Lining double-layer oil tank structure and transformation method of single-layer oil tank

A double-layer oil tank and inner lining technology is applied in the field of transformation of inner-lined double-layer oil tank structure and single-layer oil tank to achieve the effect of solving the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] The transformation method of a single-layer oil tank specifically includes the following steps:

[0059] The first step is to clean the operation well and block the oil inlet and outlet pipelines;

[0060] The second step is to clean up the residual oil and clean the oil tank;

[0061] The third step is to replace the air in the tank and monitor the combustible gas;

[0062] The fourth step is to sandblast the inner surface of the oil tank to remove rust, and the rust removal level should not be lower than SA2.5;

[0063] The fifth step is to check the thickness of the steel tank body, the average thickness should not be less than 4mm;

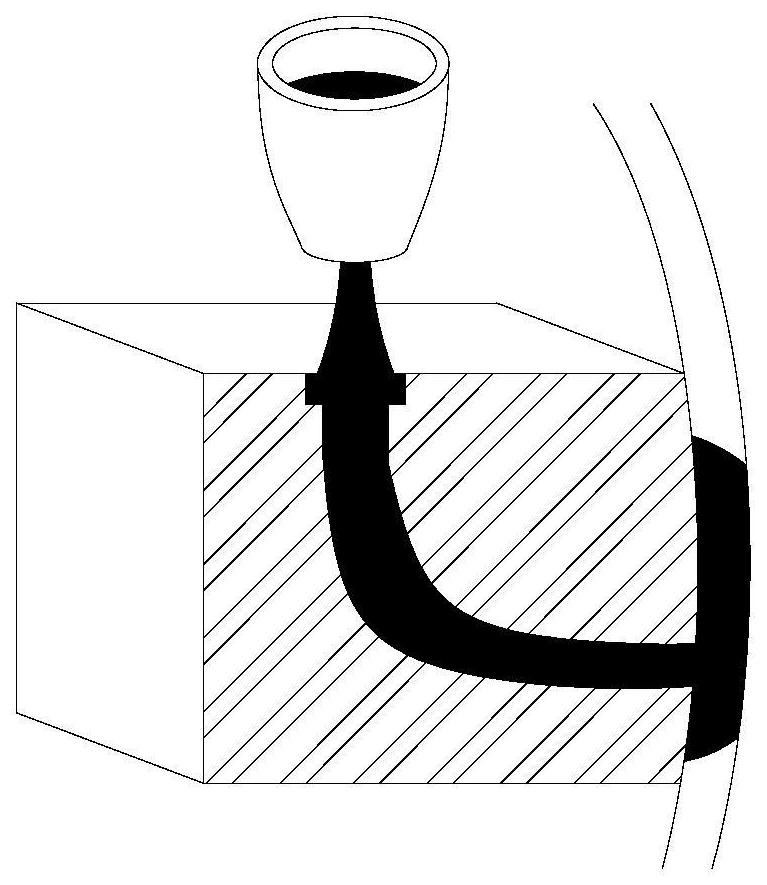

[0064] The sixth step is to corrode and perforate the steel tank body according to the aluminothermic method. figure 1 Repair as shown;

[0065] The seventh step is to coat the inner wall of the oil tank with a primer within 8 hours after the derusting is completed. The bonding strength between the coating and the steel tank should...

Embodiment 2

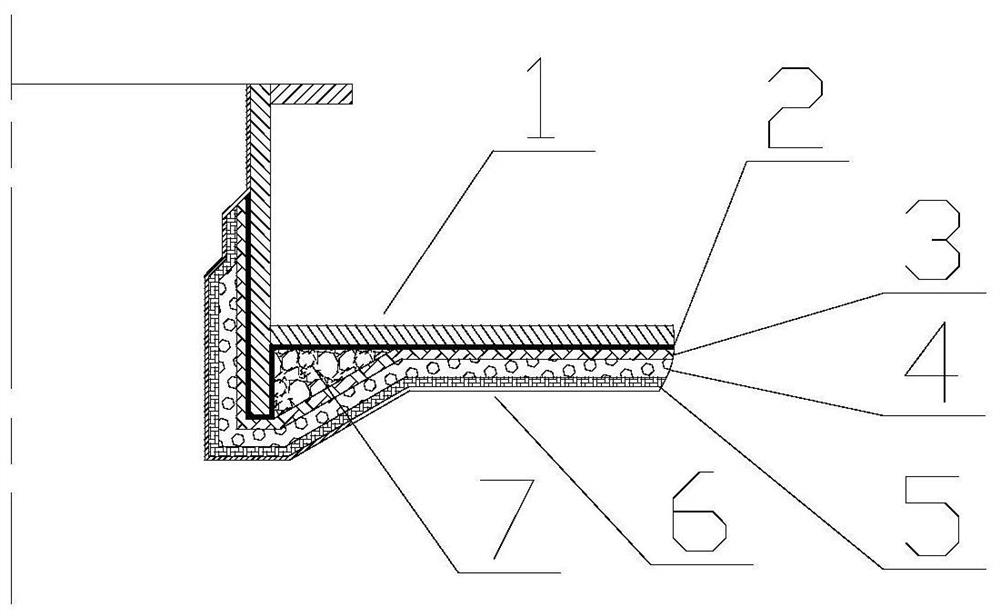

[0074] The connection between the ring rib and the triangular support should be handled in the following way:

[0075] The inner layer of the inner lining is covered outwardly and the outer layer of the inner lining is covered inward at the same time, and the middle layer of the inner lining is wrapped to form a complete and sealed middle layer of the inner lining structure.

Embodiment 3

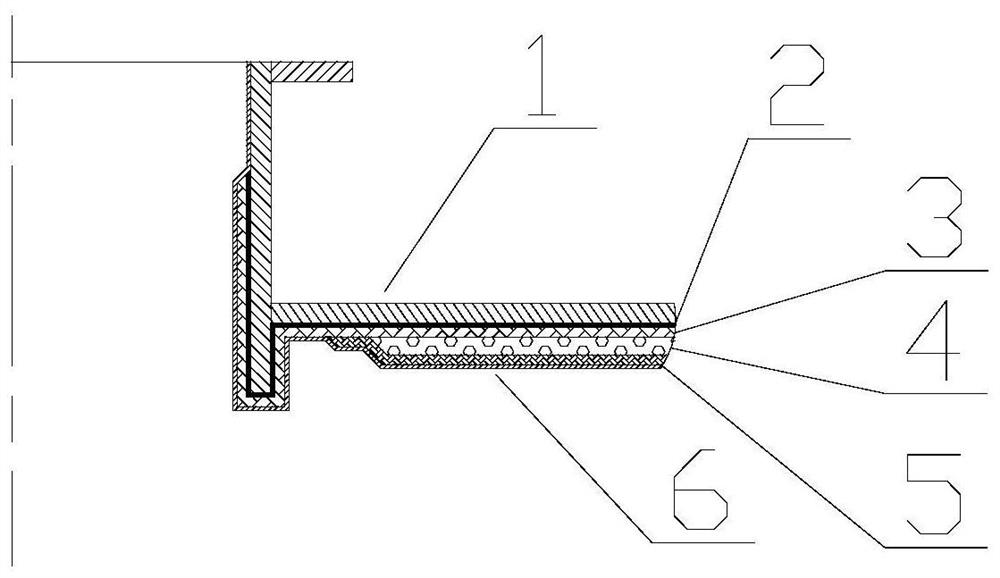

[0077] The present invention relates to a lined double-layer oil tank structure, which includes a single-layer steel tank body 1 and an inner lining structure, and the inner lining structure includes a primer layer 2 arranged inwardly from the inner wall of the single-layer steel tank, The outer lining layer 3, the inner lining layer 4, the inner lining layer 5 and the static conductive layer 6 are provided with monitoring ports, manholes and lifting lugs on the single-layer tank body.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com