Flexible dragging method of oil pumping unit

A kind of oil pumping unit and flexible technology, which is applied in the field of flexible dragging of oil pumping units, and can solve the problems of not completely solving the problem and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

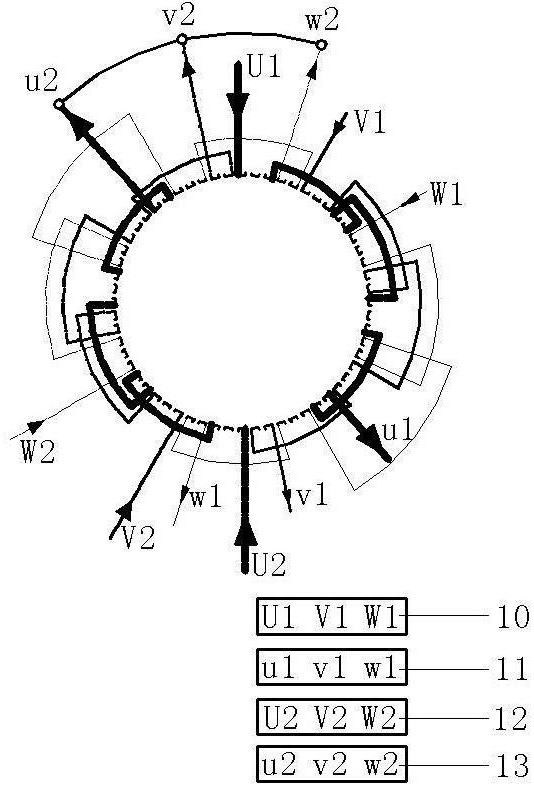

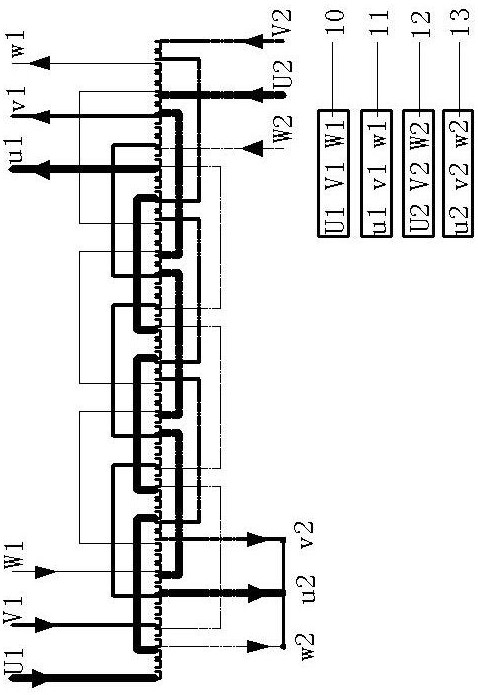

[0015] A flexible dragging method of a pumping unit according to the present invention is to design the stator winding 8 in the AC motor casing 1 as two independent star-connected windings, and when the pumping unit is started, the two independent star-connected windings are connected to the power grid in parallel After starting, the two independent star-connected windings are automatically connected to the grid in series.

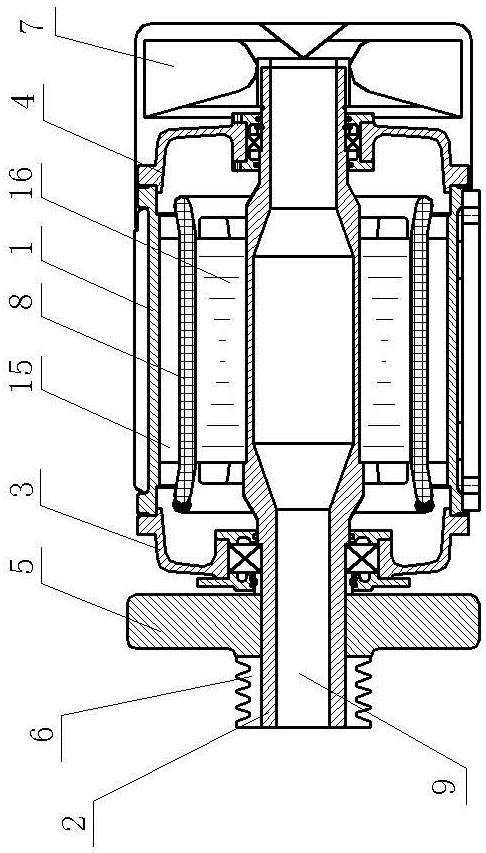

[0016] The AC motor includes a housing 1, a rotor shaft 2, a front end cover 3 and a rear end cover 4, and a transmission pulley 6, a flywheel 5, a front end cover 3, a housing 1, and a stator are sequentially set on the rotor shaft 2 from front to back. 15. The rotor 16, the rear end cover 4 and the self-cooling fan 7; at the same time, the rotor shaft 2 of the AC motor is designed as a hollow rotor shaft to replace the yoke part of the lamination, and the rotor 16 of the AC motor has a frequency-sensitive variable frequency integrated with the rotor shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com