Paint brushing device and method for deformed grooves of iron core

An iron core and deformity technology, which is applied to the field of painting devices for iron core deformity grooves, can solve the problems of complex process, large land occupation and high cost, and achieve the effects of simple process, low cost and small floor space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

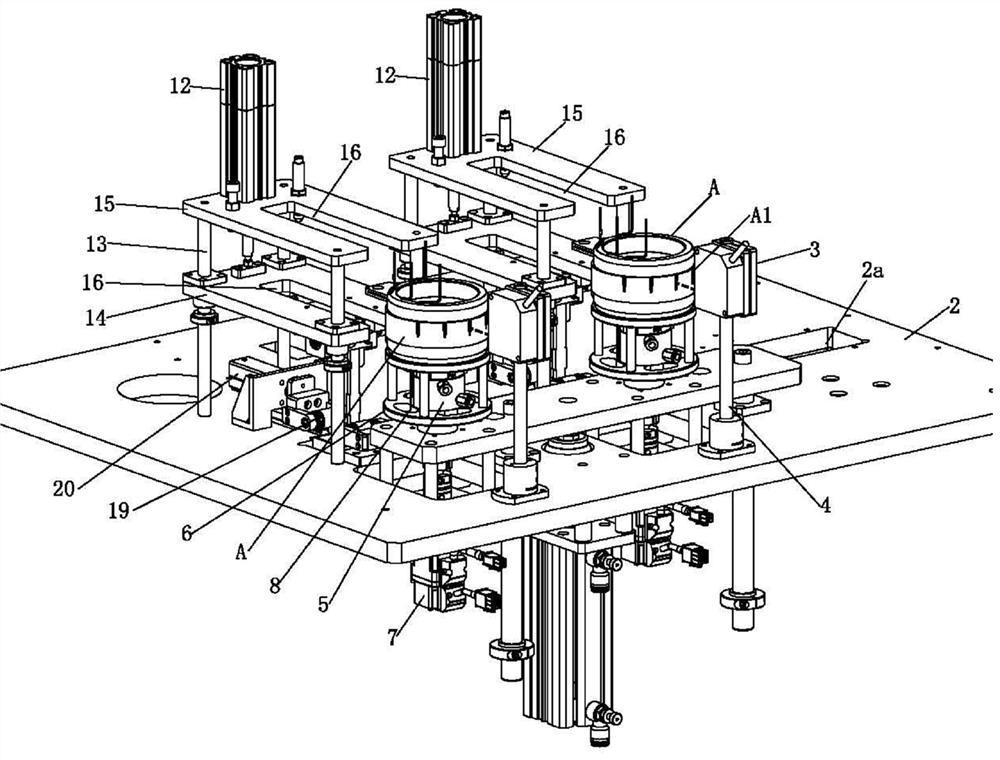

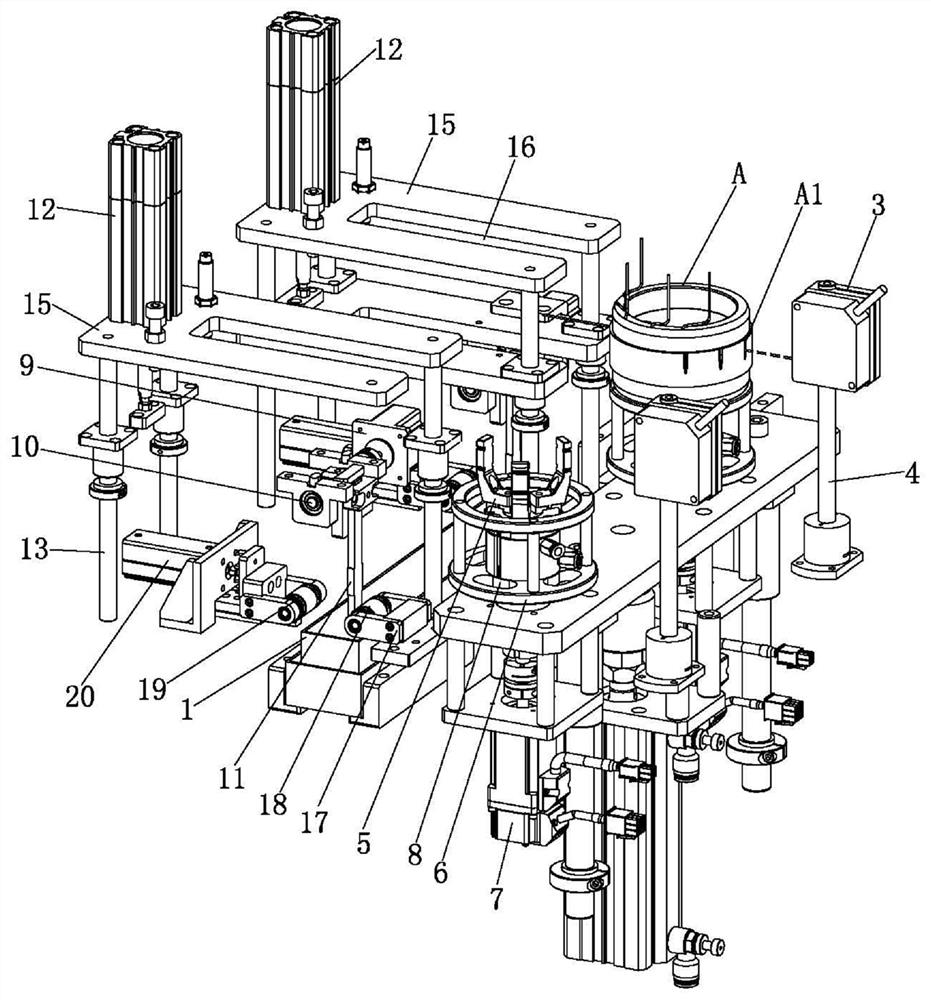

[0048] Combine below Figure 1 to Figure 2 The present invention will be described.

[0049] The painting device for deformed iron core slots of the present invention includes a paint mechanism for accommodating paint, a detection mechanism, a controller (not shown in the figure), a positioning index mechanism, and a rotating paint mechanism. The relationship between is described in detail:

[0050] The paint mechanism includes a paint container 1 and a support plate 2. The support plate 2 is provided with a through hole 2a. Plate 2 is fixedly connected. In addition, the detection mechanism, the controller, the positioning and indexing mechanism, and the rotating painting mechanism are all connected to the support plate 2 .

[0051] The detection mechanism detects the deformed groove A1 on the iron core A, and the controller is electrically connected with the detection mechanism to obtain the detection signal provided by the detection mechanism. The detection mechanism incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com