Chip-level vacuum sealed electrostatic galvanometer

A vacuum-sealed, electrostatic technology, applied in the field of vibrating mirrors and electrostatic vibrating mirrors, can solve the problems of increased module volume, decreased packaging vacuum degree, and increased noise level, so as to expand the application field, reduce driving requirements, and reduce The effect of energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

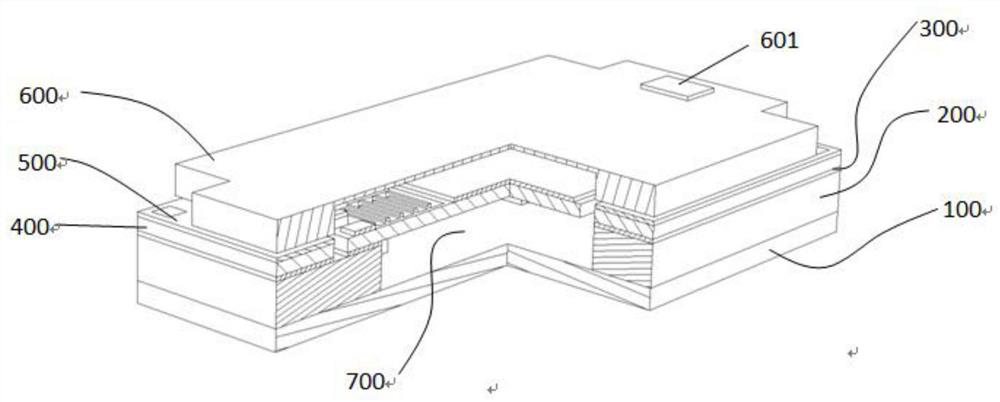

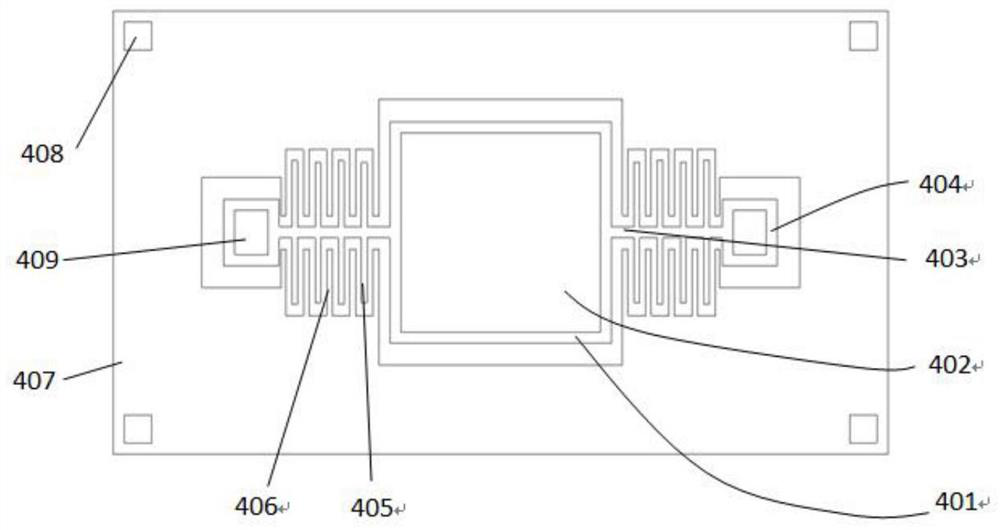

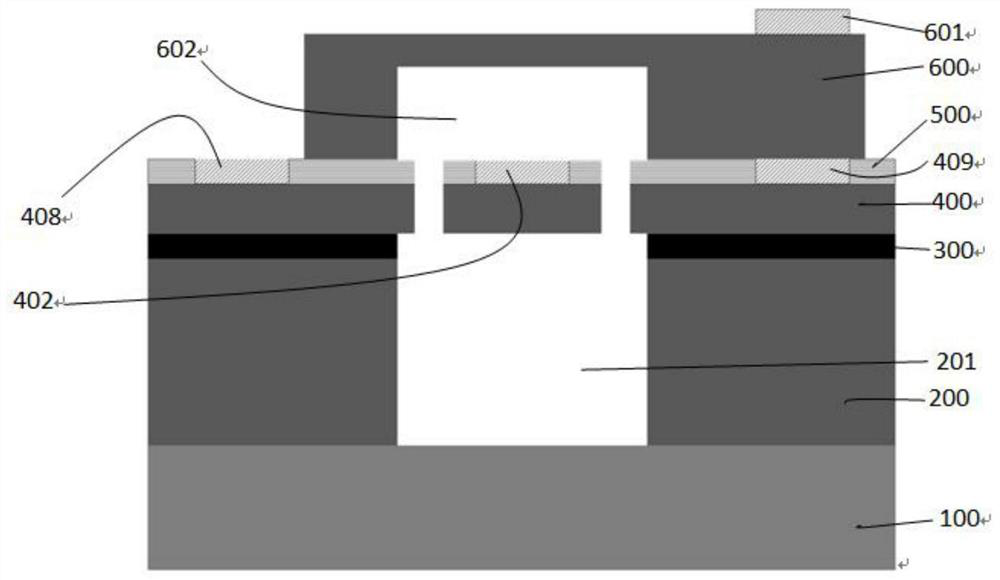

[0045] Such as figure 1 , 2 , a partial cross-sectional view of a vacuum-sealed single-axis galvanometer, which is composed of a substrate, a back cavity plate, an insulating layer, a structural layer, and a front cavity plate that are sequentially stacked and connected from bottom to top. The structural layer includes a mirror body, a mirror surface, a rotating shaft, an anchor body, a movable comb, a fixed comb, a pad and a fixed frame. The mirror surface is a thin layer of gold covering the upper surface of the mirror body, with a thickness of 100nm. The substrate, the back cavity plate, the insulating layer, the fixed frame of the structural layer and the front cavity plate are sequentially connected to form a closed cavity, and the reflector surface, reflector body, rotating shaft, anchor body, movable comb teeth and fixed comb teeth are all located in the closed cavity. inside the cavity.

[0046] Such as image 3 , the ground pad 409 communicates with the top pad 60...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com