Preparation method of tobacco raw material for heating cigarettes and heated cigarette product

A technology for tobacco and raw materials, applied in the directions of tobacco, tobacco processing, application, etc., can solve the problems of high irritation, uneven nicotine release, and large nicotine content, and achieve less irritation, lower nicotine release, and aroma quality. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

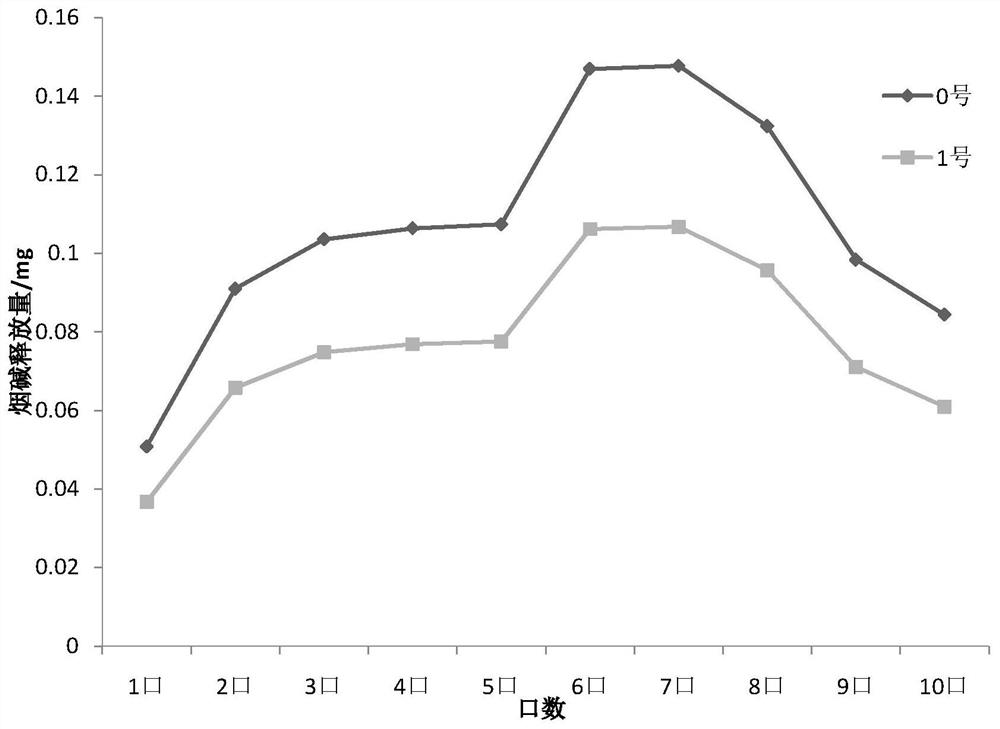

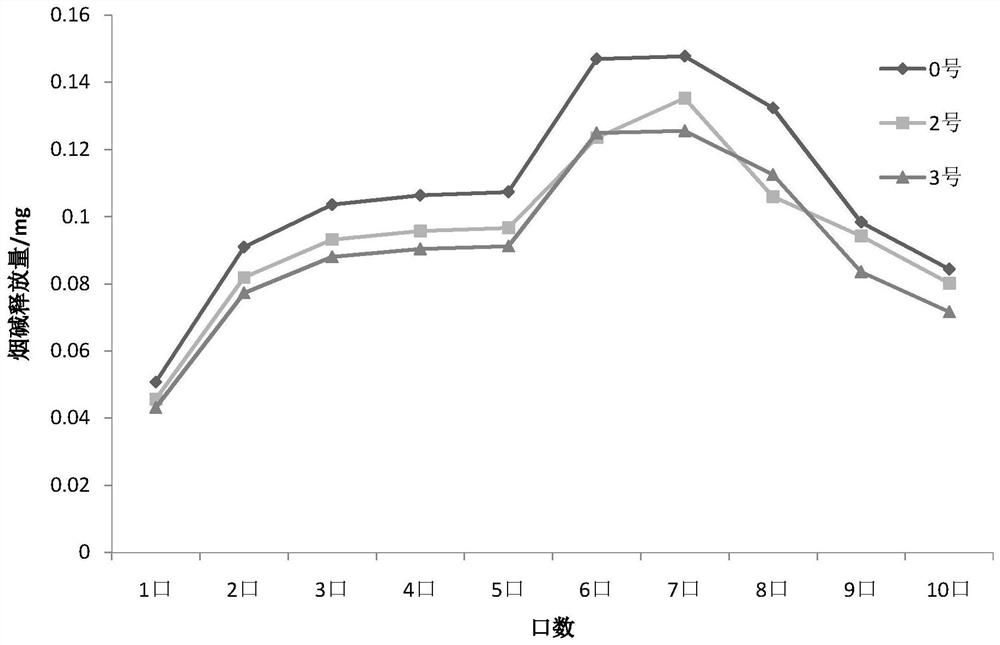

[0023] 10 grams of water and 5 grams of gallic acid are prepared as a gallic acid solution and sprayed on 100 g of shredded tobacco; 5 grams of hydroxypropyl cyclodextrin and 5 grams of alcohol are prepared as a cyclodextrin solution and sprayed on the 100 g of shredded tobacco ; Placed at 50°C for 10 hours, rolled the shredded tobacco into a heated cigarette stick, smoked in a heated cigarette appliance, and smoked in a two-stage heated heat-not-burn appliance, and analyzed the release of nicotine in the smoke aerosol Condition. See figure 1 .

[0024] From figure 1 It can be seen from the figure that the release of nicotine in the first three puffs of the smoke aerosol in the original sheet during the first heating process is quite different, especially the difference between the first puff and the third puff . The amount of nicotine in the sixth puff of smoke increased rapidly during the second stage of heating. However, for shredded tobacco added with gallic acid and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com