Foam concrete expanded-base combined upper soil body light curing core-inserting pile treatment method

A technology of foam concrete and processing method, which is applied in the fields of soil protection, construction, and foundation structure engineering, etc. It can solve the problems of heavy weight, limited increase in the bearing capacity of rigid piles, and low strength of cement mixed soil, etc., and achieves light weight and good construction Simple, simple and convenient effect of cast-in-place construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

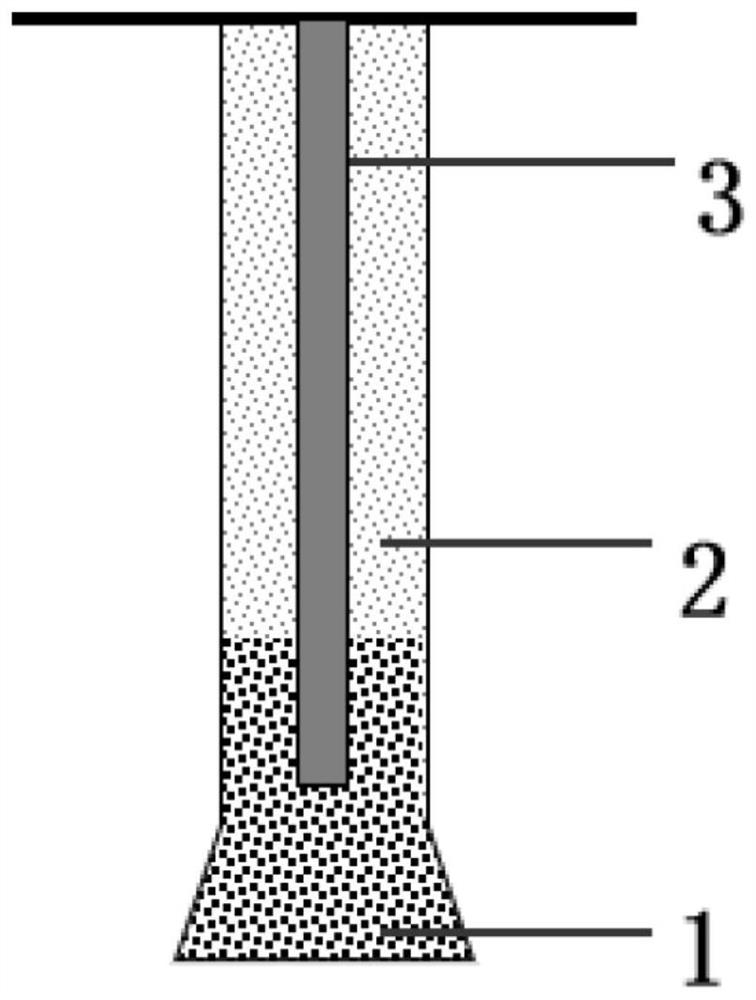

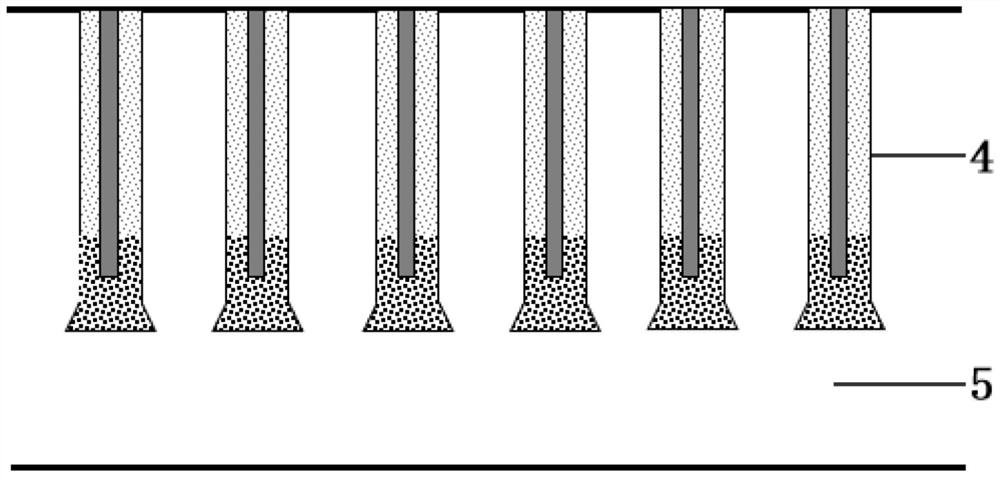

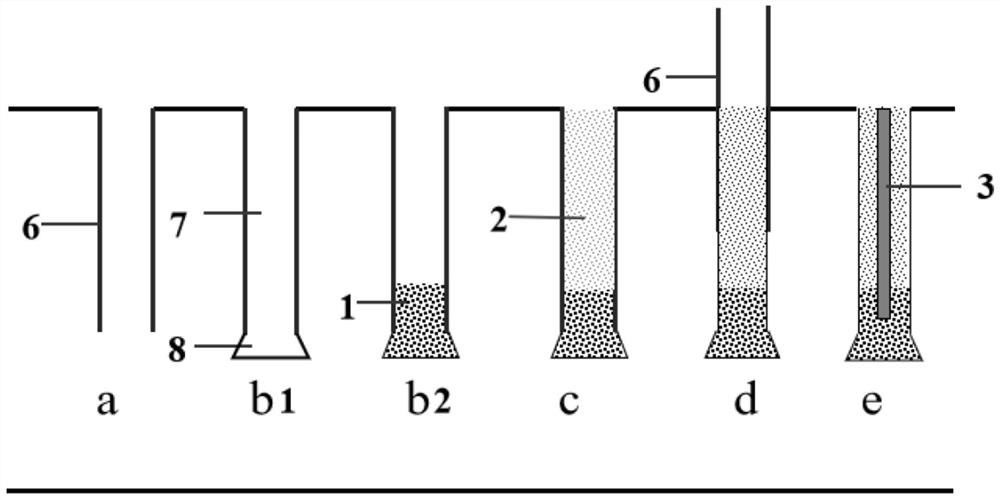

[0028] refer to Figure 1 ~ Figure 3 As shown, the foamed concrete bottom expansion in the first embodiment provided by the present invention is combined with the method for treating cored piles with light solidification of the upper soil, comprising the following steps:

[0029] 1) Drive the steel sleeve 6 into the soft soil foundation 5, then drill holes to take out the soil in the steel sleeve 6 to form the inner borehole 7, and drill the inner hole 7 with the reaming drill bit when the hole reaches the bottom Reaming is carried out at the bottom to form bottom reaming 8;

[0030] 2) Pouring the foamed concrete 1 in the steel sleeve 6 to the design elevation to form the bottom layer of foamed concrete 1 as the expansion layer;

[0031] 3) After the pouring of the bottom foam concrete 1 is completed, immediately pour the foam solidified soil 2 in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com