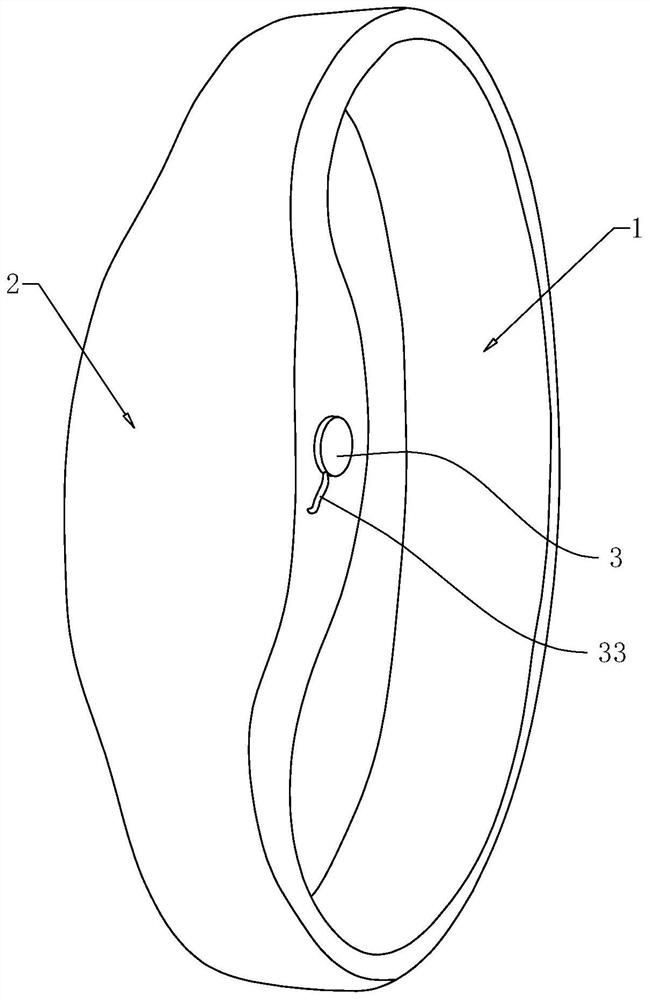

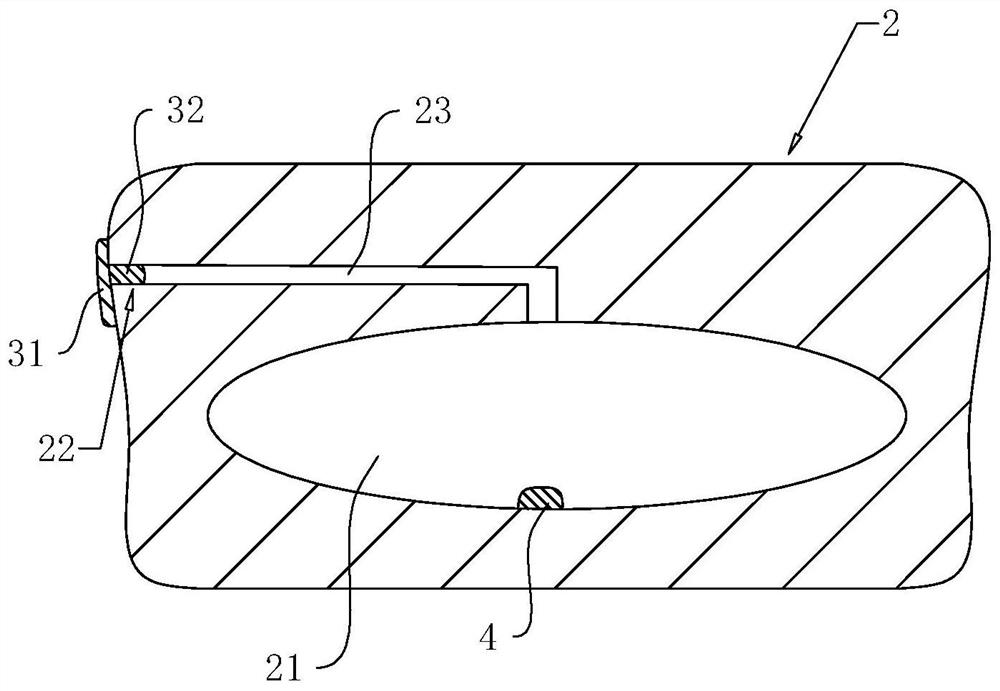

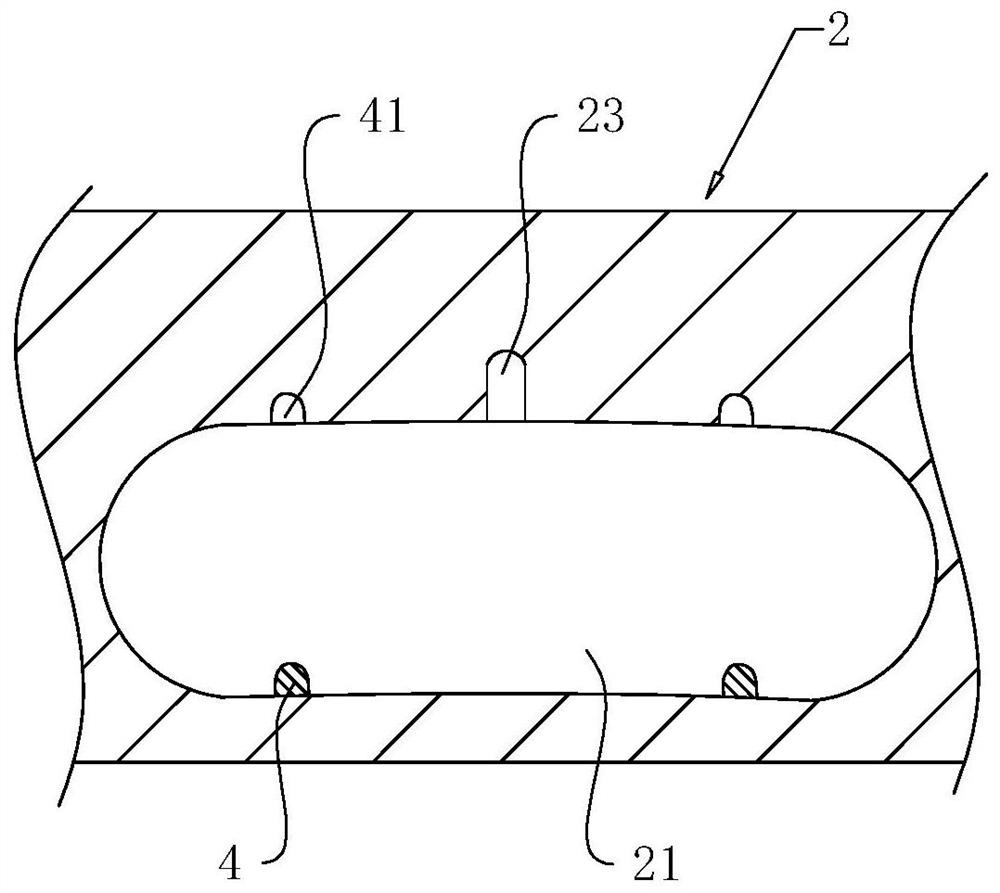

Cleaning type silica gel wrist strap and production process thereof

A clean, wristband technology, applied in watch bands, applications, clothing, etc., can solve the problems of single function of silicone wristbands and insufficient function development of silicone wristbands, achieve diversification of functions, and improve the ability to tolerate alcohol , the effect of increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0057] Preparation of polystyrene modified nano silica:

[0058] Mix 1000g of nano-silica and 10kg of ethanol, add 300g of KH550 dropwise at 55°C for 1 hour, continue stirring for 3 hours, filter and dry in an oven at 55°C for 1 hour to obtain KH550 modified nano-silica ;

[0059] Mix 10g of azobisisobutyronitrile and 500g of ethanol to form a catalyst solution, mix 1000g of KH550 modified nano-silica, 1500g of styrene, 200g of polyvinylpyrrolidone, 100g of water and 9.5kg of ethanol, then add dropwise at 50°C After the catalyst solution was added dropwise for 1 hour, the stirring reaction was continued for 7 hours. After the reaction, it was filtered and dried in an oven at 55° C. for 1 hour to obtain polystyrene-modified nano-silica.

preparation example 2

[0061] Preparation of polystyrene modified nano silica:

[0062] Mix 1000g of nano-silica and 12kg of ethanol, add 450g of KH550 dropwise at 70°C for 1 hour, continue stirring for 1 hour, filter and dry in an oven at 55°C for 1 hour to obtain KH550 modified nano-silica ;

[0063] Mix 20g of azobisisobutyronitrile and 500g of ethanol to form a catalyst solution, mix 1000g of KH550 modified nano-silica, 2000g of styrene, 400g of polyvinylpyrrolidone, 300g of water and 11.5kg of ethanol, then add dropwise at 65°C After the catalyst solution was added dropwise for 1 hour, the stirring reaction was continued for 9 hours. After the reaction, it was filtered and dried in an oven at 55° C. for 1 hour to obtain polystyrene-modified nano-silica.

preparation example 3

[0065] Preparation of polystyrene modified nano titanium dioxide:

[0066] Mix 1000g of nano-titanium dioxide and 12kg of ethanol, add 450g of KH550 dropwise at 70°C for 1 hour, continue stirring for 1 hour, filter and dry in an oven at 55°C for 1 hour to obtain KH550 modified nano-titanium dioxide;

[0067] Mix 20g of azobisisobutyronitrile and 500g of ethanol to form a catalyst solution, mix 1000g of KH550 modified nano titanium dioxide, 2000g of styrene, 400g of polyvinylpyrrolidone, 300g of water and 11.5kg of ethanol, then add the catalyst solution dropwise at 65°C After 1 hour of dropwise addition, continue to stir and react for 9 hours. After the reaction, filter and dry in an oven at 55° C. for 1 hour to obtain polystyrene-modified nano-titanium dioxide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com