Sludge dewatering mechanism

A sludge dehydration and dehydration device technology, applied in water/sludge/sewage treatment, sludge treatment, dehydration/drying/thickened sludge treatment, etc., can solve environmental impact and other problems, achieve dehydration cost reduction, and reasonable design , The effect of improving the dehydration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

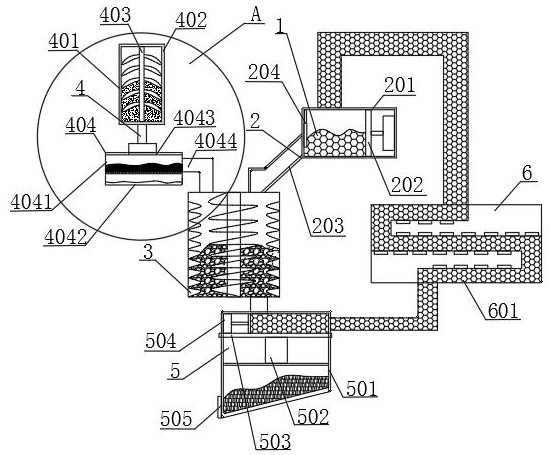

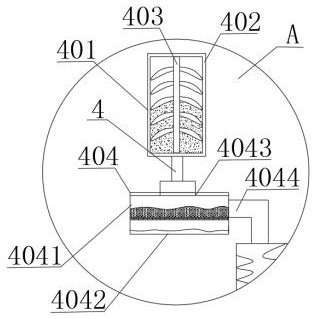

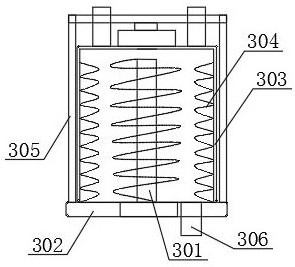

[0031] Refer to attached Figure 1-3 , a sludge dewatering mechanism, including a plurality of superabsorbent monomers 1, the superabsorbent monomers 1 are located in a discharge box 2, and one side of the discharge box 2 is connected to a mixing and dehydrating device 3, and the mixing and dehydrating device 3 The other side is provided with a coarse dehydration device 4.

[0032] The superabsorbent monomer 1 includes a superabsorbent resin, the superabsorbent resin is a sphere, and a plurality of small water-absorbing ports are opened on the outside of the sphere, and the superabsorbent water resin is a high-water absorber with a certain degree of crosslinking. Polymer, it can quickly absorb water hundreds of times larger than its own weight to form a gel. Good absorption locks in moisture, and the spherical structure with holes is more conducive to moisture absorption.

[0033] The discharge box 2 includes a box body 201, one side of the box body 201 is fixedly connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com