Polycarboxylate water reducer composite material and use method thereof, and concrete

A technology of water reducing agent and polycarboxylic acid, which is applied in the field of water reducing agent, can solve the problems of poor early strength performance and achieve the effect of improving early strength performance and maintaining water reducing function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

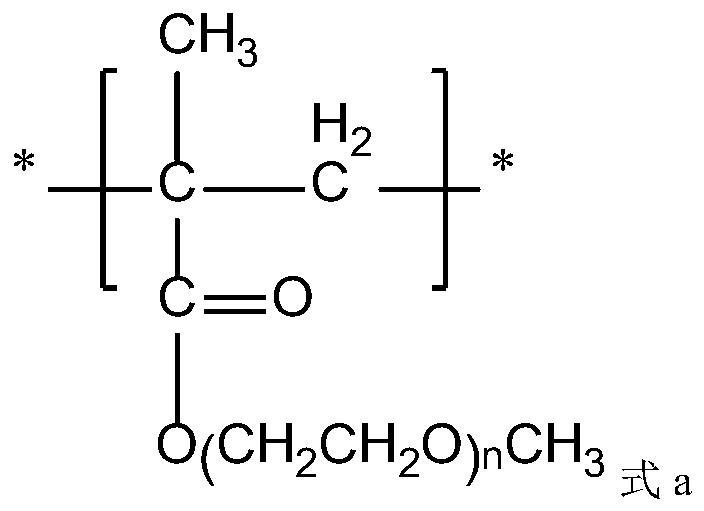

[0061] Weigh 250g of MPEG-type polycarboxylate high-performance water reducer, prepare the water reducer as an aqueous solution (concentration: 75wt%), then add 5g of magnesium tourmaline powder to the solution to obtain the mixed material a, and then mix the material Mix with 425 portland cement, sand, stones and water (mass ratio 350:792:1008:200) to obtain concrete, wherein the mass ratio of material a to the solid phase in the concrete is 0.3wt%.

Embodiment 2

[0063] Weigh 250g of MPEG-type polycarboxylate high-performance water-reducer, prepare the water-reducer as an aqueous solution (concentration is 75wt%), then add calcium magnesium tourmaline powder 8g to the solution to obtain the mixed material a, and then add the The material is mixed with 425 Portland cement, sand, stones and water (mass ratio is 350:792:1008:200) to obtain concrete, wherein the mass ratio of material a to the solid phase in the concrete is 0.25wt%.

Embodiment 3

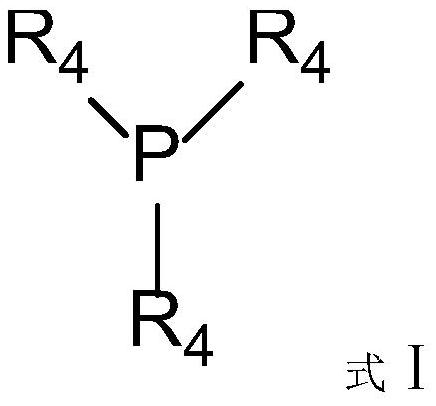

[0065] Weigh 250g of MPEG-type polycarboxylate high-performance water reducer, prepare the water reducer as an aqueous solution (concentration is 75wt%), then add 5g of trivinylphosphine to the solution to obtain the mixed material a, and then add the The material is mixed with 425 Portland cement, sand, stones and water (mass ratio is 350:792:1008:200) to obtain concrete, wherein the mass ratio of material a to the solid phase in the concrete is 0.3wt%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com