Online multi-parameter detection method for special-shaped film holes of engine flame tube

A detection method and technology of air film holes, which are used in measuring devices, instruments, optical devices, etc., can solve the problems that limit the development of air film hole processing technology. , real-time detection of spatial azimuth angle, etc., to achieve huge economic benefits and social value, improve reliability and stability, and high yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

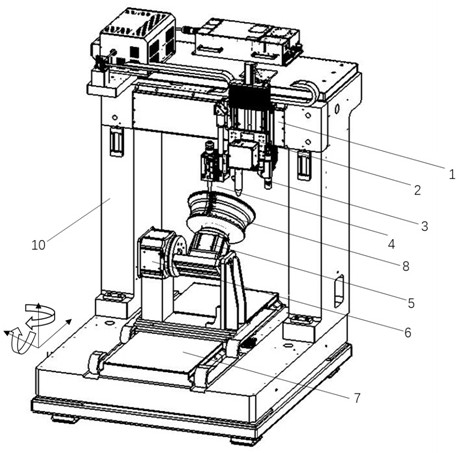

[0041] See attached figure 1 , carry out online multi-parameter detection and error analysis on the gas film hole of the flame tube according to the following steps:

[0042] (1), clamping and positioning

[0043] Assemble the flame cylinder in the special fixture of the flame cylinder positioning device 8 and fix it on the five-axis precision translation table. In order to ensure the reliability of processing and measurement, the design and production of the special fixture must be strictly consistent with the model of the flame cylinder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com