Laser cutting machine tool workbench facilitating material taking

A laser cutting and workbench technology, applied in laser welding equipment, manufacturing tools, metal processing equipment, etc., can solve the problems of increasing production costs, wasting time, and difficulty in manually picking up distance workpieces, and achieving the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

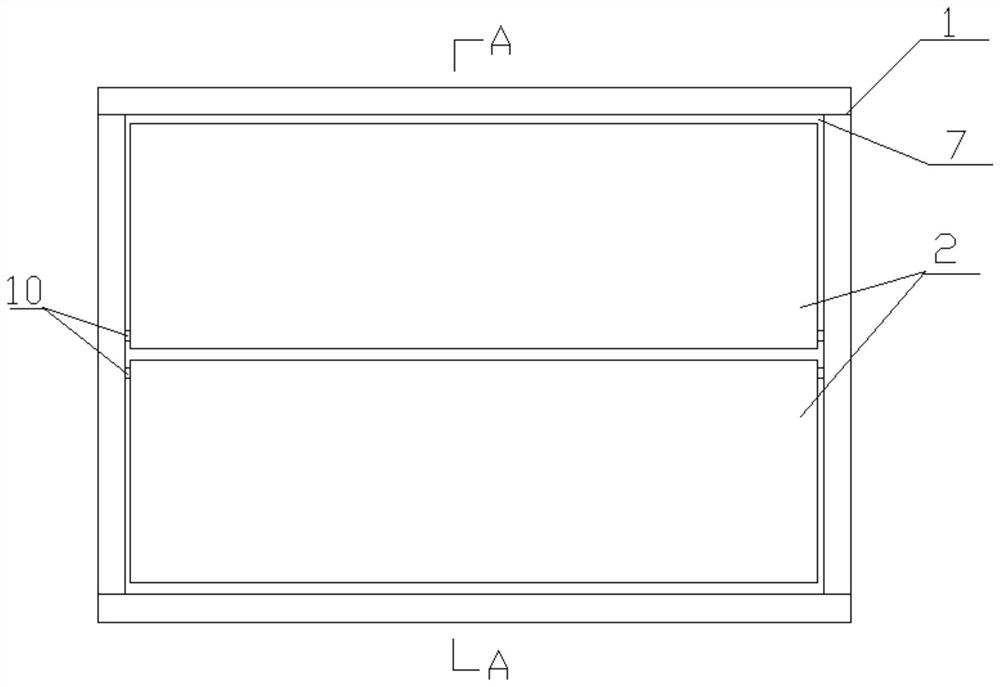

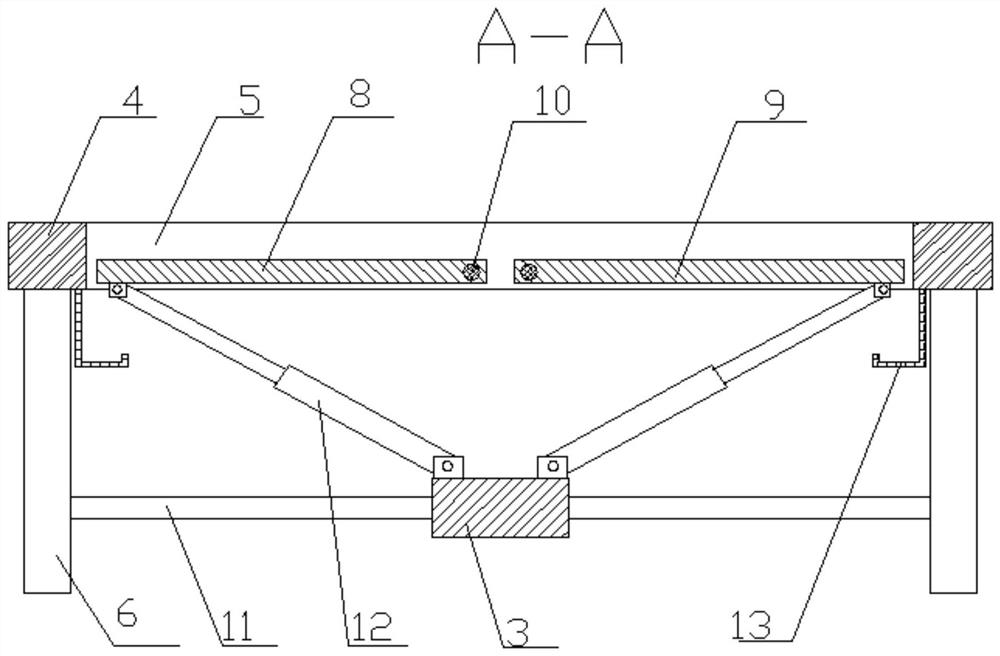

[0014] Example: such as figure 1 and figure 2 As shown, a laser cutting machine tool workbench that is convenient for retrieving materials includes a bed 1, a workbench 2 and a support plate 3, the bed 1 includes a beam 4, a longitudinal beam 5 and a bed leg 6, and the beam 4 and the longitudinal beam 5 are respectively There are two, the two ends of the two crossbeams 4 are fixedly connected with a longitudinal beam 5 respectively, and the lower sides of the two ends of each crossbeam 4 are respectively fixedly connected with a bed leg 6, and the two crossbeams 4 and the two longitudinal beams 5 form a The bed frame 7 and the workbench 2 are arranged in the bed frame 7. The workbench 2 includes a first workbench 8 and a second workbench 9. The sides of the first workbench 8 and the second workbench 9 away from the beam 4 respectively pass through a rotating shaft 10 Connected with the longitudinal beam 5, the lower sides of the two longitudinal bed legs 6 are respectively f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com