Ultrasonic detection device for detecting aviation rivets

An ultrasonic detection and rivet technology, applied in the direction of measuring devices, using sound waves/ultrasonic waves/infrasonic waves to analyze solids, using sound waves/ultrasonic waves/infrasonic waves for material analysis, etc., can solve the problems of low detection efficiency and achieve the effect of improving detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

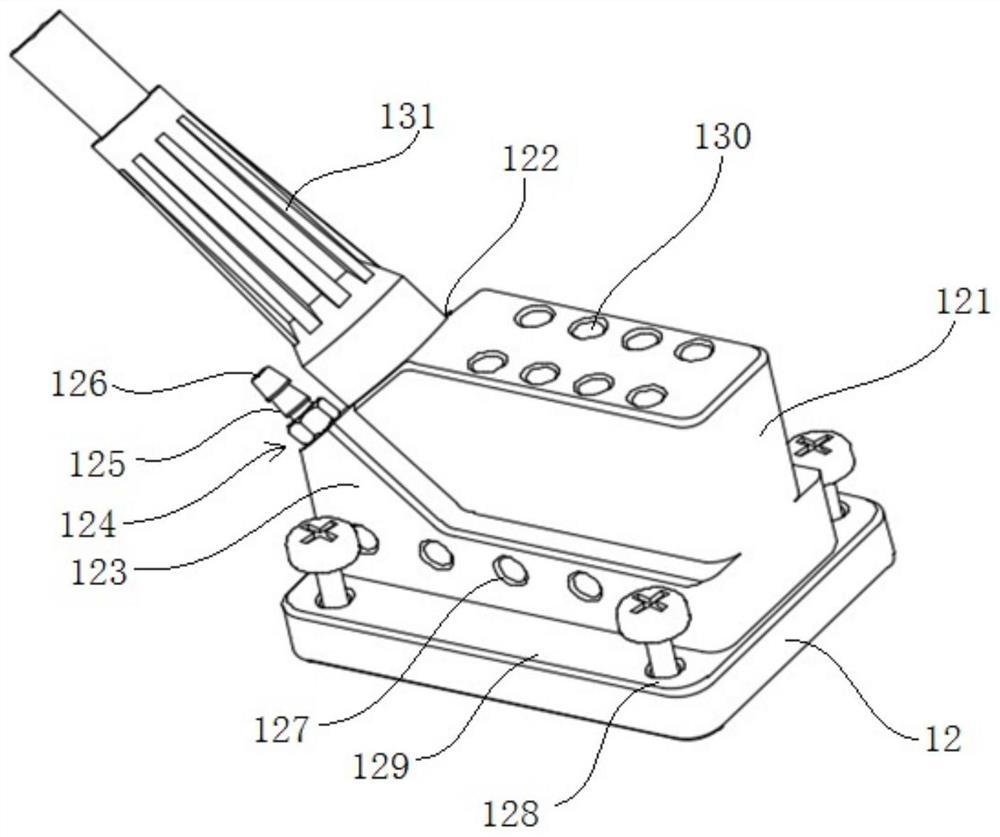

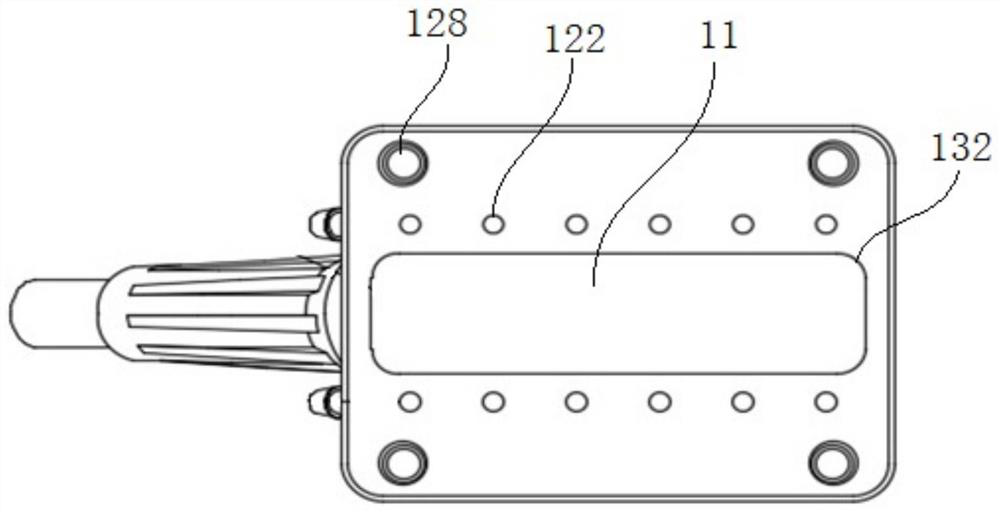

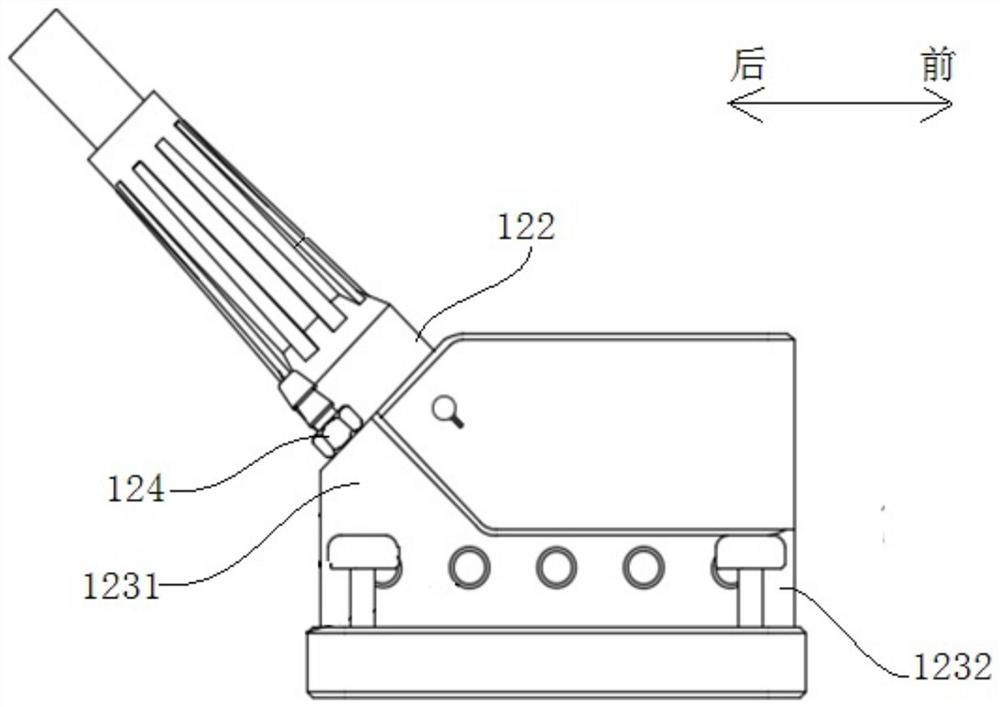

[0032] This embodiment proposes an ultrasonic testing device 1 for testing aviation rivets, such as Figure 1-Figure 3 As shown, it includes an ultrasonic transducer 11 and a base 12. The lower surface of the base 12 is provided with an assembly port 132 and several couplant spray ports 122. The port 122 communicates with a couplant channel 123 , and the couplant channel 123 also has a couplant replenishment port 124 .

[0033] Ultrasonic transducer 11 utilizes the propagation characteristics determined by the high frequency and short wavelength of ultrasonic waves, the uniform propagation of ultrasonic waves in parts, and the characteristics of reflection and refraction when encountering interfaces during propagation, so that defects in workpieces can be found. When there is no damage in the workpiece, the sound wave goes directly to the bottom surface of the workpiece, and is fully reflected back when it meets the interface. When there is a flaw in the workpiece perpendicul...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap