Spraying cooling method and cooling system for thick and large cavity transparent film lighting roof

A lighting roof, spray cooling technology, applied in the field of cooling systems, can solve the problems of limiting the cooling effect and energy saving potential, wasting water resources, ignoring reasonable determination and operation control strategies, etc., to increase the cooling effect and energy saving potential, convenient and convenient Easy installation and maintenance, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

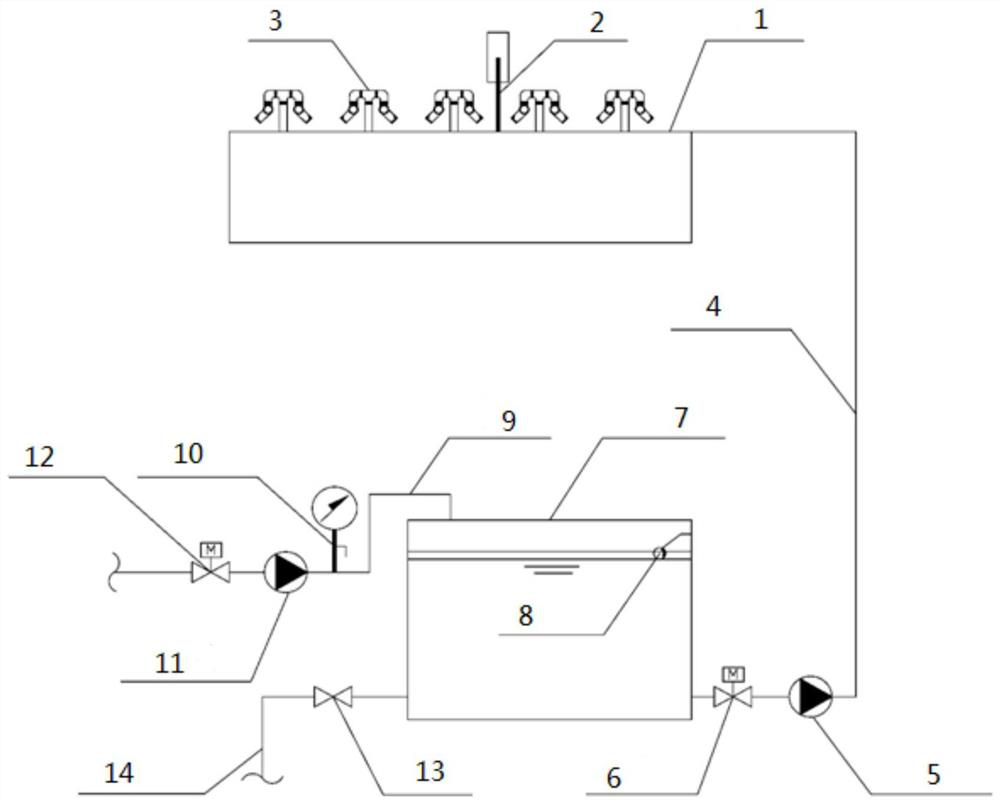

[0032] The present invention will be further described below in conjunction with drawings and embodiments.

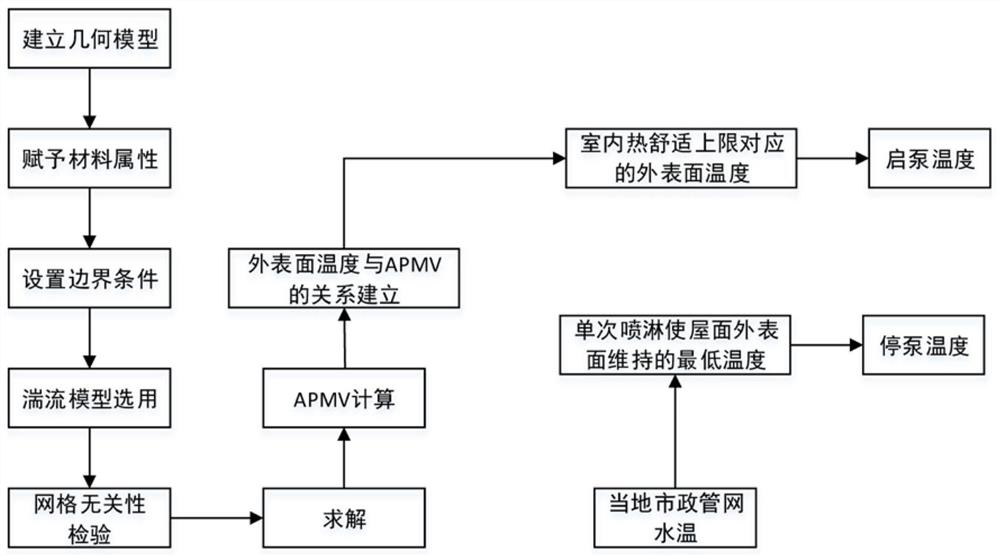

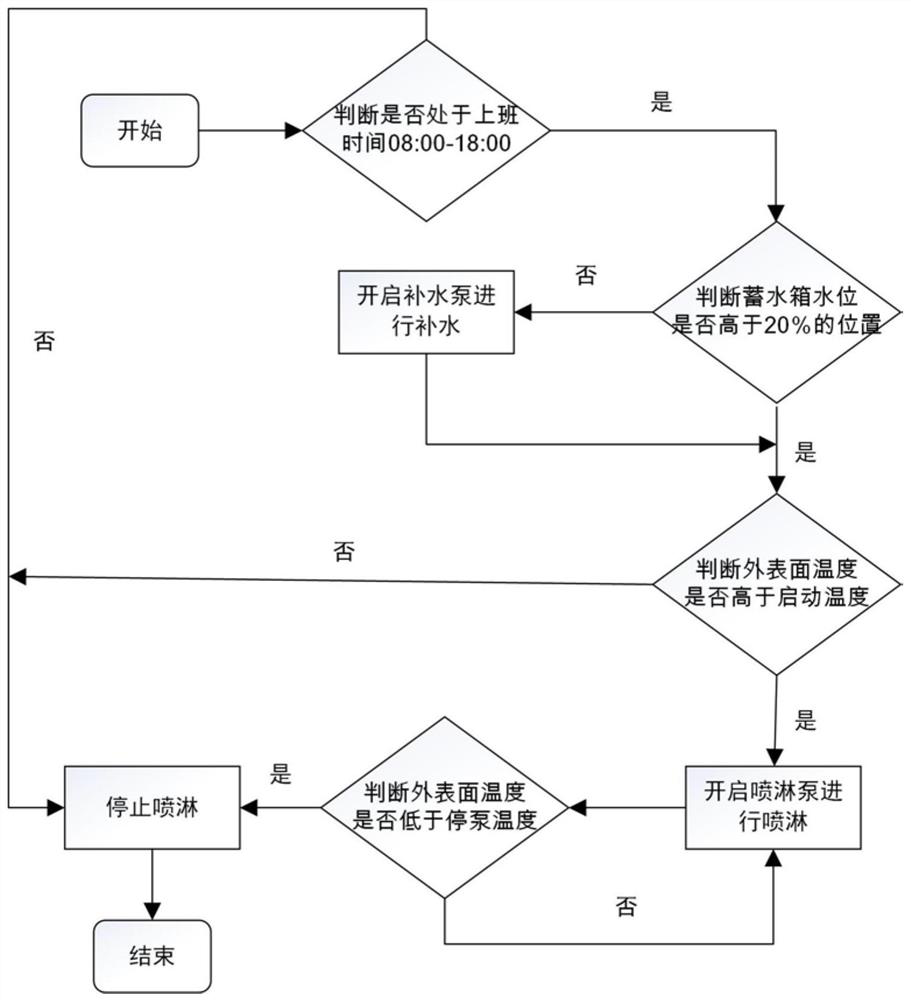

[0033] Such as figure 2 and image 3 As shown, a method for spraying and cooling the roof with thick and large cavity transparent film daylighting, comprising the following steps:

[0034] The building automation system determines whether it is working time according to the timer; if the working time is set to 08:00-18:00, if it is not working time, the cooling system will not operate;

[0035] If it is during working hours, determine the real-time temperature of the outer surface of the roof through the temperature sensor installed on the outer surface of the roof, and judge whether the real-time temperature is higher than the pump start temperature;

[0036] If the real-time temperature is higher than the start-up temperature, before starting the spray pump, first determine the water level of the water storage tank. If the water level of the water storage tank is l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com