High-dielectric-property self-healing polyurethane composite material as well as preparation method and braking application thereof

A composite material, self-healing technology, applied in piezoelectric effect/electrostrictive or magnetostrictive motors, generators/motors, electrical components, etc., can solve restrictive development, dielectric elastomer burning, damage, etc. problems, to achieve the effect of improving dielectric properties, high electromechanical stability, and improving braking performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

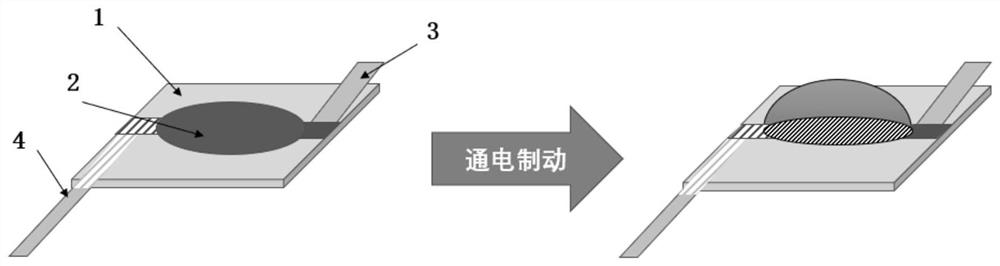

[0030] Such as figure 1 Shown is the basic structure of the dielectric elastomer microbrake of the present invention, which is a capacitive structure consisting of a dielectric layer in the middle and flexible electrodes on both sides of the upper and lower sides. The material of the flexible electrodes is conductive carbon grease, and the two poles of the flexible electrodes pass through the The conductive copper foil is connected to the positive and negative electrodes of the high-voltage power supply; the dielectric layer is self-healing polyurethane (PU-UPy) filled with Au / TiC composite filler, wherein the weight content of Au / TiC is 0.02wt%, and the thickness is 100 μm. A method for preparing a dielectric elastomer microbrake with high dielectric performance self-healing performance, comprising the steps of:

[0031] ① Stir PTMEG at 120°C for 2 hours under vacuum, cool to 70°C after removing water;

[0032] ② Add HDI to the flask and stir for 1 hour, then add DBTDL and h...

Embodiment example 2

[0040] Such as figure 1 Shown is the basic structure of the dielectric elastomer microbrake of the present invention, which is a capacitive structure consisting of a dielectric layer in the middle and flexible electrodes on both sides of the upper and lower sides. The electrode material is conductive carbon grease, and the two poles are respectively connected by conductive copper foil. The positive and negative electrodes of the high-voltage power supply; the dielectric layer is self-healing polyurethane (PU-UPy) filled with Au / TiC composite filler, wherein the weight content of Au / TiC is 0.04wt, and the thickness is 100 μm. A method for preparing a dielectric elastomer microbrake with high dielectric performance self-healing performance, comprising the steps of:

[0041] ① Stir PTMEG at 120°C for 2 hours under vacuum, cool to 70°C after removing water;

[0042] ② Add HDI to the flask and stir for 1 hour, then add DBTDL (catalyst) and heat up to 80°C and stir for 3 hours;

...

Embodiment example 3

[0050] Such as figure 1 Shown is the basic structure of the dielectric elastomer microbrake of the present invention, which is a capacitive structure consisting of a dielectric layer in the middle and flexible electrodes on both sides of the upper and lower sides. The electrode material is conductive carbon grease, and the two poles are respectively connected by conductive copper foil. The positive and negative electrodes of the high-voltage power supply; the dielectric layer is a self-healing polyurethane (PU-UPy) filled with Au / TiC composite filler, wherein the weight content of Au / TiC is 0.06wt%, and the thickness is 100 μm. A method for preparing a dielectric elastomer microbrake with high dielectric performance self-healing performance, comprising the steps of:

[0051] ① Stir PTMEG at 120°C for 2 hours under vacuum, cool to 70°C after removing water;

[0052] ② Add HDI to the flask and stir for 1 hour, then add DBTDL and heat up to 80°C and stir for 3 hours;

[0053] ③...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com