MOF-based platinum monatomic catalyst, and preparation and application thereof

A catalyst and atom technology, which is applied in the field of electrochemical energy, achieves the effects of simple preparation method, reduced cost, and favorable promotion and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] A kind of preparation method of MOF-based platinum single-atom catalyst provided by the invention comprises the following steps:

[0032] Step S1, adding zirconium chloride, 2-aminoterephthalic acid and platinum source to the mixed solution of DMF and adjusting acid, heating for reaction, washing after cooling, and then drying the washed material to obtain a dry material ;

[0033] Step S2, performing high-temperature carbonization on the dry material at 800°C to 1000°C in an inert gas atmosphere to obtain a carbonized substance;

[0034] Step S3, soaking the carbonized substance with etching acid, and washing to obtain a MOF-based platinum single-atom catalyst.

[0035] In the above step S1, the molar ratio of zirconium chloride, 2-aminoterephthalic acid and platinum source is 0.9:0.9:0.5-3. The platinum source is any one of chloroplatinic acid, platinum acetylacetonate or platinum dichloride. In the present invention, only chloroplatinic acid and platinum acetylace...

Embodiment 1

[0044] In this example, the platinum source is chloroplatinic acid, and the obtained MOF-based platinum single-atom material is Pt(IV)-SACs material.

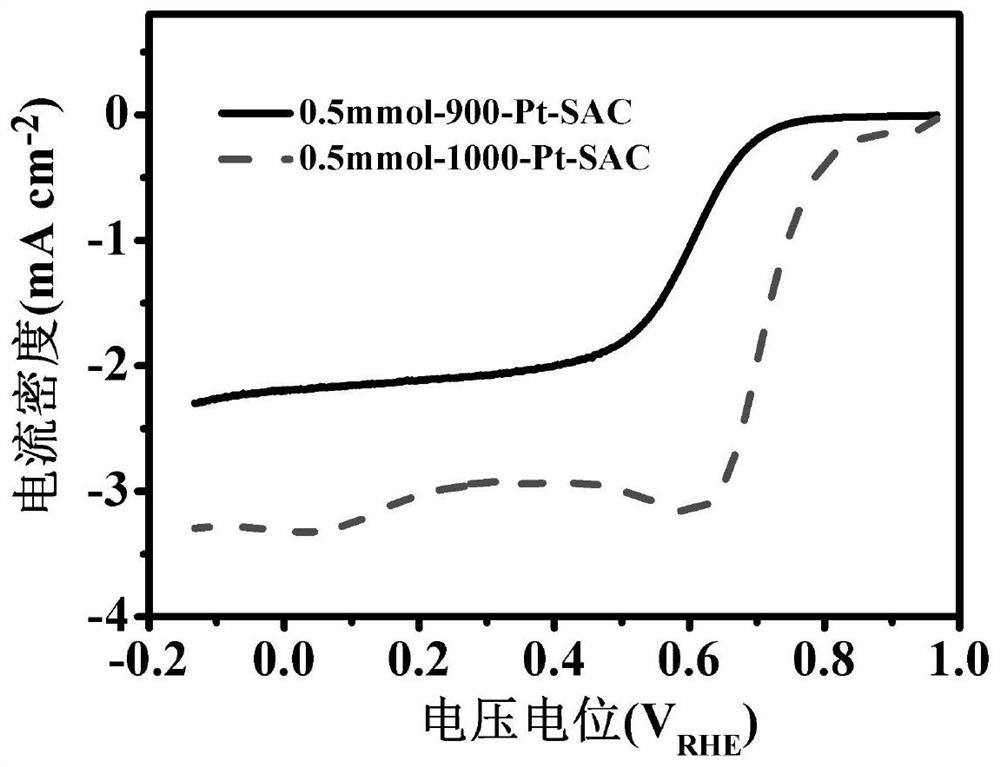

[0045] Dissolve 210 mg of zirconium chloride, 163 mg of 2-aminoterephthalic acid, and 0.5 mL (solvent: DMF; concentration: 1 mg / mL) of chloroplatinic acid in 40 mL of dimethylformamide and 4.8 mL of glacial acetic acid, and fill in vials React in an oven at 120°C for 12 hours, cool the reaction with V 甲醇 :V DMF =1: 4 washes 3 times and centrifuged at 8000rpm for 5 minutes; vacuum-dried the centrifuged and washed material at 60°C for 12h; treated the dried sample at 900°C for 3h under a nitrogen atmosphere, and then naturally cooled to room temperature to obtain The catalyst material; the high-temperature-treated material was soaked in 5% HF solution for 2h, washed with water again for 3 times and centrifuged at 8000rpm for 5 minutes, and the washed material was vacuum-dried for 12h at 60°C to obtain a MOF-based platinum single...

Embodiment 2

[0047] In this example, the platinum source is chloroplatinic acid, and the obtained MOF-based platinum single-atom material is Pt(IV)-SACs material.

[0048] Dissolve 210mg of zirconium chloride, 163mg of 2-aminoterephthalic acid and 0.5mL (1mg / mL) of chloroplatinic acid in 40mL of dimethylformamide and 4.8mL of glacial acetic acid, put them in vials and react in an oven at 120°C 12h, after the reaction is cooled, use V 甲醇 :V DMF = 1: 4 washes 3 times and centrifuged at 8000rpm for 5 minutes; the centrifuged and washed material was vacuum-dried at 60°C for 12h; the dried sample was treated at 1000°C for 3h under a nitrogen atmosphere, and then naturally cooled to room temperature to obtain The catalyst material; the high-temperature-treated material was soaked in 5% HF solution for 2h, washed with water again for 3 times and centrifuged at 8000rpm for 5 minutes, and the washed material was vacuum-dried for 12h at 60°C to obtain a MOF-based platinum single-atom catalyst (Pt ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com