Sludge pumping equipment for river sewage treatment

A sewage treatment and river channel technology, applied in the direction of earth mover/shovel, mechanically driven excavator/dredger, construction, etc., can solve the problems of small extraction range, damage to the mouth of the mud pumping pipe, and low efficiency. To achieve the effect of improving practicability, reducing damage and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

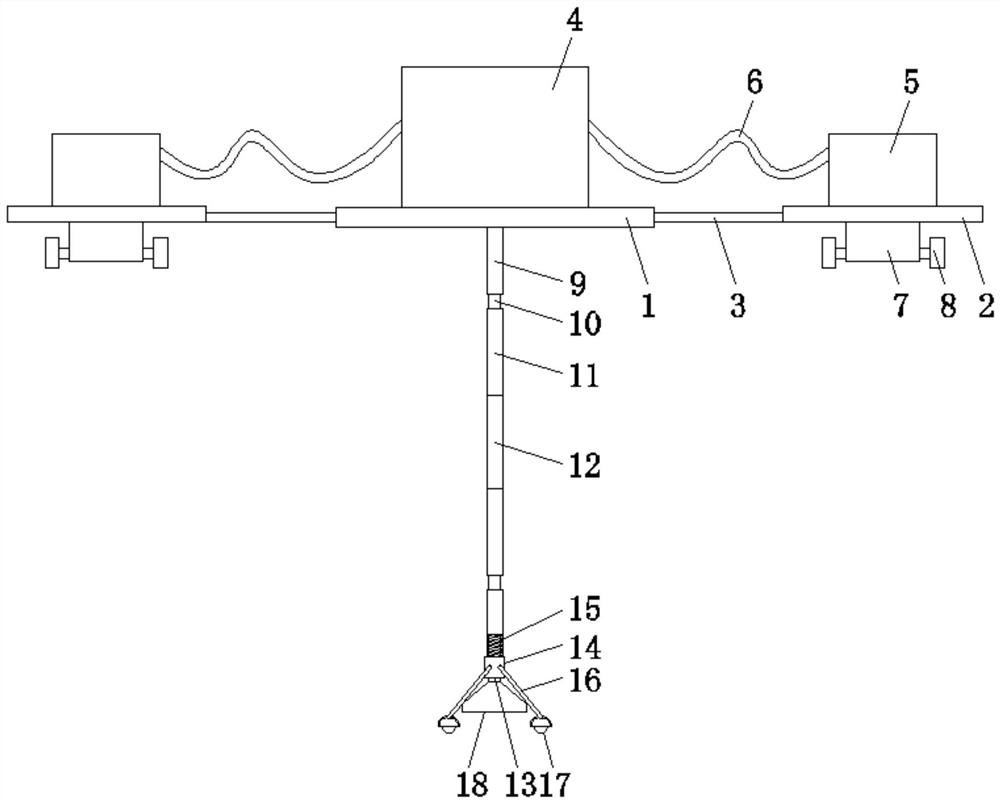

[0027] Such as figure 1 , Figure 3-5 As shown, a mud pumping equipment for river sewage treatment includes a first floating plate 1 and two second floating plates 2, the first floating plate 1 and the second floating plate 2 are connected by a connecting rod 3, and the second floating plate The bottom of the plate 2 is provided with a moving assembly, the first floating plate 1 is provided with a pump 4, and the second floating plate 2 is provided with a sludge tank 5. The pump 4 and the sludge tank 5 are connected through a connecting pipe 6. The first A mud pumping assembly is provided under the floating plate 1, and the pump 4 communicates with the mud pumping assembly;

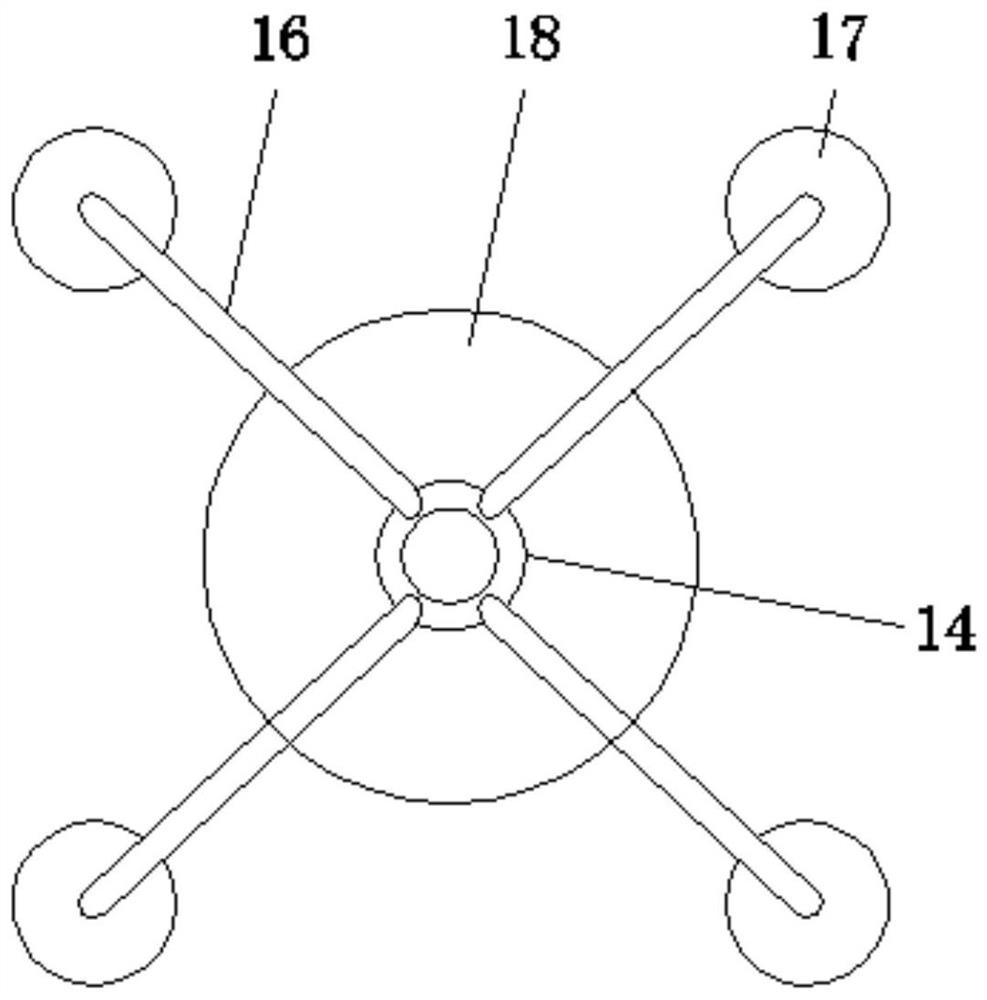

[0028] Described mud pumping assembly comprises conduction pipe 9 and mud pumping pipe 13, and mud pumping pipe 13 is communicated with pump 4 by conducting pipe 9, and the bottom end of mud pumping pipe 13 is provided with mud pumping port 18, and the top of mud pumping pipe 13 Extending into the insid...

Embodiment 2

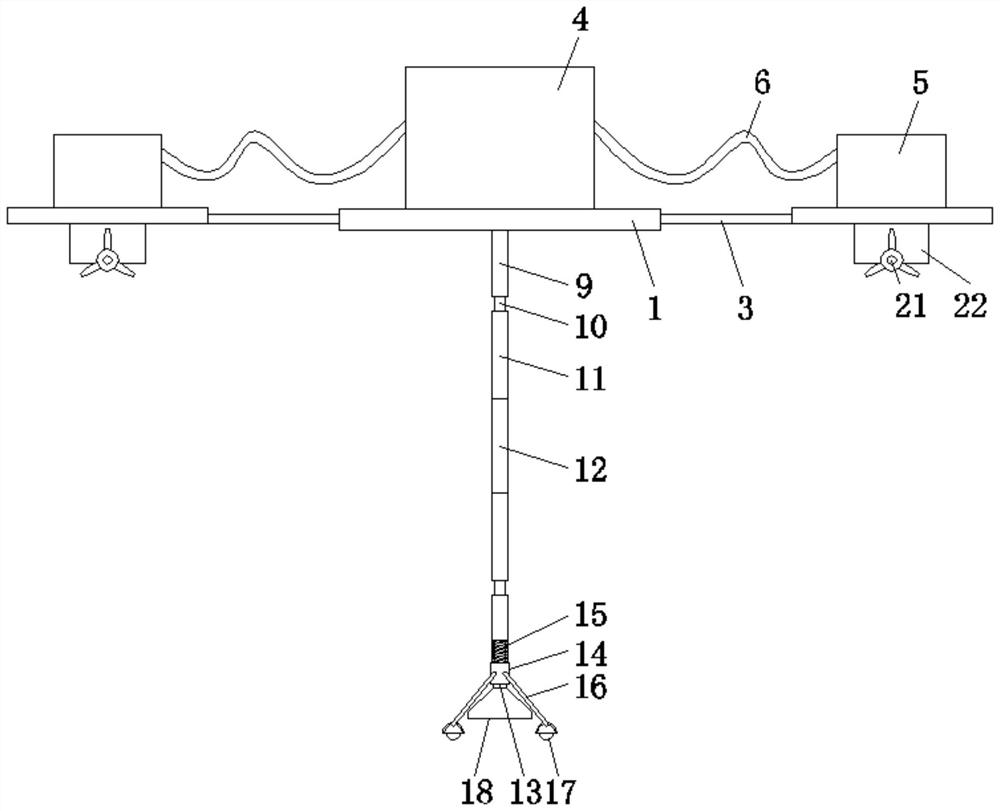

[0039] A mud pumping device for river sewage treatment, comprising a first floating plate 1 and two second floating plates 2, the first floating plate 1 and the second floating plate 2 are connected by a connecting rod 3, the second floating plate 2 There is a moving assembly at the bottom, a pump 4 is provided on the first floating plate 1, a sludge tank 5 is provided on the second floating plate 2, the pump 4 and the sludge tank 5 are connected through a connecting pipe 6, and the first floating plate 1 The bottom of the pump is provided with a mud pumping assembly, and the pump 4 communicates with the mud pumping assembly;

[0040] Described mud pumping assembly comprises conduction pipe 9 and mud pumping pipe 13, and mud pumping pipe 13 is communicated with pump 4 by conducting pipe 9, and the bottom end of mud pumping pipe 13 is provided with mud pumping port 18, and the top of mud pumping pipe 13 Extending into the inside of the conduction pipe 9, the mud pumping pipe 13...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com