Sugarcane field seed stem manufacturing method

A production method and technology of sugarcane, applied in planting methods, sugarcane cultivation, seed and rhizome treatment, etc., can solve the problems of laborious movement of soaking baskets, error-prone, increased shipping costs, etc., to achieve reduced transportation and storage costs, better The effect of fixing and exerting force and avoiding transportation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

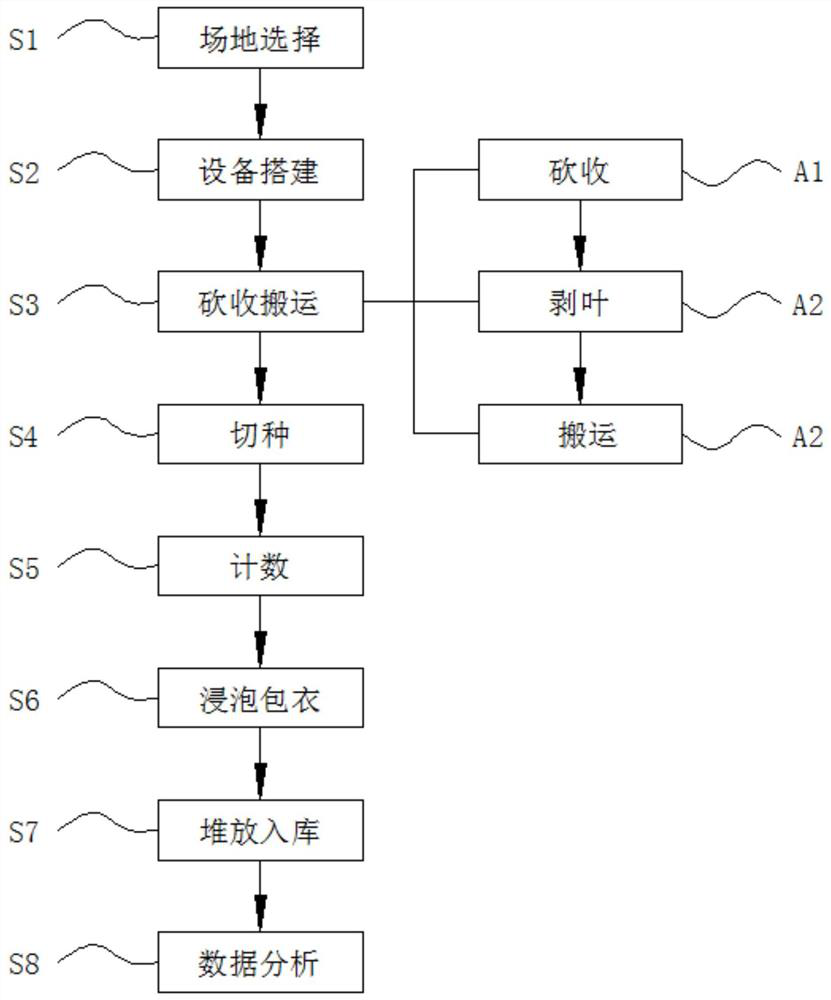

[0058] Such as figure 1 As shown, this embodiment provides a kind of sugarcane field seed stem making method, mainly comprises the following steps:

[0059] S1: Site selection. In the sugarcane good breeding base, according to the maturity time sequence of sugarcane varieties in different planting fields, determine the harvesting sequence of different planting fields, and select equipment in the field to build a site nearby. Harvest early-maturing varieties first, and then harvest mid-late-maturing varieties ; Harvest autumn cane and perennial root cane first, then harvest winter and spring cane planting, and the cane fields with permanent roots will be harvested after mid-January; if it is not convenient to build equipment nearby, you can implement the plan according to the overall path to each sugarcane field , with the least total distance and convenient transportation;

[0060] S2: For equipment construction, first remove the sundries in the construction site to make the ...

Embodiment 2

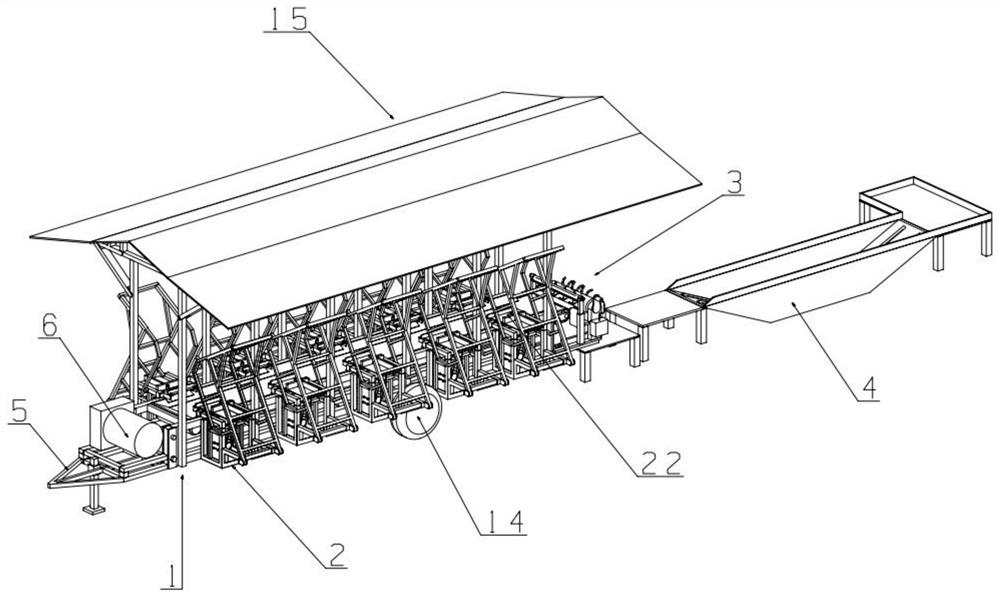

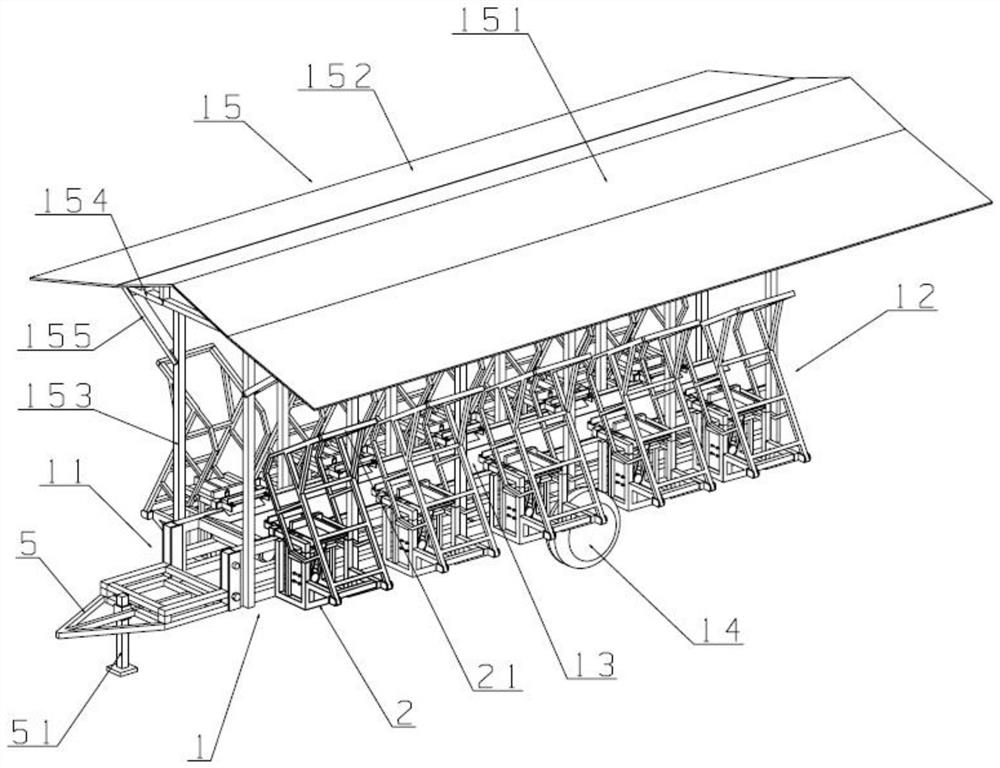

[0071] Such as figure 2 As shown in the figure, this embodiment provides a mobile seed stem production equipment, which is used to realize a method for making sugarcane field seed stems in the above embodiment, including: a mobile frame 1, a feeding end 11, a feeding end End 12, main conveyor belt 13, wheels 14, cover shed 15, middle cover 151, side cover 152, middle cover frame 153, side cover frame 154, support rod 155, seed cutting machine 2, raw material frame 21, seed cutting frame 22 , slide rail 23, cane cutting board 24, cane blocking bar 25, saw blade 26, cane cutting motor 27, protection box 28, positioning hole 281, box opening 29, length adjustment plate 210, guide plate 211, counting and seeding device 3 , counting roller 31, rake teeth 32, counting conveyor belt 33, pendulum assembly 34, guiding cane plate 341, guiding cane groove 342, passing hole 343, pressing cane plate 344, telescopic rod 345, splint seat 346, loading table 35, Infrared receiver 36, infrare...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com