High-precision machining device and control method thereof

A technology of high-precision processing and control methods, applied in positioning devices, metal processing equipment, metal processing machinery parts, etc., can solve the problems of tray loss, heavy weight, labor, etc., to improve positioning performance, improve fixation, and ensure processing accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

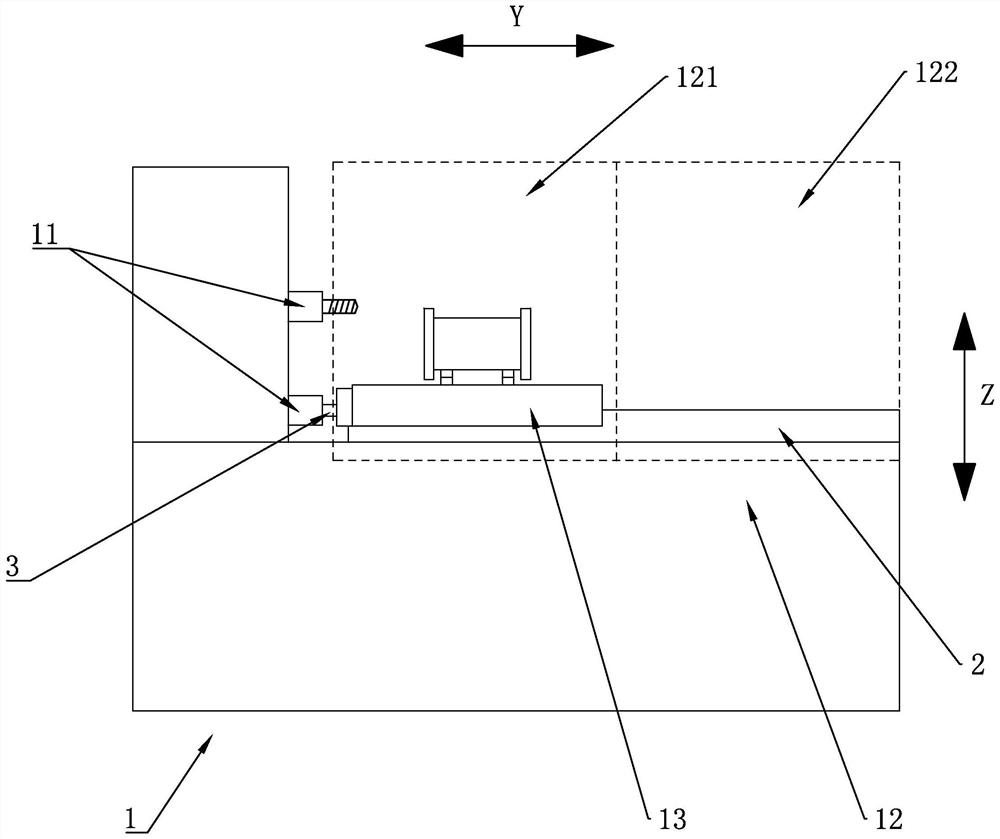

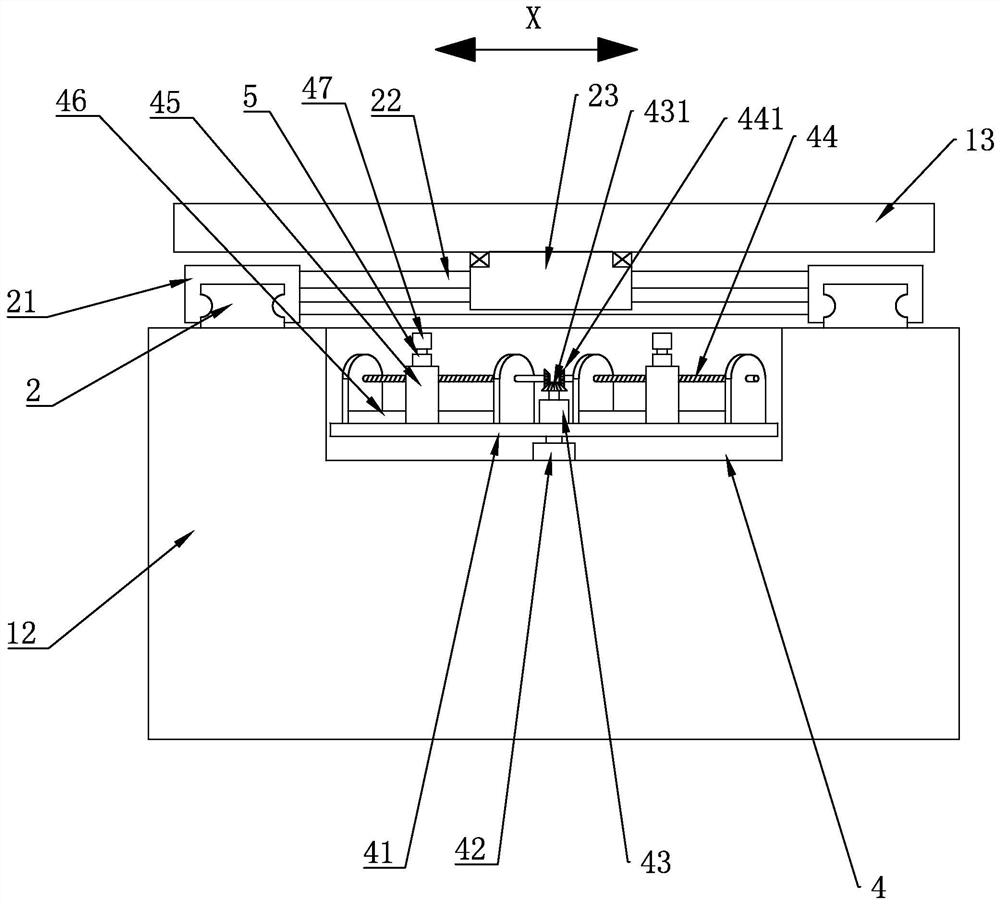

[0033] In order to enable those skilled in the art to better understand the technical solutions in the present invention, the following in conjunction with the attached Figure 1 to Figure 9 A clear and complete description of the technical solutions in the embodiments of the present invention:

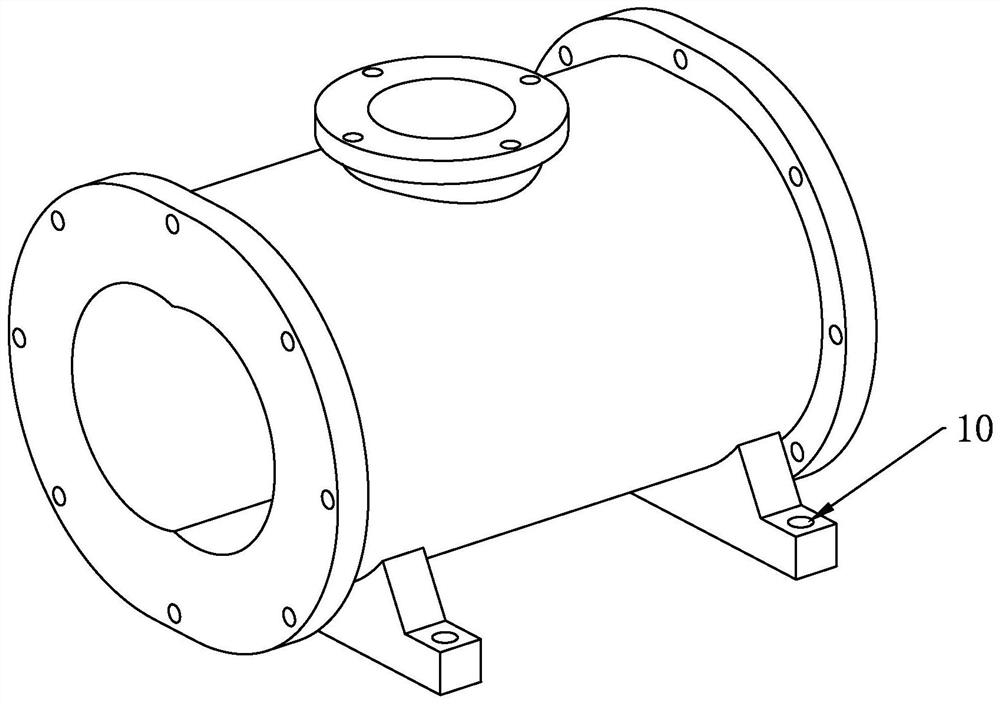

[0034] A high-precision processing device, including a machine tool body 1, at least one tool holder 11 placed on the machine tool body 1 and used for installing a tool, a workbench 12, and a pallet 13 for supporting a workpiece. The tool holder 11 facilitates the installation of tools and The coupling 3, the machine tool body 1 is fixedly connected with the workbench 12, and has high structural strength. The tray 13 is used to carry the air compressor shell and ensure the stable placement of the air compressor shell. During the processing process, the tray 13 Clamped on the workbench 12 to further improve the machining accuracy, the tool holder 11 is used to install the tool or the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com