Novel horizontal and longitudinal connecting system for three-split type steel box girder

A horizontal and vertical steel box girder technology, applied in bridges, bridge materials, bridge construction, etc., can solve the problems of low transmission efficiency, achieve the effects of reducing the impact of eddy vibration, reasonable structure, and improving the aesthetic feeling of overlooking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below, the present invention is described in detail with reference to accompanying drawing and embodiment:

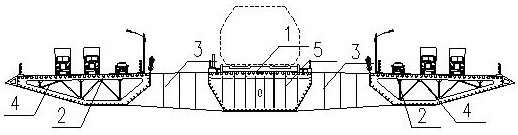

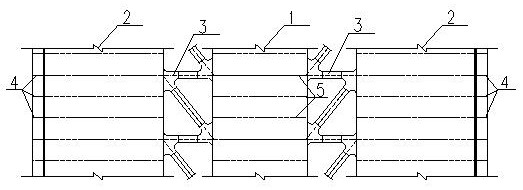

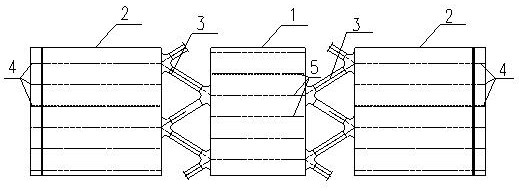

[0028] Such as Figure 1~5 As shown, a new horizontal longitudinal connection system for a three-part steel box girder, including a middle steel box girder 1 and side steel box girders 2 respectively placed on both sides thereof, the middle steel box girder 1 and the side steel box girder 2 is connected as a whole through the horizontal longitudinal connection system component 3, the horizontal longitudinal connection system component 3 is in a continuous bending shape, and the bending part of the horizontal longitudinal connection system component 3 is fixed to the middle steel box girder 1 / side steel box girder 2 .

[0029] The horizontal longitudinal connection system assembly 3 is composed of a plurality of connection units arranged between the middle steel box girder 1 and the side steel box girder 2 .

[0030] The connection unit includes a rear connectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com