Novel elevator landing door plate assembly

A layer door panel and door panel technology, applied in the field of elevators, can solve the problems of heavy overall weight, heavy pollution, and insufficient environmental protection, and achieve good corrosion resistance such as acid, alkali, and salt, light weight, and the effect of improving experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

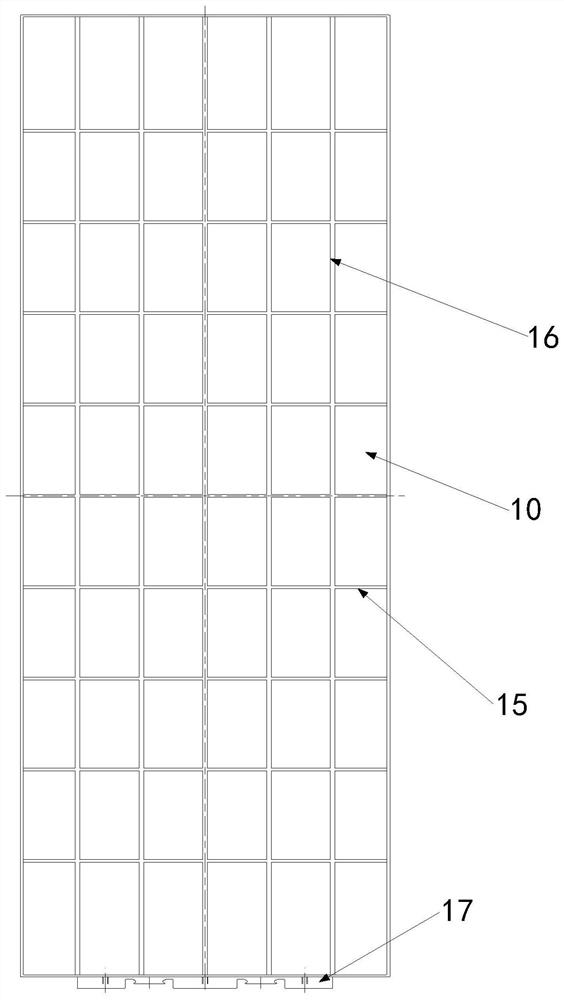

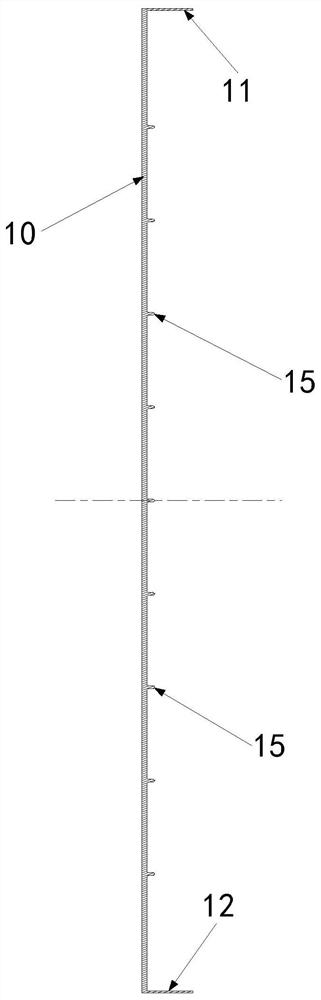

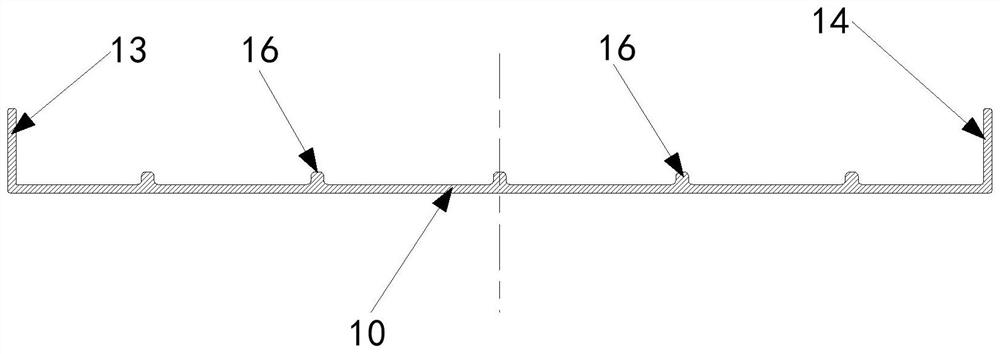

[0021] Such as Figure 1-5 As shown, the novel elevator floor door panel assembly includes a door panel body 10, an upper baffle 11, a lower baffle 12, a left baffle 13, a right baffle 14, a plurality of first reinforcing ribs 15, a plurality of second reinforcing ribs 16, Door panel guide shoe plate 17 and a plurality of door panel guide shoes 18.

[0022] The door panel body 10 is rectangular.

[0023] The upper baffle 11 is vertically arranged on the top of the door panel body 10 .

[0024] The lower baffle 12 is vertically arranged on the bottom of the door panel body 10 .

[0025] The left baffle 13 is vertically arranged on the left side of the door panel body 10 .

[0026] The right baffle 14 is vertically arranged on the right side of the door panel body 10 .

[0027] In this embodiment, the door body 10 , the upper baffle 11 , the lower baffle 12 , the left baffle 13 and the right baffle 14 form a rectangular receiving space.

[0028] A plurality of first reinfor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com