Brushless motor base structure and brushless motor

A technology for brushless motors and fixed bases, which is applied in the direction of structural connections, electrical components, electromechanical devices, etc., can solve the problems of increasing the space occupied by the axial direction of the motor, poor wrapping and supporting stability, and insufficient flexibility of the brushless motor. Good and other problems, to achieve the effect of improving stability, facilitating assembly and connection, and facilitating fixation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

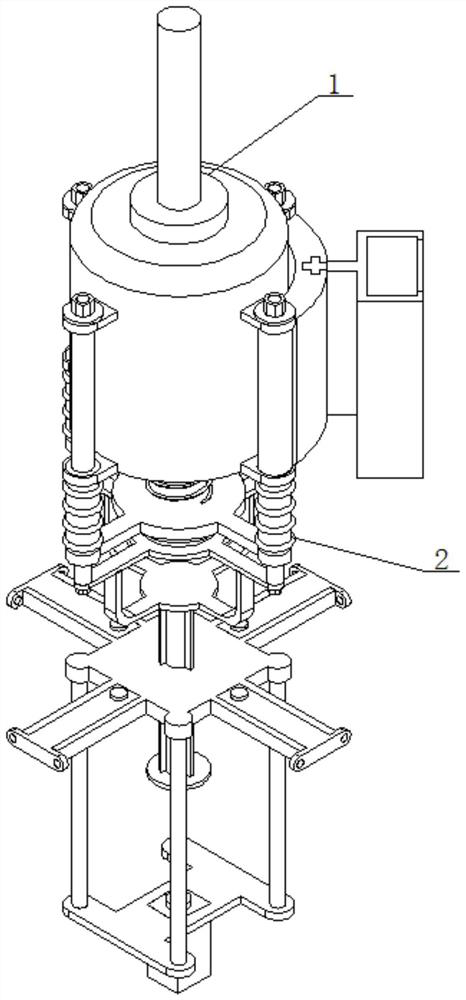

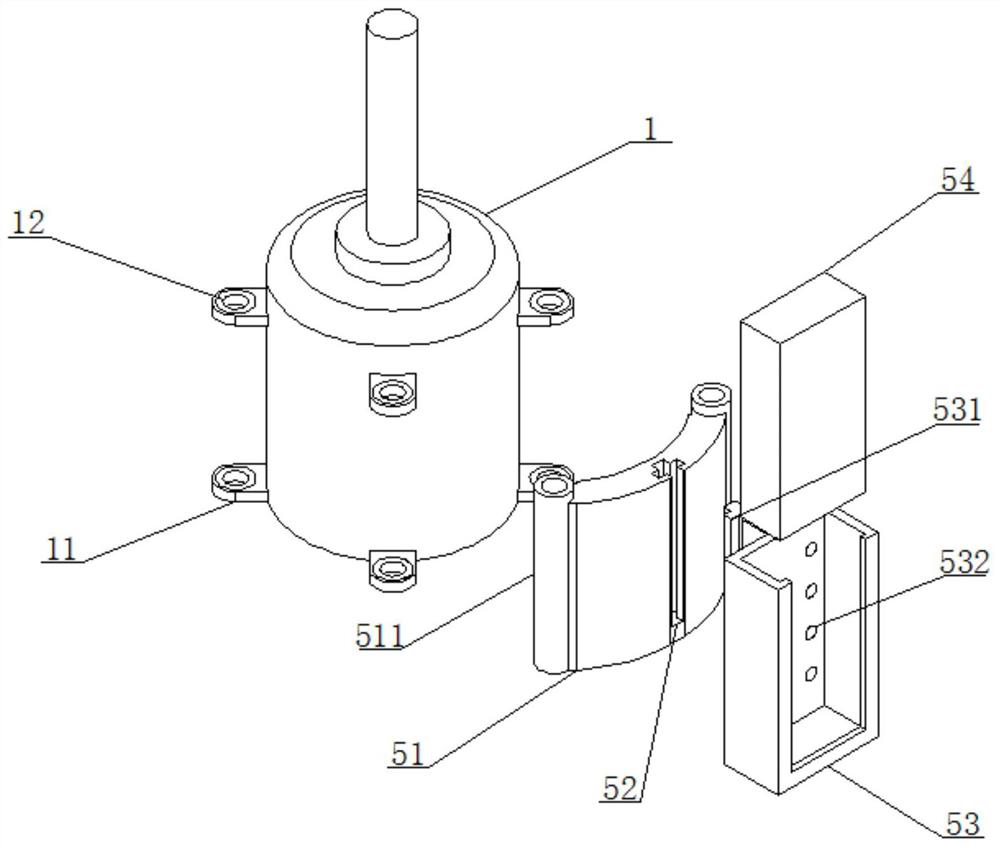

[0050] See figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 with Figure 8 As shown, a brushless motor base structure and a brushless motor comprising a brushless motor body 1, two ends of the brushless motor body 1 protective housing have a positioning aperture plate 11, and the positioning hole plate 11 is brushless The protective outer casing circumferential direction of the motor body 1 is uniformly disposed, and the rubber ring 12 is bonded in the through hole of the positioning orifice plate 11, further comprising

[0051] The damping structure 2, the damper structure 2 is provided on one side where the brushless motor body 1 is away from the output terminal, and the damper structure 2 is mounted on a portion of the brushless motor body 1 mounted on the brushless motor body 1. 11. The damper structure 2 includes a mounting plate 21, a rubber disk 22, and a pressure plate 23, and the mounting plate 213 is perpendicularly welded to the finisher 214, and...

Embodiment 2

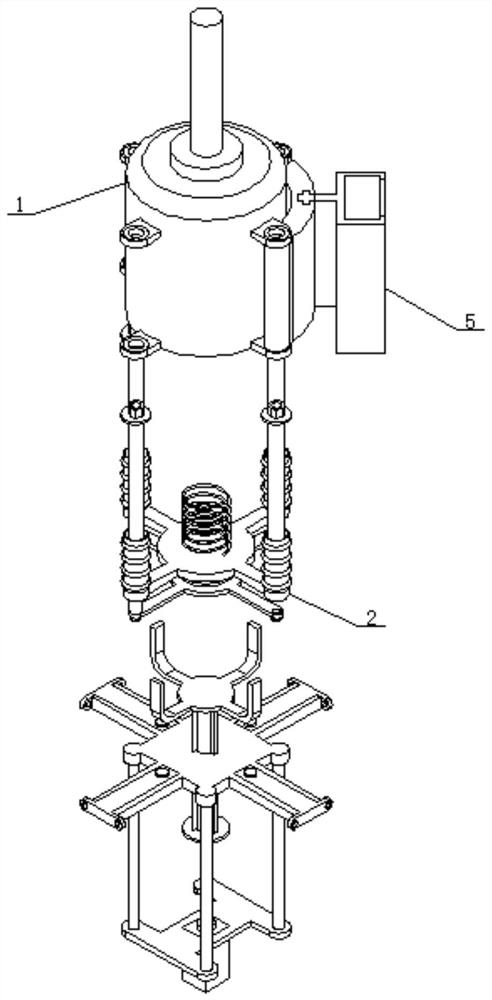

[0056] See Figure 9 , Figure 10 , Figure 11 with Figure 12 As shown, a brushless motor base structure and a brushless motor comprising a brushless motor body 1, two ends of the brushless motor body 1 protective housing have a positioning aperture plate 11, and the positioning hole plate 11 is brushless The protective outer casing circumferential direction of the motor body 1 is uniformly disposed, and the rubber ring 12 is bonded in the through hole of the positioning orifice plate 11, further comprising

[0057]The damping structure 2, the damper structure 2 is provided on one side where the brushless motor body 1 is away from the output terminal, and the damper structure 2 is mounted on a portion of the brushless motor body 1 mounted on the brushless motor body 1. 11. The damper structure 2 includes a mounting plate 21, a rubber disk 22, and a pressure plate 23, and the mounting plate 213 is perpendicularly welded to the finisher 214, and the bottom surface of the mounting plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com