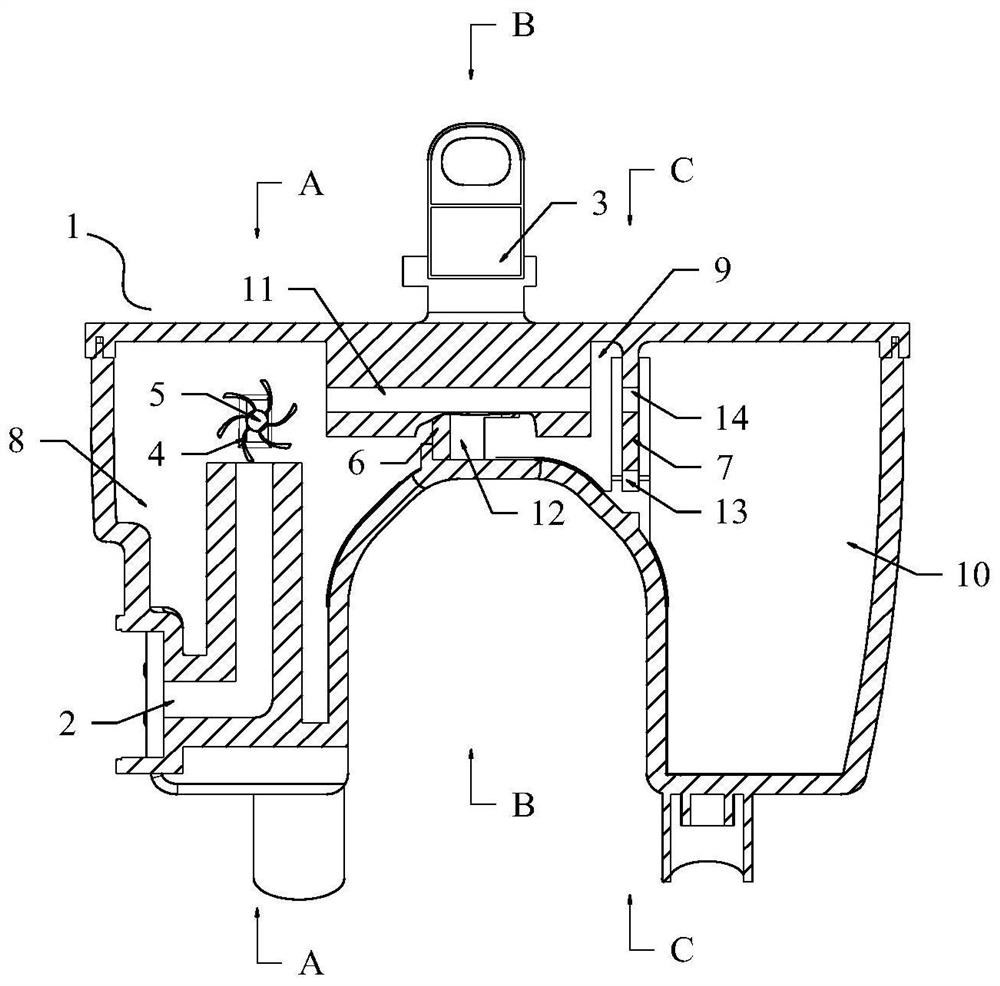

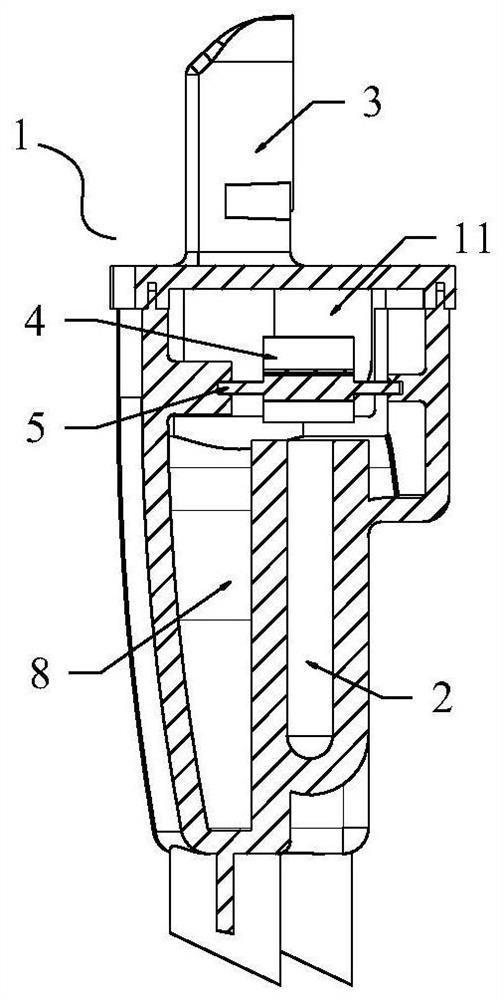

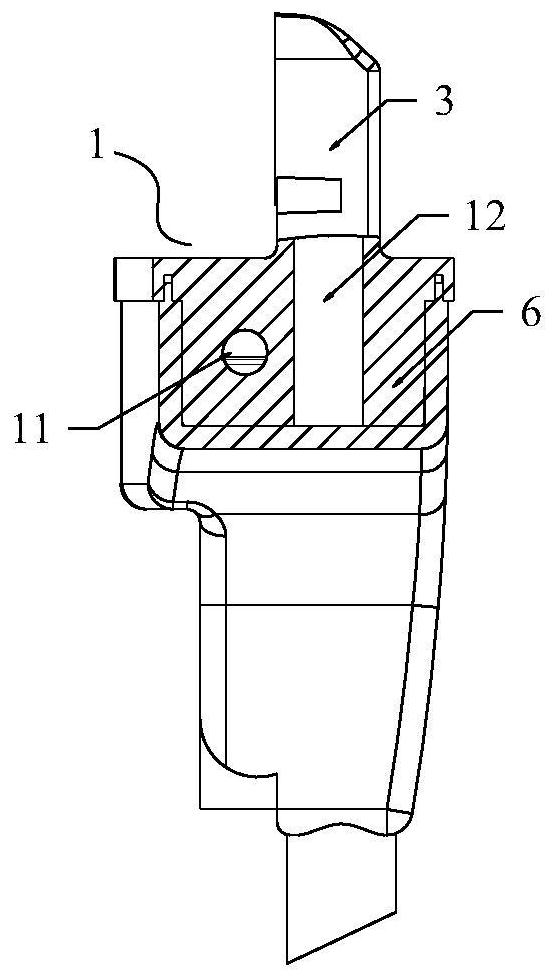

[0031] A suction muffler chamber with a buffer device, see Figure 1-6 , including an upper shell and a lower shell, the upper shell is closed on the lower shell to form a complete shell 1, the side wall of the shell 1 is provided with an air intake pipe 2, and the cross section of the air intake pipe 2 is It is "L" shape, the length of the horizontal section of the air intake pipe 2 is 8-12 mm, the length of the vertical section of the air intake pipe 2 is 24 mm, the top center of the housing 1 is provided with an air outlet pipe 3, and the housing 1 is provided with at least one partition to divide the inner cavity of the housing 1 into a plurality of isolated anechoic chambers. The housing 1 and the partition are made of PBT plastic.

[0032] The anechoic chamber is provided with a buffer fan blade 4, and the buffer fan blade 4 is rotatably matched with the inner wall of the housing 1; specifically, see figure 2 , the inner wall of the housing 1 is fixed with a bearing s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com