Assembly type green building

A green building and prefabricated technology, applied in construction, building structure, water supply equipment, etc., can solve the problems of rain noise, reduced comfort, and large disadvantages, and achieve the effect of reducing noise and preventing blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

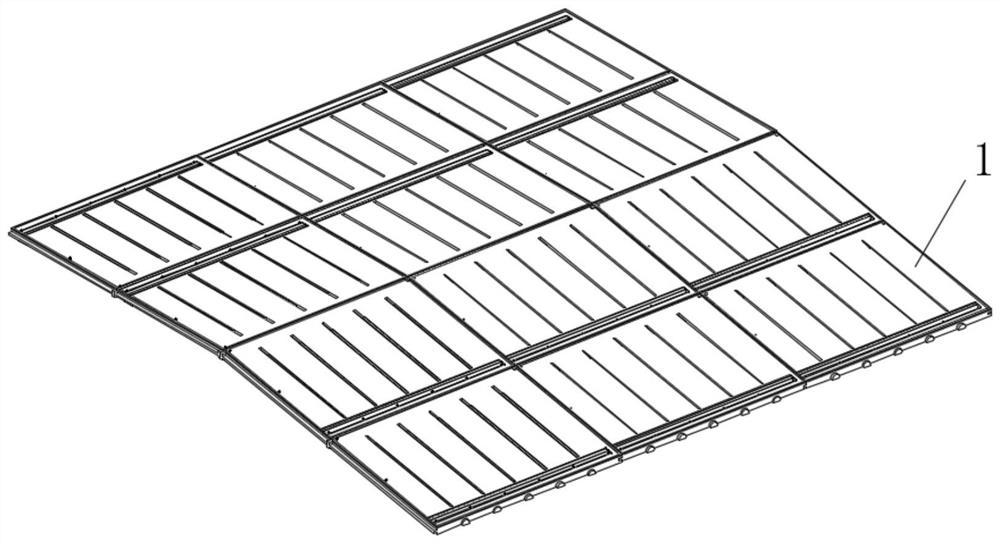

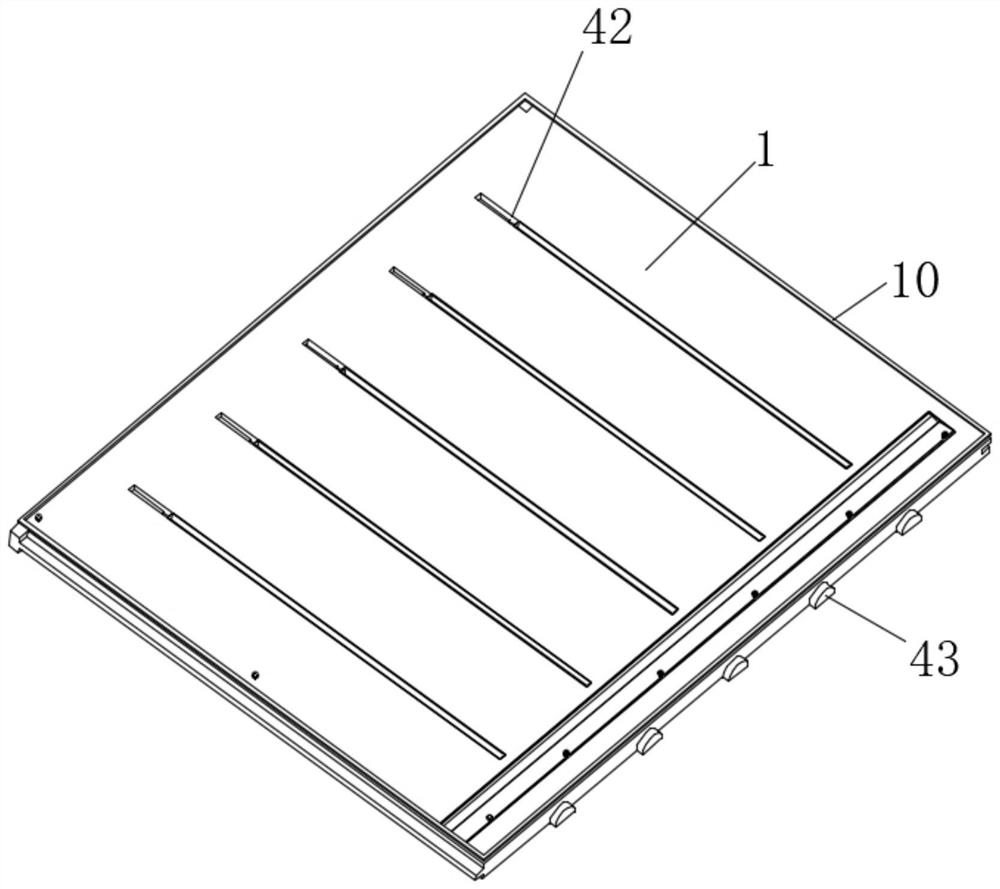

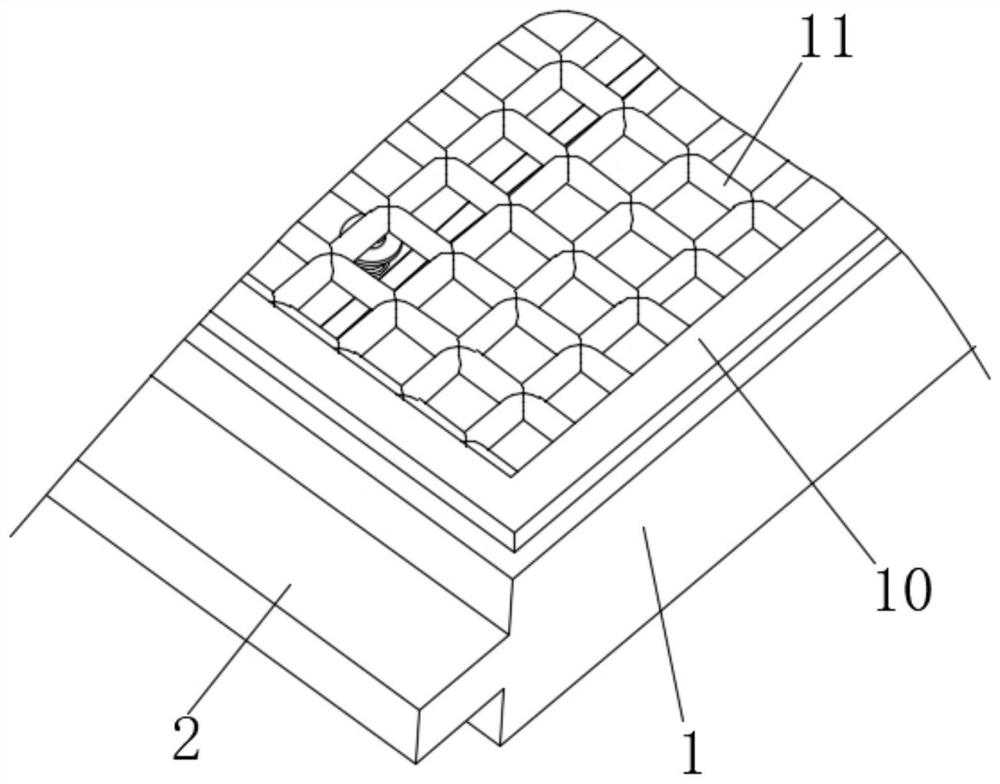

[0032] Such as Figure 1-Figure 11The shown prefabricated green building includes a roof 1, the roof 1 is arranged in several pieces and the edges are spliced together, and the several roofs 1 together form a plate shape with both sides extending obliquely downwards, and the bottom of the top plate 1 is located below. One side is embedded with a water storage cylinder 6, and the upper end port of the water storage cylinder 6 is fixedly installed with an upper angled plate 7 and a lower angled plate 8, and the edges of the upper angled plate 7 and the lower angled plate 8 are close together to form an inclined inlet storage. In the channel inside the water cylinder 6, several anti-evaporation sheets 9 are extended from the lower end surface of the lower cut corner plate 8, and the lower end surface of the top plate 1 is embedded with a water diversion tube 36, and one end of the water diversion tube 36 is movably inserted into the inner side of the water storage tube 6, and th...

Embodiment 2

[0034] A prefabricated green building, comprising a roof 1, the roof 1 is arranged in several pieces and the edges are movably spliced together, the several roofs 1 jointly form a plate shape with both sides extending obliquely downward, and the side near the bottom of the top plate 1 is embedded and installed There is a water storage cylinder 6, and the upper end port of the water storage cylinder 6 is fixedly installed with an upper angled plate 7 and a lower angled plate 8, and the edges of the upper angled plate 7 and the lower angled plate 8 are adjacent to form an inclined opening into the inner side of the water storage cylinder 6. Several anti-evaporation sheets 9 are extended from the lower end surface of the lower angled plate 8, and the lower end surface of the top plate 1 is embedded with a water diversion tube 36, and one end of the water diversion tube 36 is movably inserted into the inner side of the water storage tube 6, and the other side of the water diversio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com